Mica powder unloading hopper with reverse sucking cover

A reverse suction hood and mica powder technology, applied in the field of mica powder processing, can solve the problems of affecting the grading effect and unstable feeding, and achieve the effects of improving the grading effect, uniform feeding and working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

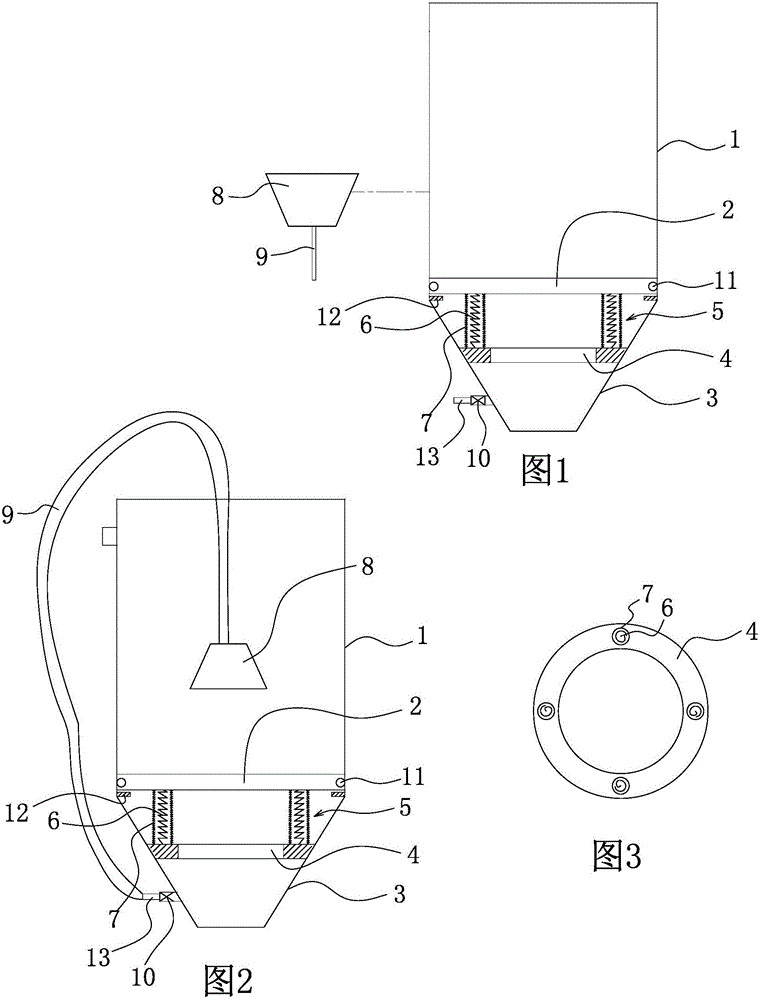

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] like figure 1 As shown, a mica powder lowering hopper with a suction cover includes a cylindrical hopper 1, the top and bottom of the hopper 1 are respectively open, and the mica powder is input from the top of the hopper 1, and the hopper is 1 is provided with a blanking plate 2 that is movably connected to the inner wall of the hopper 1. The blanking plate 2 is densely covered with blanking holes. Adjustment, the bottom of the hopper 1 is also connected with a collection bucket 3 in the shape of an inverted frustum cone, and a ring-shaped support plate 4 is fixed in the collection bucket 3, and the middle of the support plate 4 is circular. Cavity, mica powder is blanked from the cavity, and an elastic deformable elastic member 5 is provided on the support plate 4, and the two ends of the elastic member 5 are fixedly connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap