Permanently-uvioresistant light fabric

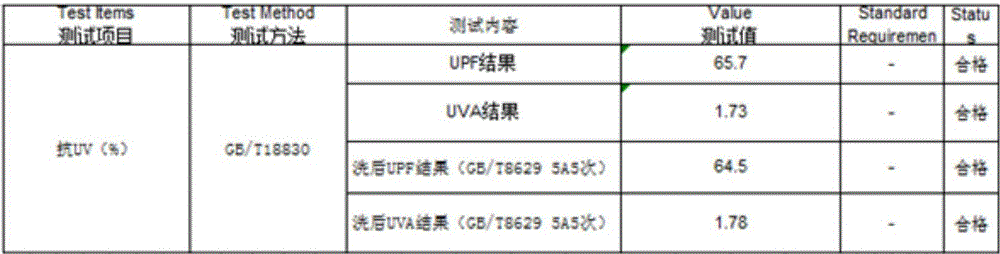

An anti-ultraviolet and permanent technology, applied in textiles, woven fabrics, fabrics, etc., can solve the problems of poor absorption of anti-ultraviolet shielding agents, difficulty in anti-ultraviolet durability, difficulty in meeting the requirements of fabric strength, etc., to achieve enhanced reflection of ultraviolet rays High performance, reduced penetration, and strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

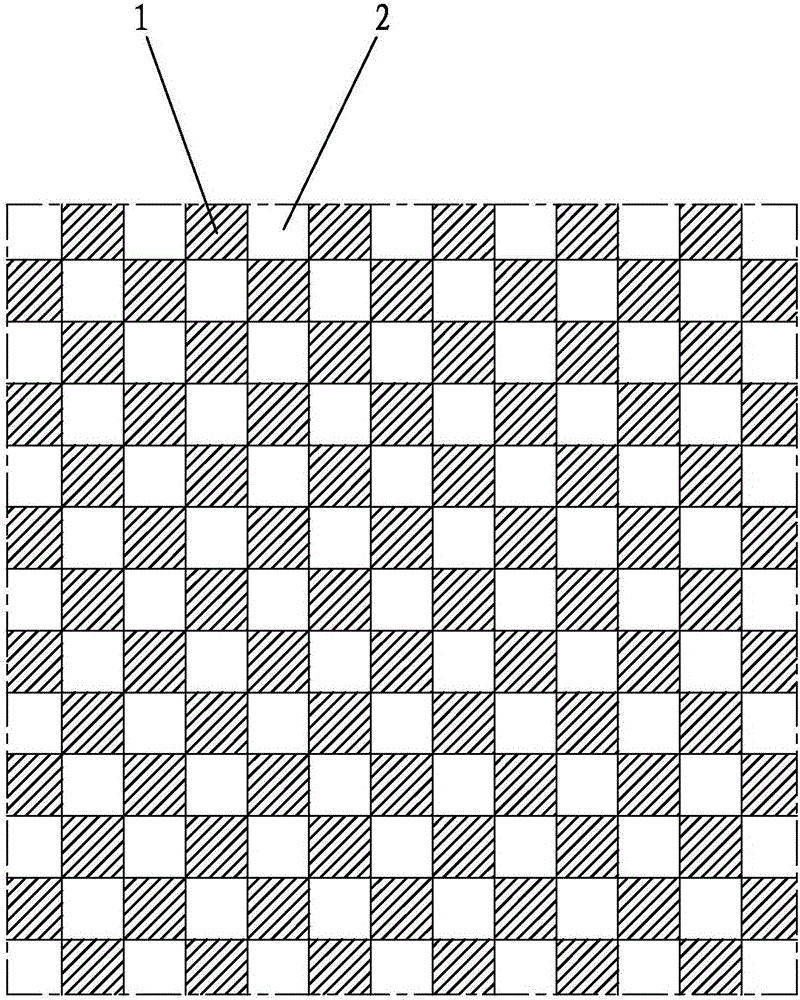

[0036] A kind of permanent anti-ultraviolet frivolous fabric of the present invention, as figure 1 and 2 As shown, warp 1 and weft 2 are included.

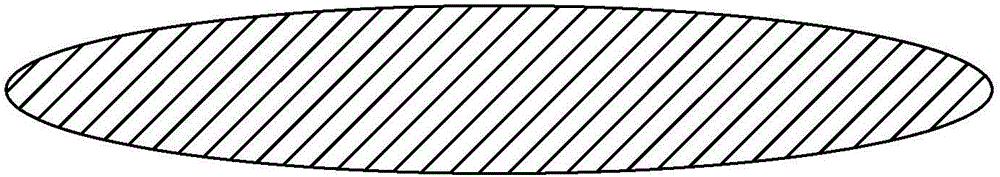

[0037] At least one of the warp yarn 1 and the weft yarn 2 is a full-dull polyester yarn with a flat cross section, and the plane of the full-dull polyester yarn faces the front of the fabric.

[0038] The flat cross-section full-dull polyester yarn is called flat yarn, which is a new type of Vicat fiber with a flat cross-section that is spun by a special process. It combines the excellent properties of ordinary Vicat fiber and hemp fiber. The fabric is smooth, elastic and soft, rich in three-dimensionality, comfortable and pleasant; it has the characteristics of moisture absorption and heat dissipation, and is easier to dye. A special high-ratio inline spinneret is used to produce po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com