Disc-type coreless permanent magnet motor employing modular PCB stator

A technology of application modules and permanent magnet motors, applied in the shape/style/structure of winding conductors, static components of magnetic circuits, shape/style/structure of magnetic circuits, etc., can solve eddy current loss, cogging torque fluctuation, automation Problems such as complex off-line process and inconvenient mass production achieve compact axial space, simplify armature manufacturing process and printed circuit board assembly process, and enhance manufacturing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

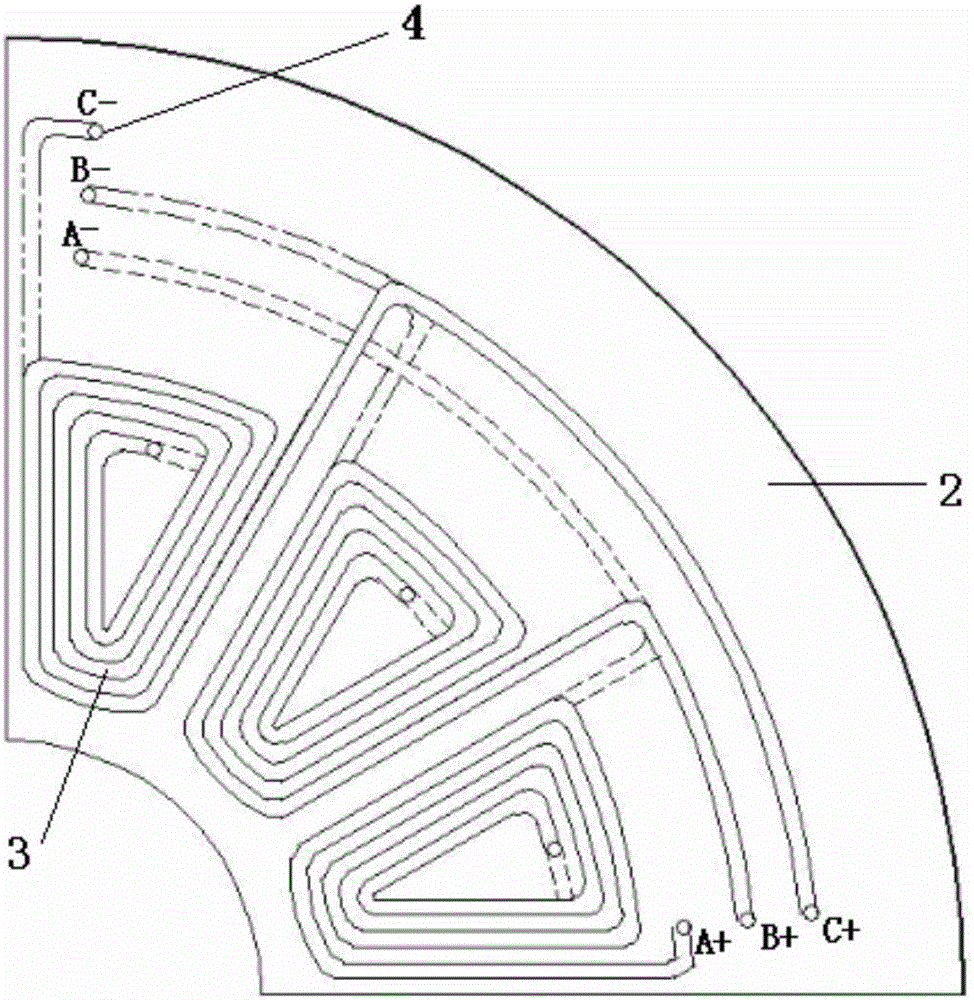

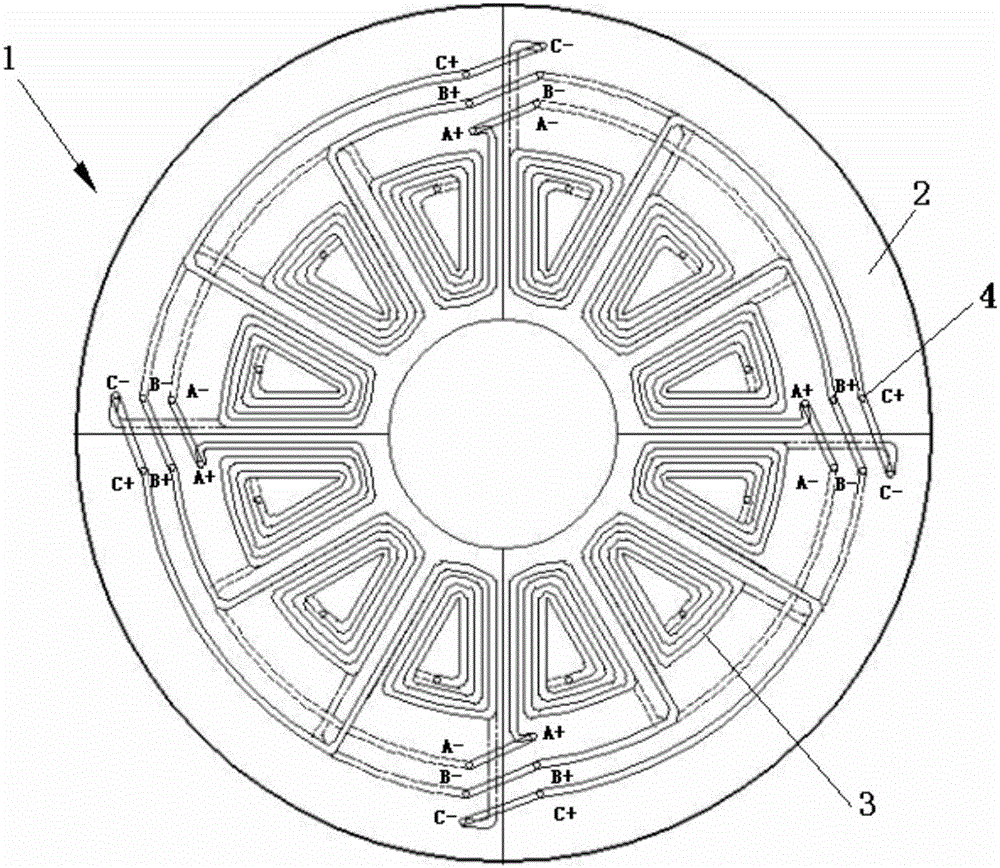

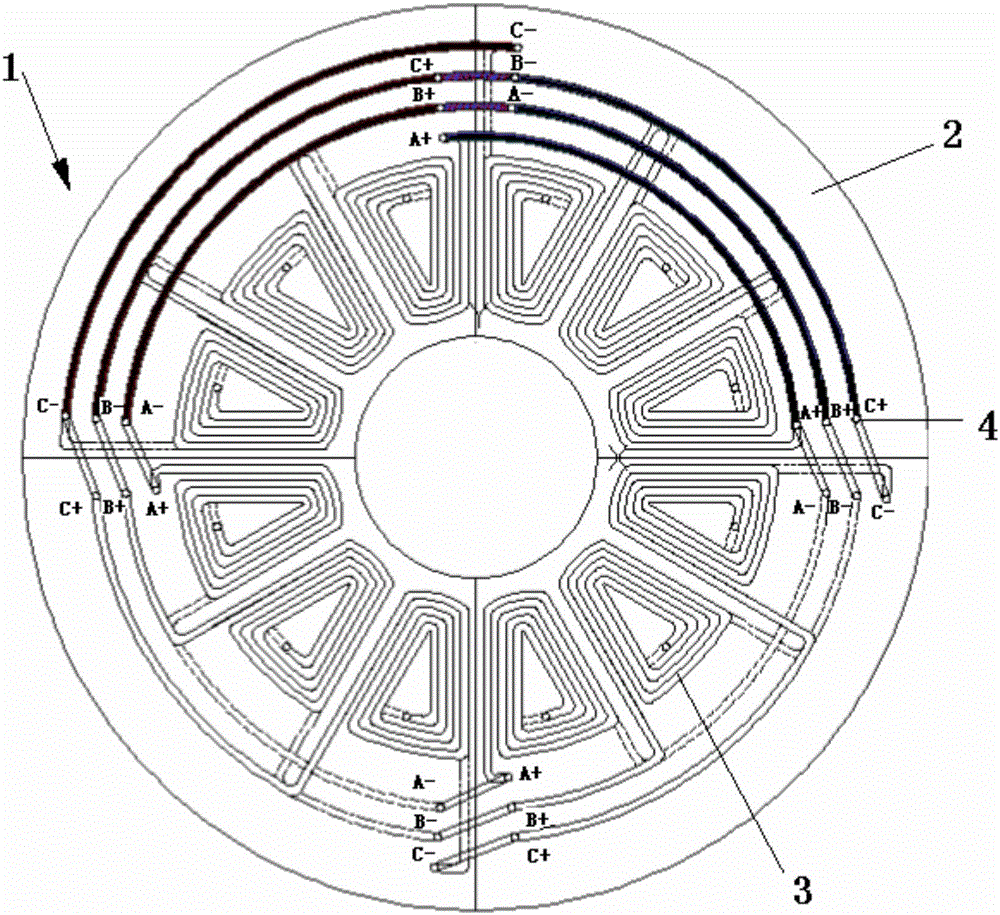

[0025] The present invention has a single-stator double-rotor structure. The rotor part includes a back iron support and a surface-mounted NdFeB permanent magnet. The stator is composed of several identical circular PCB circuit boards 1 stacked, and the outside can be pressed by an end cover. The thickness is fixed with screws, and the PCB circuit board 1 is divided into four 90° fan-shaped ring modules 2. The axial connection between each module 2 is realized by setting multiple holes at the inner or outer diameter of each module 2. like figure 1 As shown, each module 2 is uniformly printed with three winding coils 3 along the circumferential direction, and the winding coils 3 are set in a spiral shape, and six outlet holes for positive and negative three-phase are respectively set, such as A + , B + 、C + and A - , B - 、C - The three conductive connection holes 4 of the positive electrode are radially arranged along a diameter side of the module 2, so as to facilitate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com