An intelligent digging pipe jacking machine

A technology of pipe jacking machine and excavating arm, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of low automation level, low production efficiency, threats to personnel and equipment safety, etc., and achieve the level of intelligence and intensification High, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

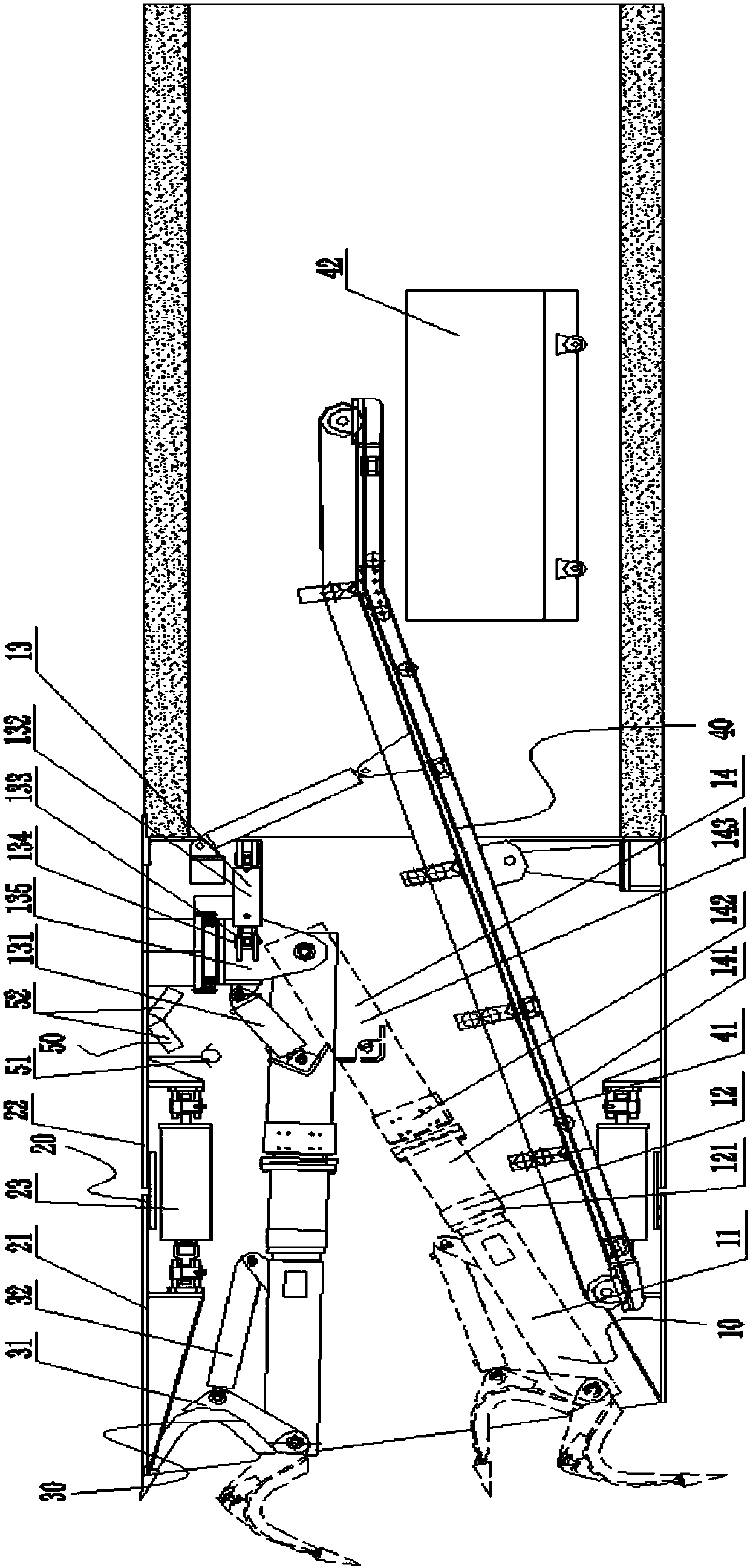

[0027] see Figure 1-Figure 3 .

[0028] An intelligent excavating pipe jacking machine of the present invention comprises an excavating arm assembly 10, an anti-collapse cylinder assembly 20, a bucket assembly

