Bolt assembly suitable for motor installation

A bolt assembly and screw technology, applied in the direction of bolts, threaded fasteners, screws, etc., can solve problems such as the inability to effectively fix vibrating parts such as motors, and achieve the effects of preventing loosening or falling off, high safety performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

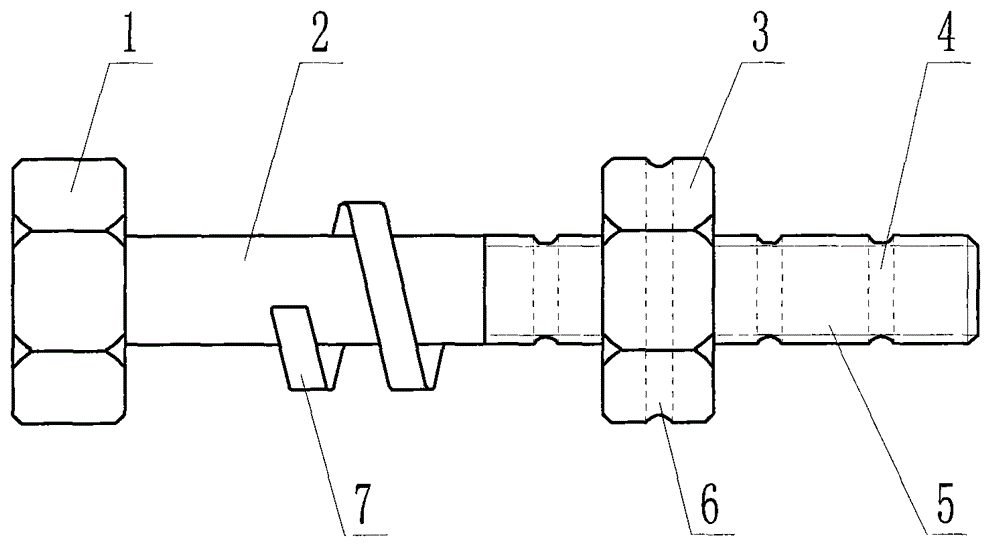

[0014] Such as figure 1 As shown, the bolt assembly suitable for motor installation provided by the present invention includes a screw 2 with a nut 1 at one end, a threaded segment 5 at the other end of the screw 2, and a nut 3 matched with the threaded segment 5. The threaded The section 5 is provided with a number of evenly arranged through holes 4, the nut 3 is provided with a limit hole 6 coaxial with the through holes 4, and the screw rod 2 between the nut 3 and the nut 1 is sleeved with an elastic metal washer 7.

[0015] In order to prevent the pin from intersecting with the motor or the plate during installation, resulting in failure of insertion, the central axis of the through hole 4 is perpendicular to the central axis of the screw rod 2 .

[0016] The inner diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com