Method and system for testing and calibration of range extender bench of electric automobile

A technology of bench testing and electric vehicles, which is applied in vehicle testing, machine/structural component testing, instruments, etc., can solve the problems of low calibration efficiency and achieve the effect of reducing test costs and improving efficiency

Inactive Publication Date: 2016-08-24

BEIJING ELECTRIC VEHICLE

View PDF8 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the related art, the range extender of the extended-range electric vehicle needs to be calibrated to obtain the optimal operatin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

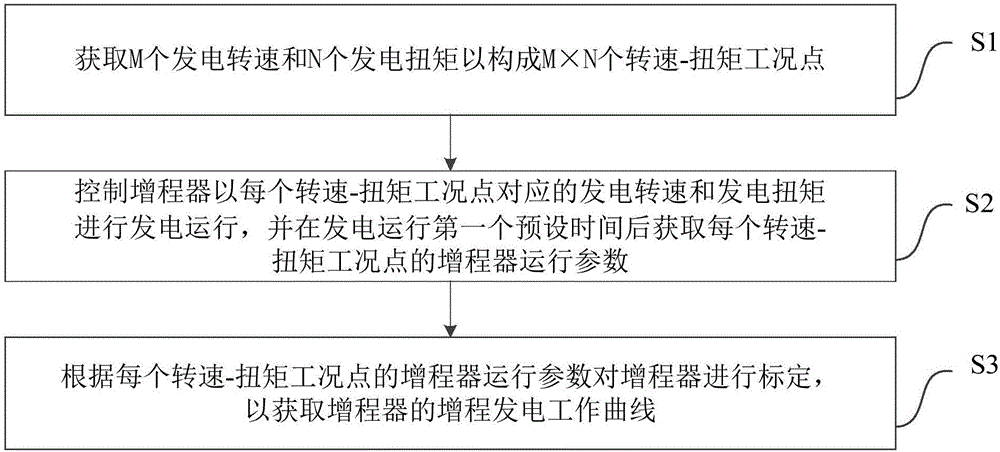

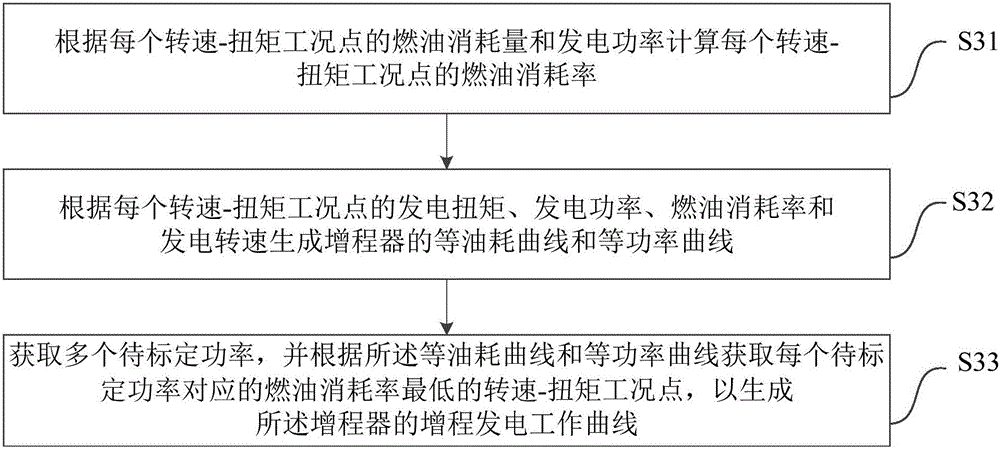

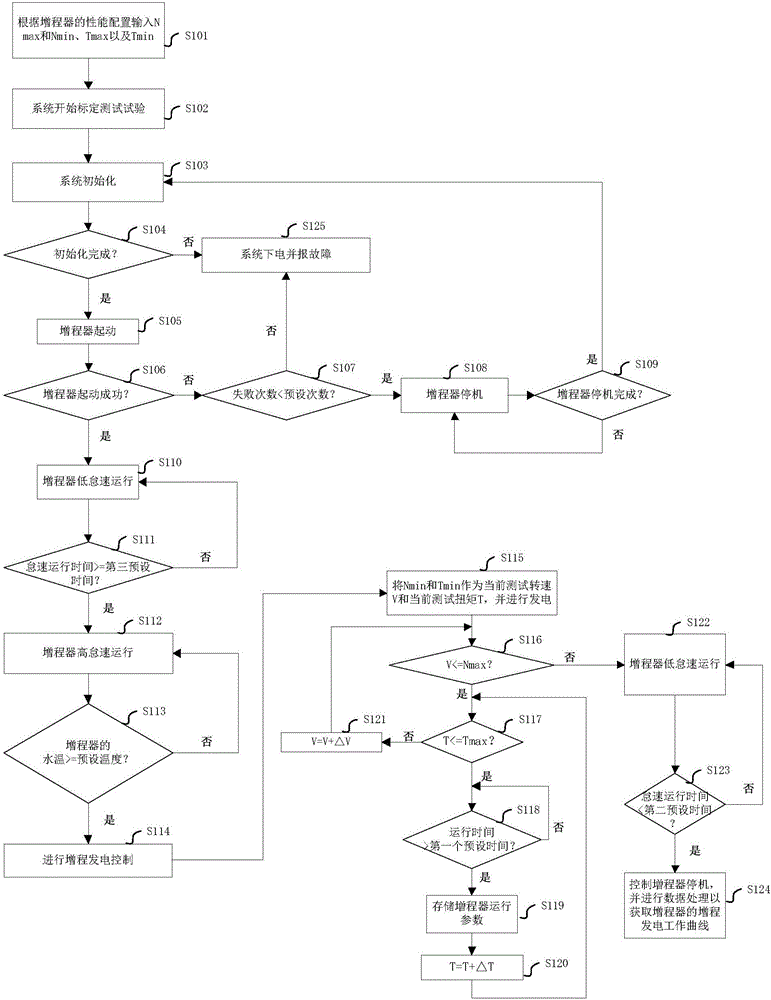

The invention discloses a method and system for testing and calibration of a range extender bench of an electric automobile. The method comprises the steps that M electricity generation rotation speeds and N electricity generation torque values are acquired to constitute M*N rotation speed-torque operating points; a range extender is controlled to carry out electricity generation operation according to an electricity generation rotation speed and an electricity generation torque value corresponding to each rotation speed-torque operating point, and operating parameters of the range extender at each rotation speed-torque operating point are obtained after a first preset time of the electricity generation operation; and according to the operating parameters of the range extender at each rotation speed-torque operating point, the range extender is calibrated, so that a range-extending electricity generation work curve of the range extender can be obtained. In this way, the rapid testing and the automatic calibration of the range extender bench can be implemented; efficiency for the testing and the calibration can be effectively increased; and the testing cost can be reduced.

Description

technical field [0001] The invention relates to the technical field of electric vehicles, in particular to a test and calibration method for a range extender bench for electric vehicles and a test and calibration system for a range extender bench for electric vehicles. Background technique [0002] Range-extended electric vehicles are one of the most promising products for industrialization. Compared with other hybrid vehicles, range-extended electric vehicles have a simple configuration system, more reliable performance and less cost; compared with pure electric vehicles, extended-range electric vehicles Program electric vehicles have longer driving range and lower cost. [0003] In the related art, the range extender of the extended-range electric vehicle needs to be calibrated to obtain the optimal operating point. However, the disadvantage of the related technology is that manual calibration is required, and the calibration efficiency is low. Contents of the invention ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M17/007

CPCG01M17/007

Inventor 崔天祥易迪华王金龙金硕李从心周金龙秦兴权魏跃远

Owner BEIJING ELECTRIC VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com