Automatic ultrasonic scanning method and device for die steel

A die steel, automatic technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc., can solve the problems of low detection efficiency, low detection accuracy, backwardness, etc. The effect of optimizing recycling, scientific and reasonable processing, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

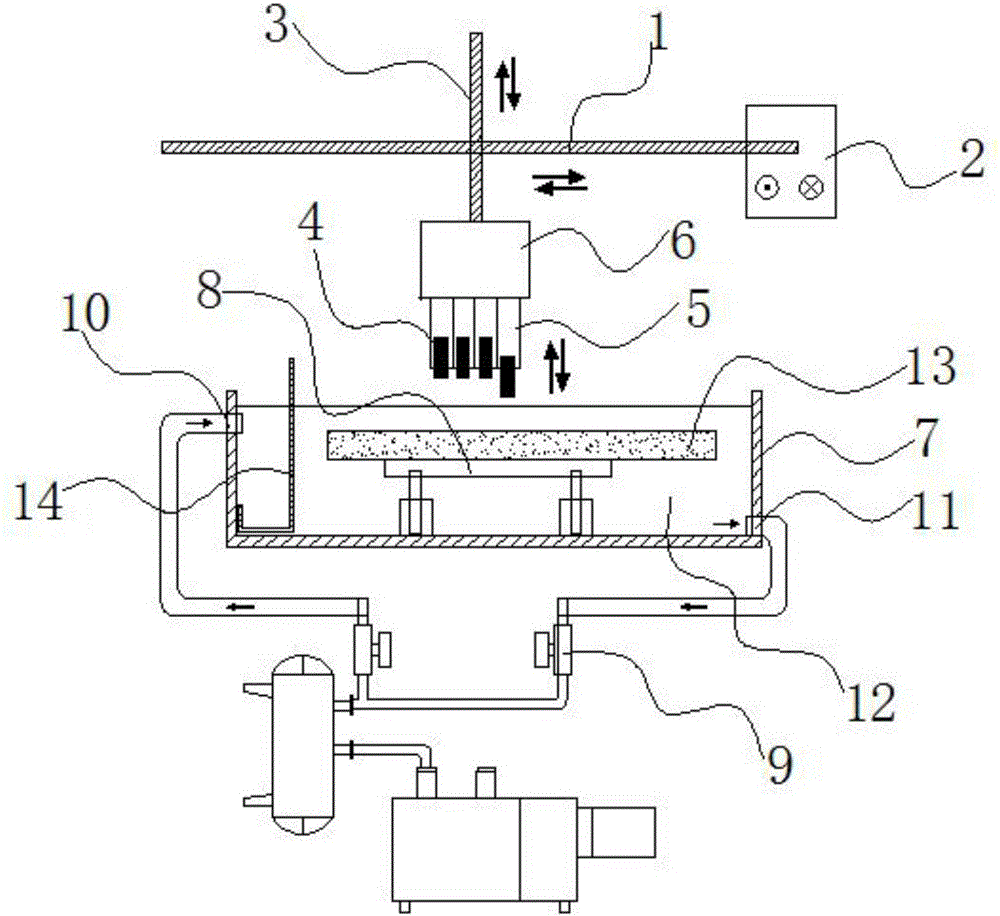

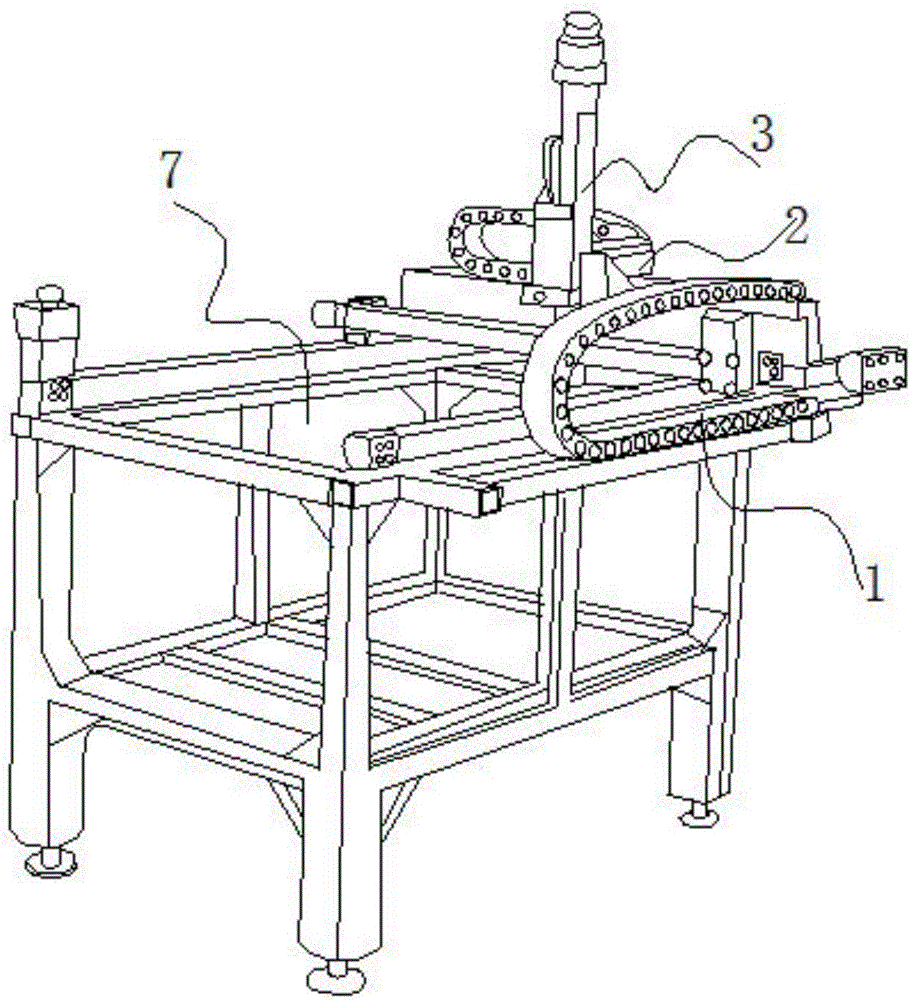

[0023] see Figures 1 to 2 , the mold steel automatic ultrasonic scanning method provided in this embodiment includes the following steps:

[0024] 1) Set up a manipulator mechanism, the manipulator mechanism includes X-axis moving component 1, Y-axis moving component 2 and Z-axis moving component 3; set up an ultrasonic scanning mechanism, the ultrasonic scanning mechanism includes ultrasonic probe 4, probe telescopic cylinder 5 and the probe holder 6; a working tank mechanism is provided, the working tank mechanism includes a tank body 7 for accommodating couplant, a carrier platform 8 located in the middle of the tank body 7 and a coupling agent circulation assembly 9 connected with the tank body 7, The couplant circulation assembly 9 includes a pipeline and a hydraulic device, and the pipeline is respectively connected with the liquid inlet 10, the liquid outlet 11 and the hydraulic device of the tank body, so as to realize the control and recycling of the couplant 12; A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com