Method for evaluating reliability of shot blasting part with X-ray diffraction technology

A technology for parts and reliability, applied in the field of parts inspection, can solve problems such as difficulty in predicting the reliability of key parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is realized through the following technical solutions, and concrete steps, work process and principle are as follows:

[0018] 1. Establish the change law of residual stress and diffraction full width at half maximum of a certain component material under external load:

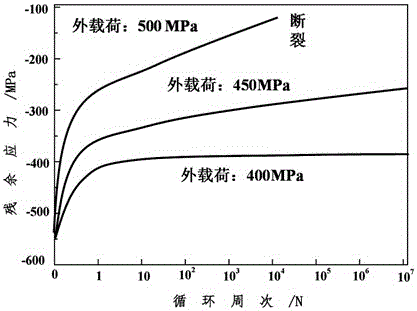

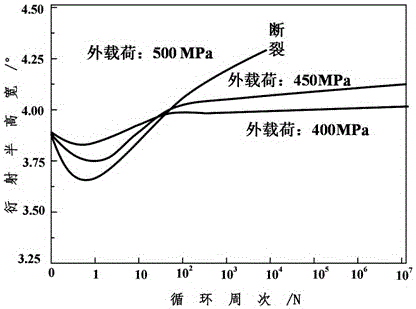

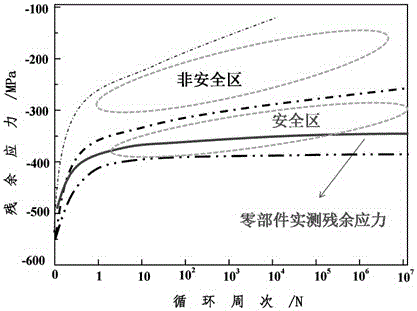

[0019] Determine the material phase, and select a suitable diffraction peak with a high diffraction angle as the residual stress measurement peak. Using the X-ray diffraction stress analysis method, select different external loads, and measure the residual stress relaxation law and the change law of the half-height width of the diffraction peak under different external loads under the action of the stressed operation cycle, that is, when the external load is set Under the action of load, the X-ray diffraction equipment is used to detect and analyze the stress of the parts during the working and operation of the parts and materials, and the law of the residual stress relaxation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com