Calibration method for micromagnetic detection of ferromagnetic material structural mechanics performance

A technology of ferromagnetic materials and calibration methods, which is applied in the direction of material magnetic variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

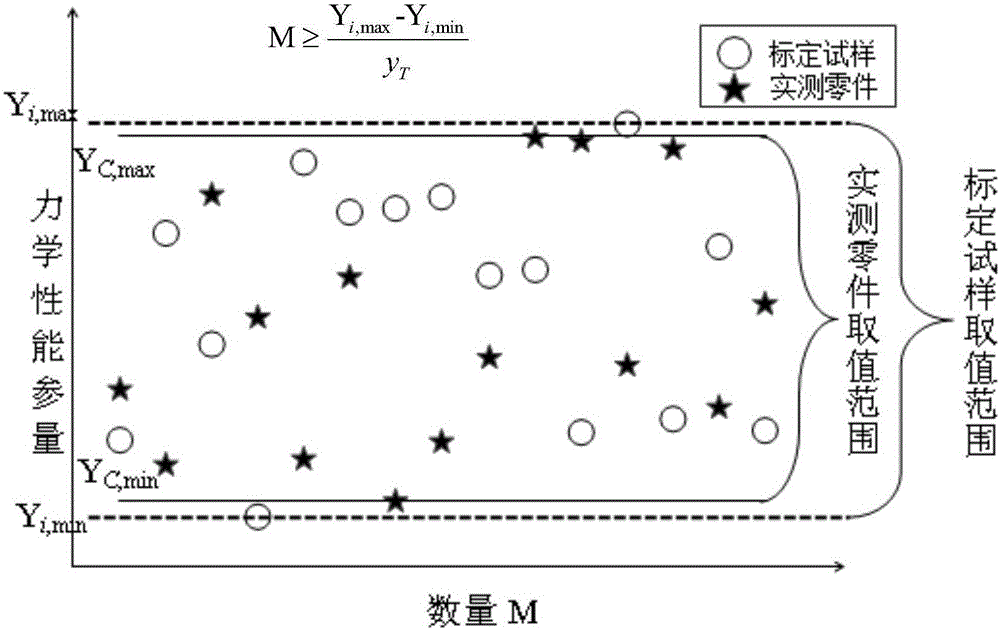

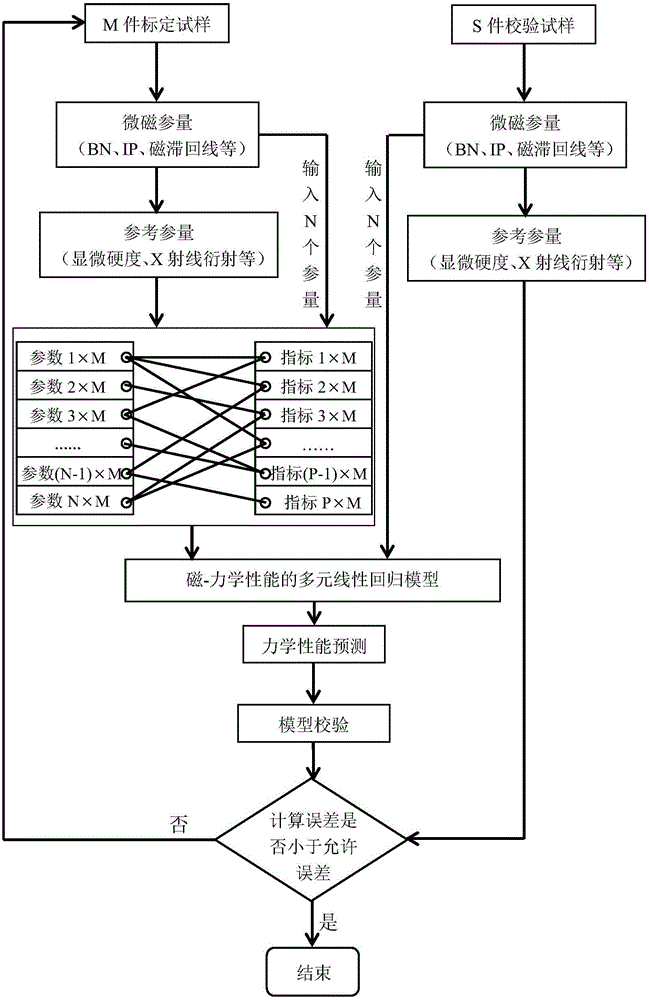

[0025] Such as figure 1 As shown, firstly, select the calibration sample and the check sample, which can be randomly selected from the production line and the rejected parts library.

[0026] Secondly, after the micro-magnetic measurement of the calibration sample is carried out and the micro-magnetic parameter data set is extracted, the mechanical properties of the calibration sample are tested using the conventional mechanical property test method recommended by the national standard.

[0027] Thirdly, the multiple linear regression method was used to analyze the micromagnetic parameter data set and the mechanical performance parameter data set, and a multiple linear regression model of the magnetic-mechanical performance was obtained in which the mechanical performance parameter was the dependent variable and multiple micromagnetic parameters were the independent variables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com