Carbon fiber multi-layer angle connection loom yarn tension control method

A technology of yarn tension and corner looms, applied to looms, multi-strand fabrics, fabrics, etc., can solve the problems of reduced weaving efficiency, increased warp tension interference, high strength, high modulus, and poor wear resistance, and achieves well formed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. However, the protection scope of the present invention is not limited to the scope expressed in the embodiments.

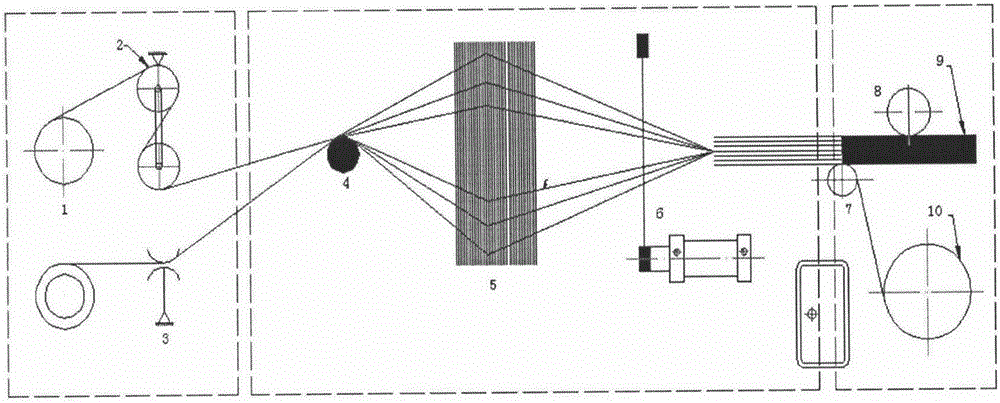

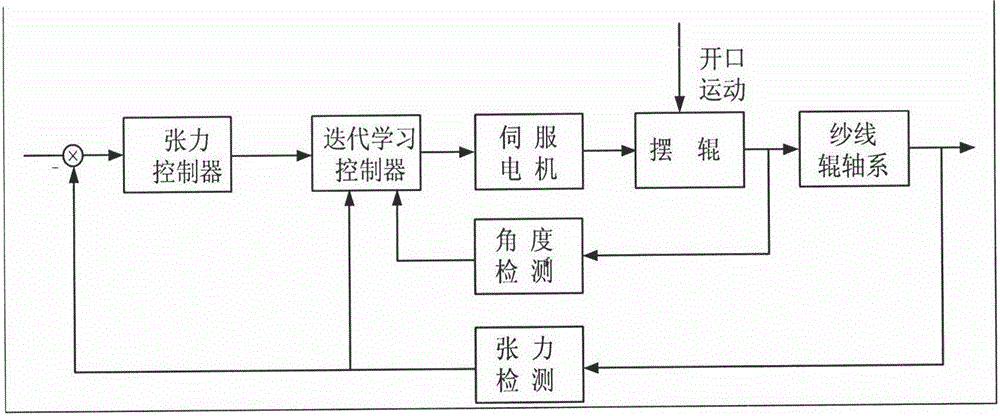

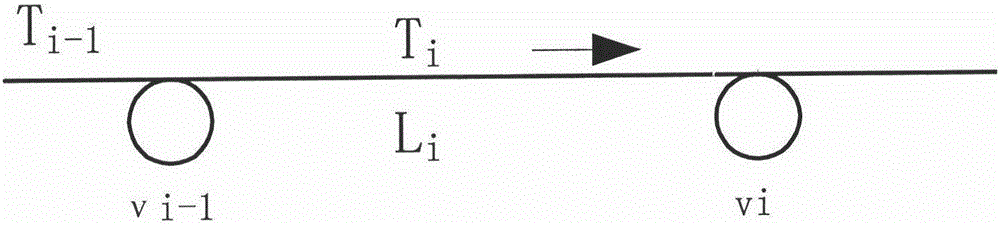

[0019] According to the working principle of the loom figure 1 , the warp system is divided into six areas according to the conveying process, and the distribution of warp parameters is shown in Figure 4 As shown, before modeling the dynamics of the let-off system, the parameters such as speed and tension in the system are expressed separately, in the figure T i is the tension of the carbon fiber warp within the roller span, L i is the length of the carbon fiber warp in the span, V i is the rotational speed of the roller shaft.

[0020] introduce as image 3 A generic model for the tension of the strip-like material is shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com