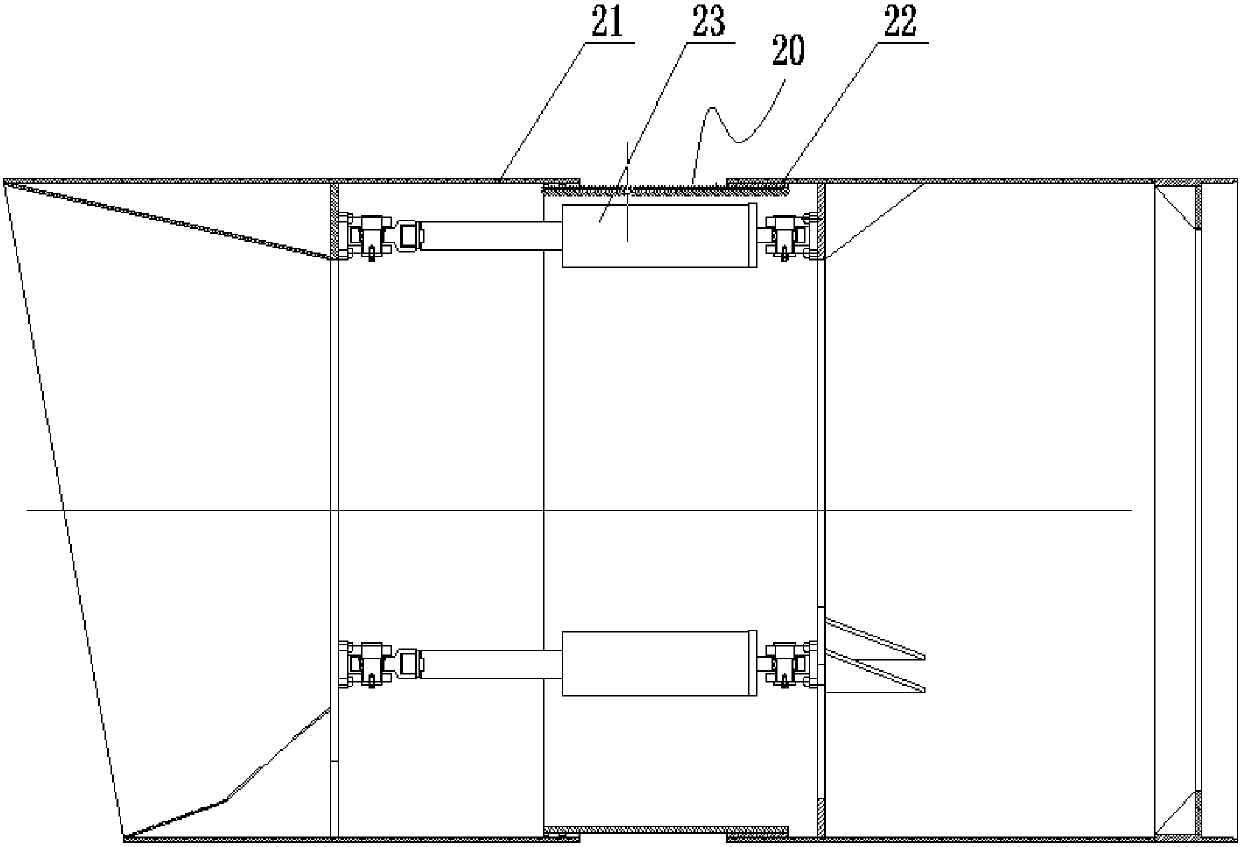

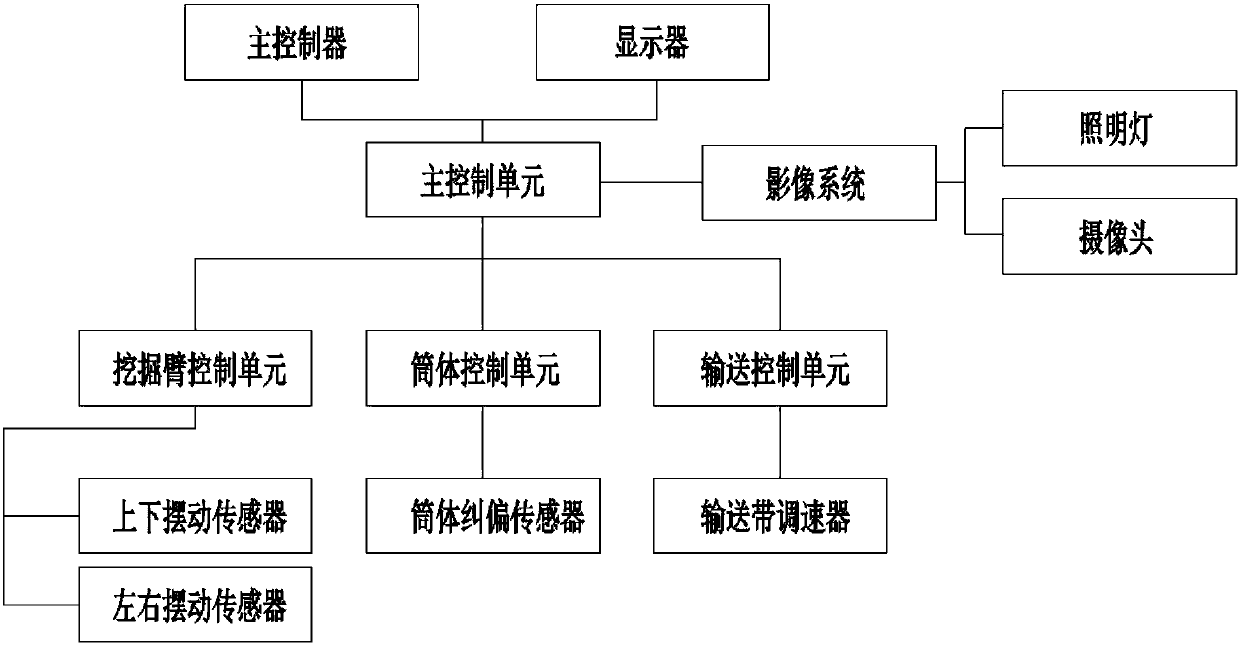

[0029] 30. A conveying mechanism 40, a control system and an imaging system 50. The excavating arm assembly 10 is arranged in the anti-collapse cylinder assembly 20; the excavating arm assembly 10 includes an excavating arm 11, a rotating unit 12 and a swing unit 13, and the rotating unit 12 is used to drive the The excavating arm 11 rotates freely, and the swing unit 13 is used to drive the excavating arm 11 to swing up and down, left and right; the anti-collapse cylinder assembly 20 includes a front cylinder 21 and a rear cylinder 22, and the front cylinder The body 21 and the rear cylinder 22 are hingedly connected by a deviation-correcting oil cylinder 23, and the front cylinder 21 can extend forward along the rear cylinder 22 to prevent the soil layer from coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com