Spline shaft and manufacturing method thereof

A manufacturing method and spline shaft technology, which can be used in other household appliances, coupling devices, applications, etc., and can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be analyzed and described with reference to the drawings.

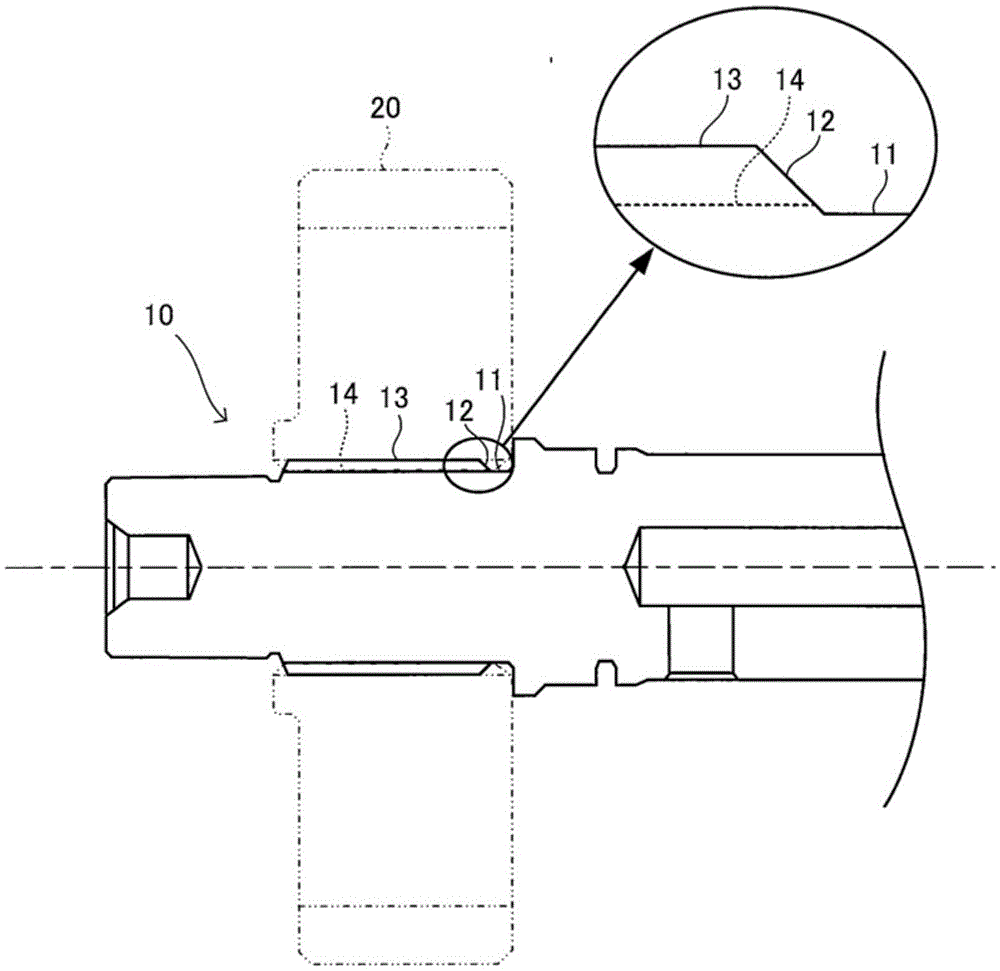

[0030] figure 1 A spline shaft 10 according to an embodiment of the present invention is shown. The spline shaft 10 is a different-diameter shaft having a plurality of portions with different diameters. In this example, the spline shaft 10 has a small-diameter portion 11 and a large-diameter portion 13 connected to the small-diameter portion 11 via a tapered portion 12 and having a larger diameter than the small-diameter portion 11, and the large-diameter portion 13 is formed by roll forming. keyway 14. The gear 20 having teeth corresponding to the spline grooves 14 on the inner periphery is spline-fitted to the large-diameter portion 13 , whereby rotation can be transmitted from the spline shaft 10 to the gear 20 .

[0031] The roll forming is performed by pressing a pair of roll formed racks having teeth corresponding to the spline grooves 14 against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com