Thermal type gas mass-flow meter internally provided with rectifier

A gas mass flow and rectifier technology, applied in indirect mass flow meters, mass flow measurement devices, etc., can solve the problems of complicated pipeline distribution, increased pipelines, and reduced instrument use accuracy, reducing pipeline dew point, saving labor costs, and saving The effect of installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the content of the present invention easier to be understood clearly, the following further describes the present invention in detail based on specific embodiments in conjunction with the accompanying drawings.

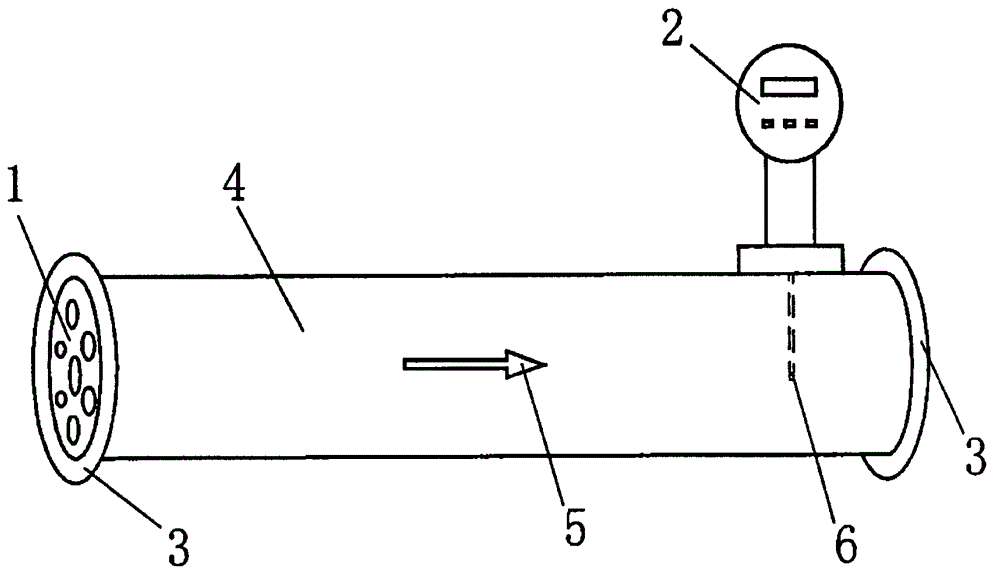

[0014] according to figure 1 , The present invention includes a flow meter pipe 4, a flow measuring part 2, a rectifier 1. The flow meter pipe 4 has a built-in rectifier 1 at the front end to enable it to set the flow field. The flow meter pipe 4 and the rectifier 1 are welded together as As a whole, the distance between the rectifier 1 and the flow measuring part 2 is 3 to 5 times the diameter of the flow meter pipe 4. The two ends of the flow meter pipeline 4 are provided with connecting flanges 3 for connection with the process pipeline. The plug-in probe 6 of the flow measuring part 2 is inserted into the flow meter pipe 4, and the flow measuring part 2 is welded to the flow meter pipe 4 as a whole. The flow meter pipe 4 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com