Connection mechanism between tubes and tube bases of a heat exchanger and method for producing the connection mechanism

A connection mechanism and heat exchanger technology, applied in heat exchange equipment, heat exchanger shells, lighting and heating equipment, etc., can solve the problems of expensive film and troublesome welding, and achieve the effect of eliminating deformation and achieving shape stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

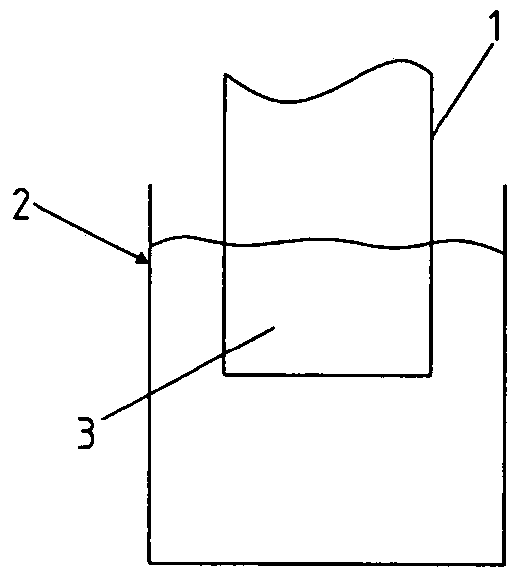

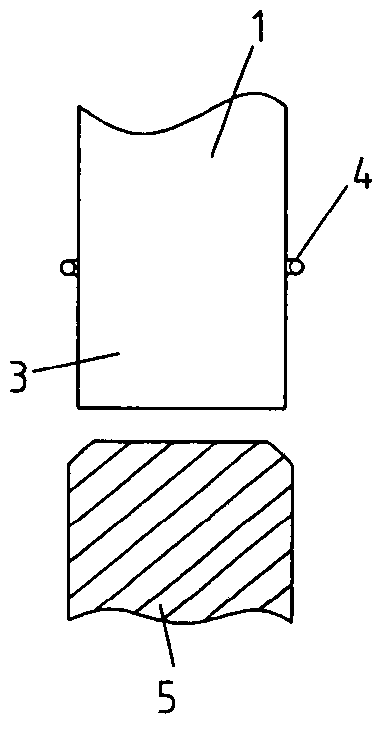

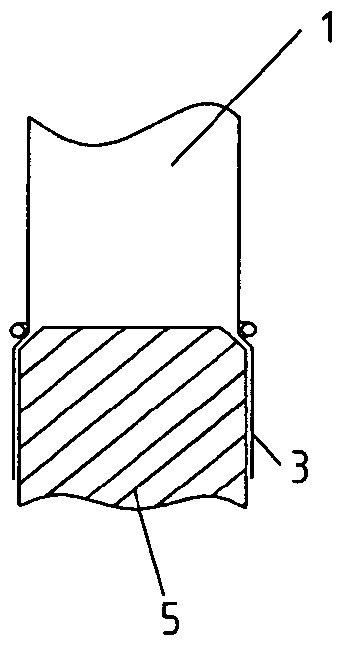

[0047] figure 1 A situation in which a tube 1 made of fluoropolymer plastic is immersed in a salt solution bath 2 is shown. The end section of the tube 1 to be heated should be heated to the softening temperature. If this temperature is reached, the tube 1 is removed from the bath 2. Immediately afterwards, the blocking body 4 in the form of a ring is put on the tube 1. The diameter of the blocking body 4 is only slightly larger than the diameter of the tube 1. At present, the heated end section 3 in a state capable of plastic deformation is positioned on the mandrel 5, which is inserted into the end section 3 so that the end section 3 is expanded in the radial direction ( figure 2 with 3 ).

[0048] Next, the radially enlarged end section 3 is rolled and guided on the blocking body, so that the blocking body is located in a loop 6 which is formed by the rolled end section. The previously heated area cools down and clings to the outside of the tube 1 in a manner not shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com