Climbing plant cultivation frame

A cultivation rack and planting rack technology, applied in the field of plant cultivation, can solve the problems of low land use efficiency, large occupied area, and poor cultivation effect, and achieve the effects of improving land utilization rate, long service life, and good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

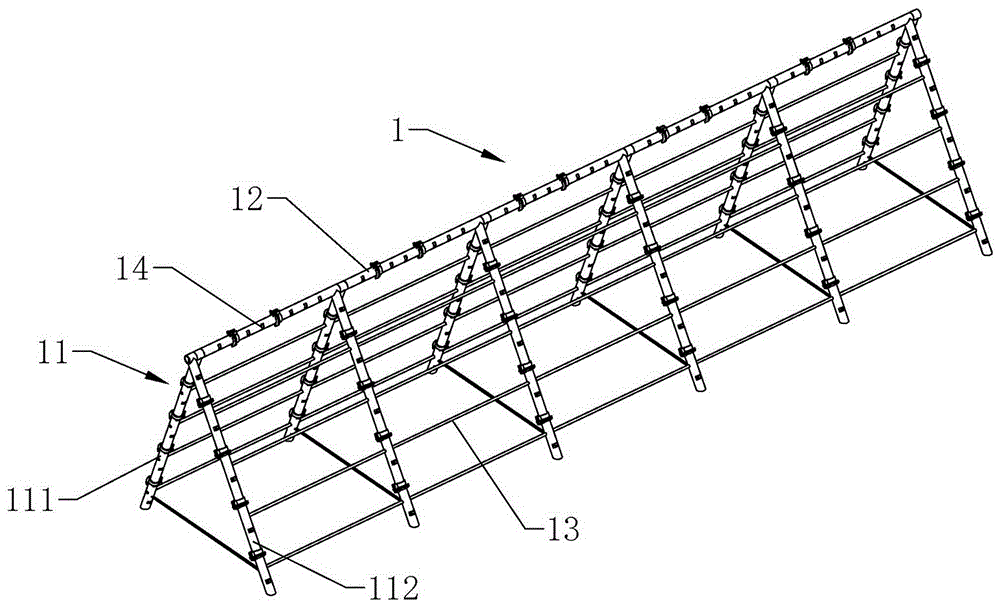

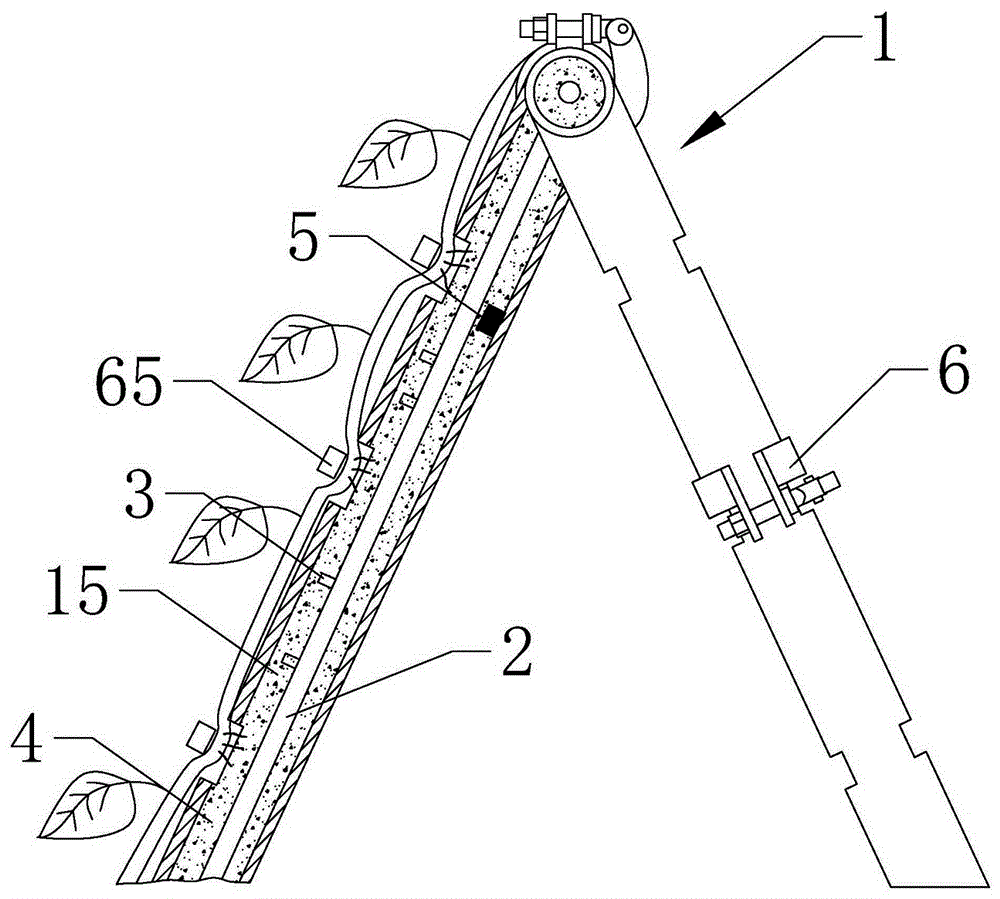

[0023] according to figure 1 , figure 2 , image 3 , Figure 5 As shown, a vine plant cultivation frame includes a planting frame 1 and a water delivery pipe 2 in the planting frame 1, and the planting frame includes: several inverted "V"-shaped support units 11, connecting rods that connect the support units 11 in a row 12 and connecting bar 13, the bracket unit 11 includes a first bracket 111 and a second bracket 112, the bracket unit 11 is connected to the connecting rod 12 through the top of the first bracket 111 and the second bracket 112, and the connecting bar 13 is arranged below the connecting rod 12 And parallel to the connecting rod 12, the top of the first bracket 111 is hingedly connected with the connecting rod 12; the first bracket 111, the second bracket 112 and the connecting rod 12 are all hollow tubes, and the tube wall is provided with a through hole 14; The water delivery pipe 2 is arranged on the inside of the first support 111, the second support 112...

