Zero-crossing trigger control circuit for anti-parallel thyristor split-phase switched capacitor

A zero-crossing trigger and control circuit technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems of non-zero-crossing triggering of thyristors, unreasonable trigger pulses, damage to thyristor modules, etc., and achieve stable operation Reliable, avoid overvoltage breakdown of isolation devices, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

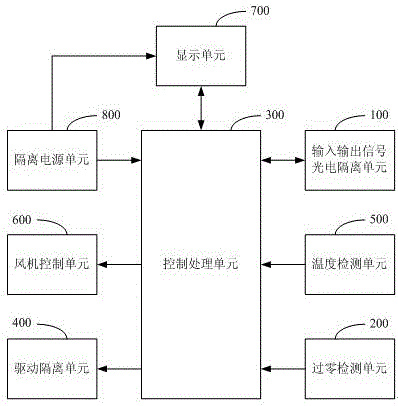

[0057] see figure 1 , in one embodiment, the zero-crossing trigger control circuit of the anti-parallel thyristor split-phase switching capacitor may include: an input and output signal photoelectric isolation unit 100 , a control processing unit 300 , a zero-crossing detection unit 200 and a drive isolation unit 400 . Wherein, the control processing unit 300 is respectively connected with the input and output signal photoelectric isolation unit 100 , the zero-crossing detection unit 200 and the driving isolation unit 400 . The input and output signal photoelectric isolation unit 100 is configured to generate a low-level control signal according to an external control signal and send it to the control processing unit 300 . The zero-crossing detection unit 200 is used to detect whether the voltages at both ends of the thyristor are eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com