Underwater concrete grouting pile top elevation control construction method

An underwater concrete and construction method technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of insufficient effective length of cast-in-place pile body, increased pile head removal workload, and inability to achieve accuracy, etc. Significant social benefits, guaranteed strength and overall stability, and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method of the present invention is described in detail below with reference to the accompanying drawings.

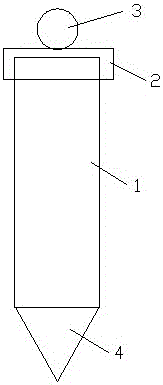

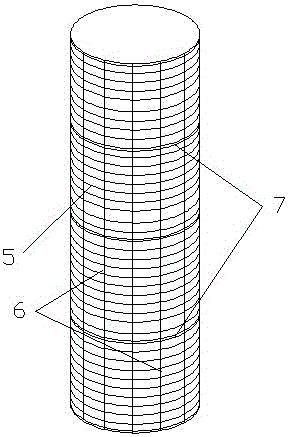

[0015] A construction method for controlling the elevation of the pile top of an underwater concrete pouring pile. With the help of an underwater concrete pouring height measuring instrument, when pouring underwater concrete, the concrete of the same condition is poured into the prefabricated elevation measuring instrument, so that the elevation measuring instrument The self-weight is slightly lower than the weight of concrete with the same volume, the specific gravity of mud is 1.1mg / mm3, and the specific gravity of concrete is 2.4mg / mm3. Because its buoyancy in the mud is slightly smaller than its buoyancy in concrete, the height measuring instrument is placed in the pile hole, and its position is just at the junction of the mud and underwater concrete. The buoyancy is different. With the underwater concrete pouring, the height measuring instrument rises acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com