Hypersonic speed wind-tunnel nozzle outlet segment water cooling device

A technology of nozzle exit and hypersonic speed, which is applied in the direction of measuring devices, instruments, aerodynamic tests, etc., can solve the problems of electrical equipment safety hazards, equipment corrosion in the test section, and easy leakage of cooling water, etc., to achieve good cooling effect and avoid Local dry burning and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

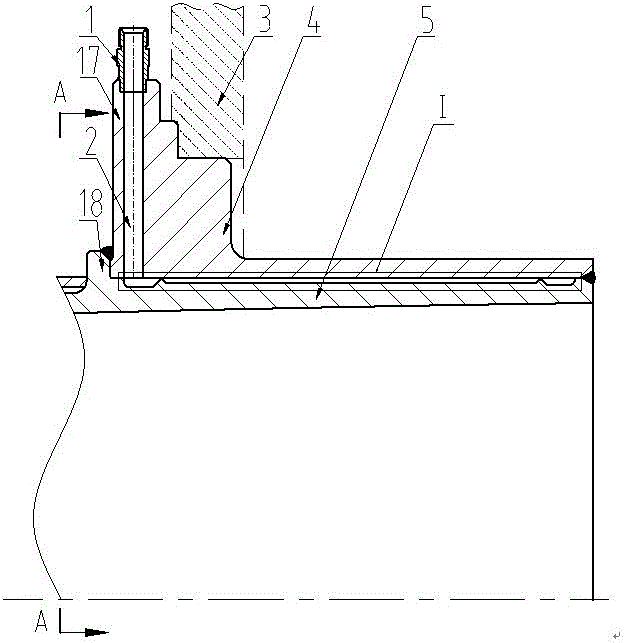

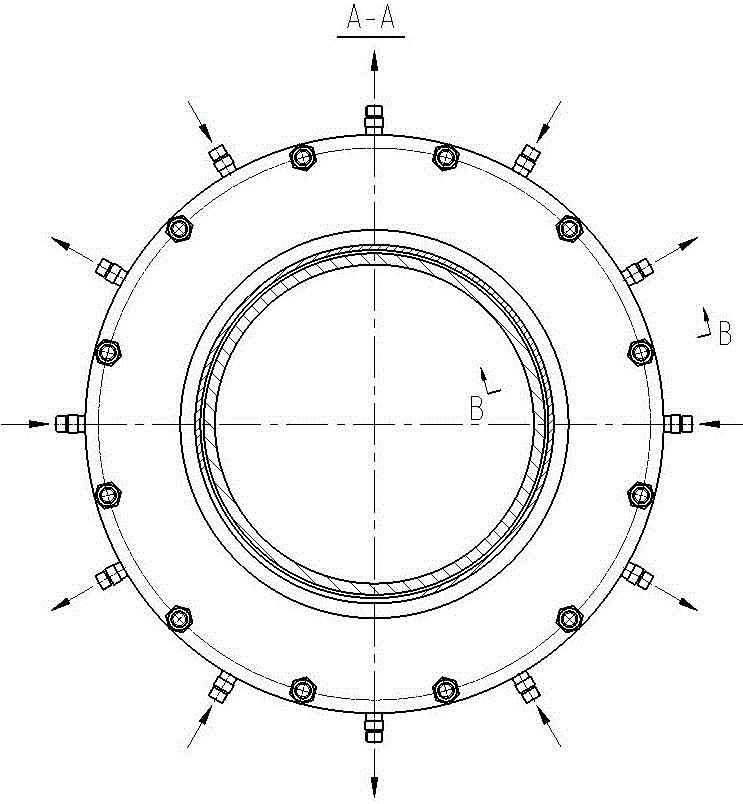

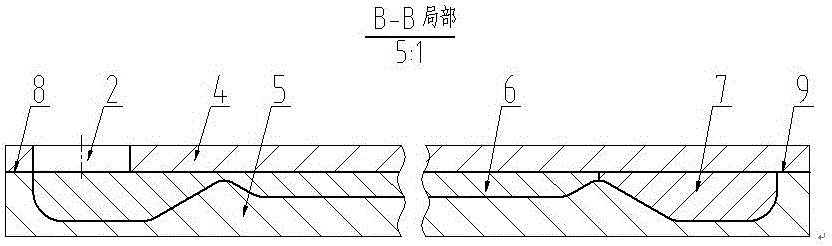

[0028] Such as figure 1 As shown, the exterior of the outer casing 4 is provided with a positioning and sealing end surface, which is docked with the entrance side wall plate 3 of the test section of the wind tunnel for positioning and sealing. The outer casing 4 is wrapped on the inner casing 5, and is sealed and connected with the annular seams on both sides of the inner casing 5 by full welding. Between the outer casing 4 and the inner casing 5 is an interlayer for the circulation of cooling water, and the interlayer is divided into two parts by the water dividing rib 6 and the blocking block 7 welded on the inner casing 5 ncooling unit. There is a flange I17 on the outer shell 4, and there is a water hole 2 along the radial direction of the flange I. The outer side of the water hole 2 is welded with a water joint 1, and the water joint 1 is connected to an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com