Vehicle lamp module and lens

A lens and lamp technology, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of difficult to find plastic materials, increase the length of the back focal length, increase the weight and manufacturing cost, etc., achieve good light diffusion effect, solve dispersion problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The aforementioned and other technical content, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

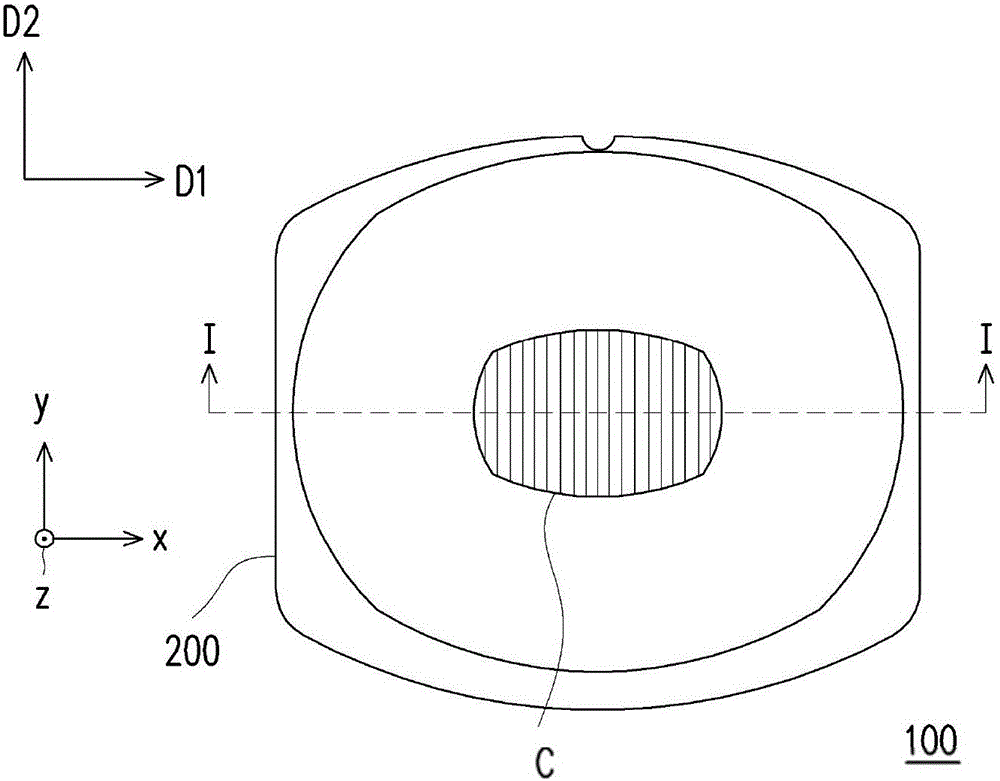

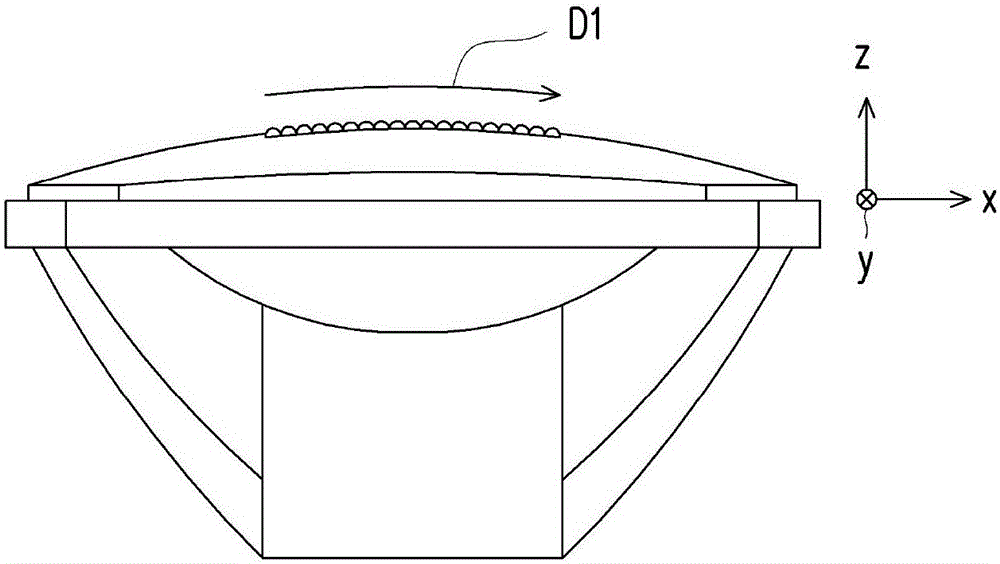

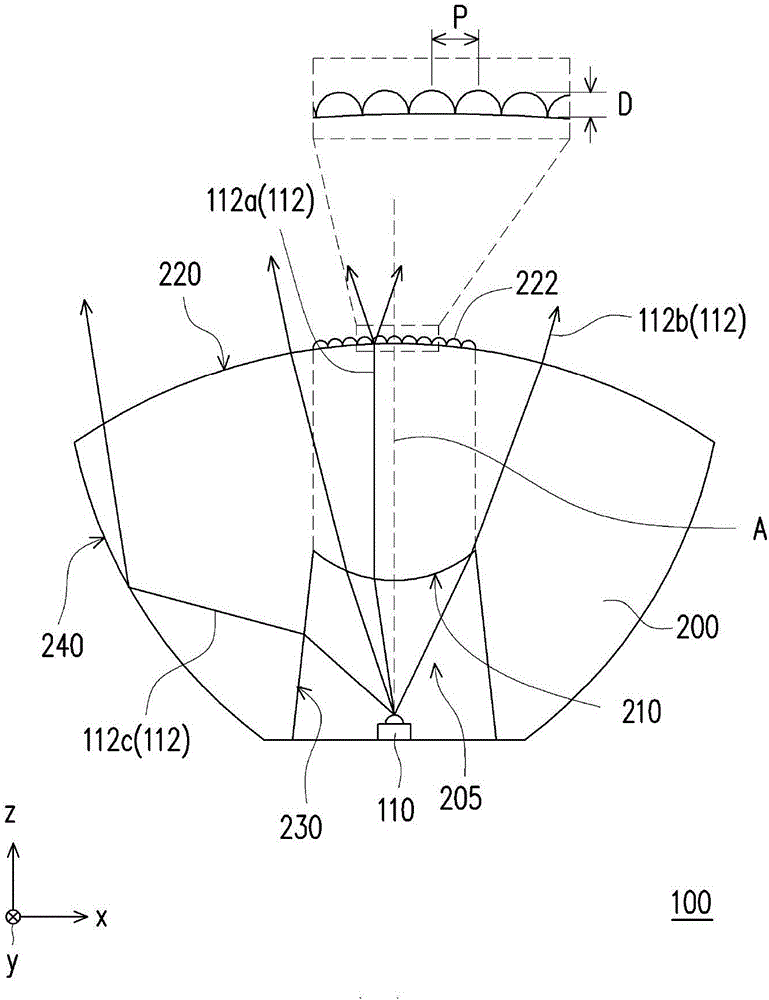

[0030] Figure 1A It is a schematic front view of a vehicle lamp module according to an embodiment of the present invention, Figure 1B for Figure 1A A schematic side view of the headlight module, Figure 1C for Figure 1A The cross-sectional schematic diagram of the car light module along the I-I line, while Figure 1D for Figure 1A 3D schematic diagram of the cylindrical microstructure in . Please refer to Figure 1A to Figure 1D , the vehicle light module 100 of this embodiment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com