Embodiment 2

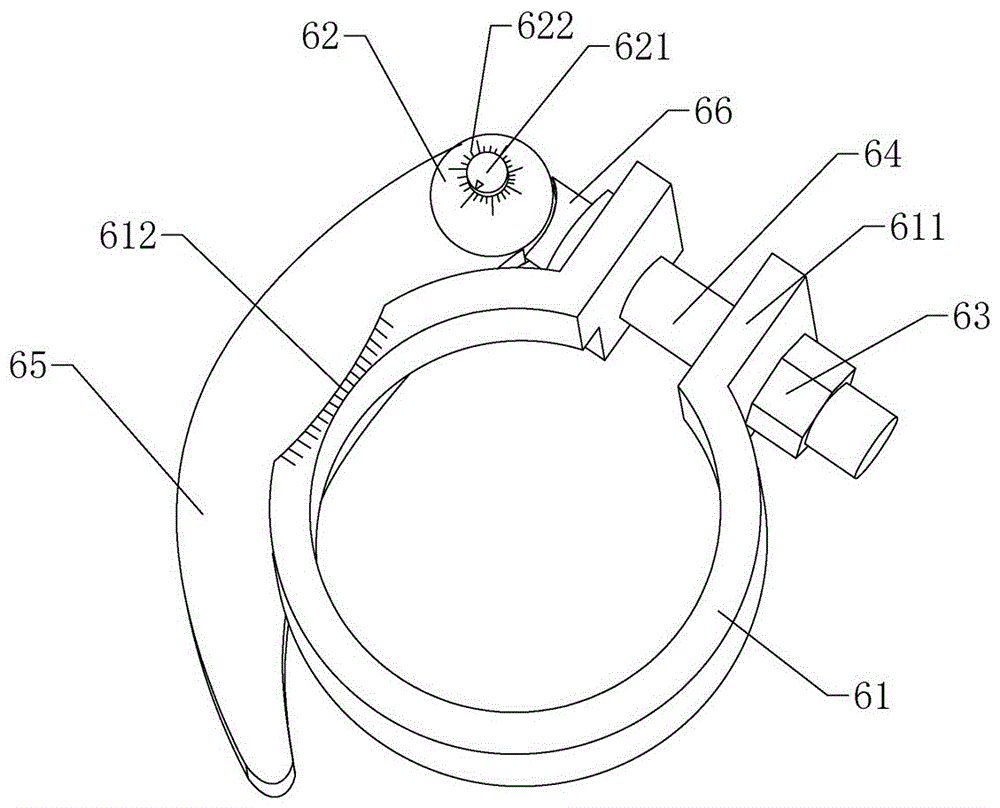

[0027] The difference from the above-mentioned embodiment 1 is that, according to image 3 As shown, the pressure vine buckle 6 includes a clamp ring 61, an eccentric wheel 62, a bolt 63 and a nut 64, the clamp ring 61 is an annular hoop with an opening, the two ends of the opening are provided with a fixing seat 611, and the bolt 63 is inserted in the fixing seat 611 and the two ends of bolt 63 are respectively connected with eccentric wheel 62 and nut 64, eccentric wheel 62 is hinged with bolt 63 through eccentric wheel shaft 621, and eccentric wheel 62 is provided with pressing bar 65 for pressing vine, eccentric wheel 62 and fixed seat 611 U-shaped pads 66 are provided therebetween. Through the cooperation of the eccentric wheel 62, the bolt 63 and the nut 64, the tightness of the clamp ring 61 can be adjusted, thereby adjusting the fixed position of the pressure vine buckle 6 on the planting frame, and the pressure rod 65 is connected with the eccentric wheel 62. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com