Automatic overturning and feeding device of copper bars

A technology of automatic turning and feeding device, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of poor safety, low degree of automation, low efficiency, etc., and achieve production safety and yield improvement. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

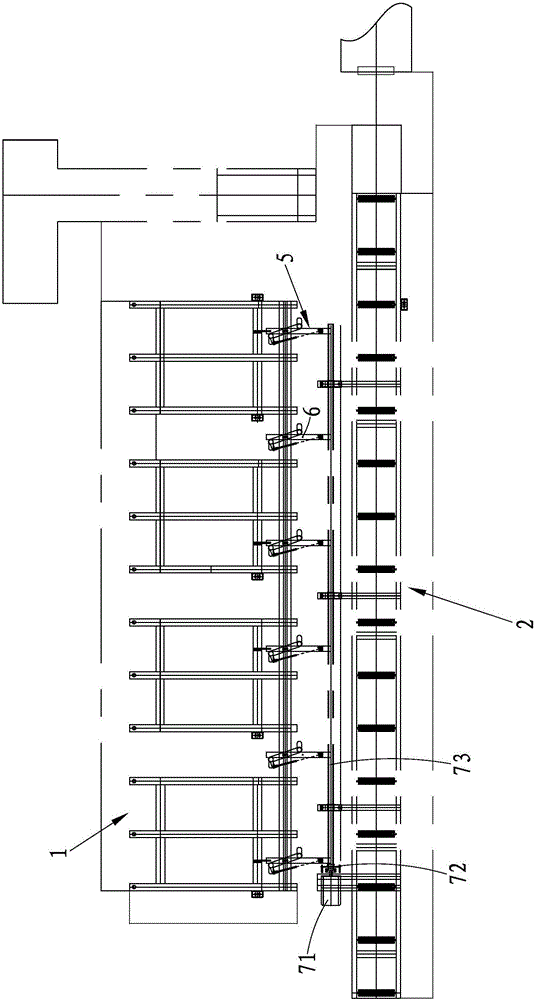

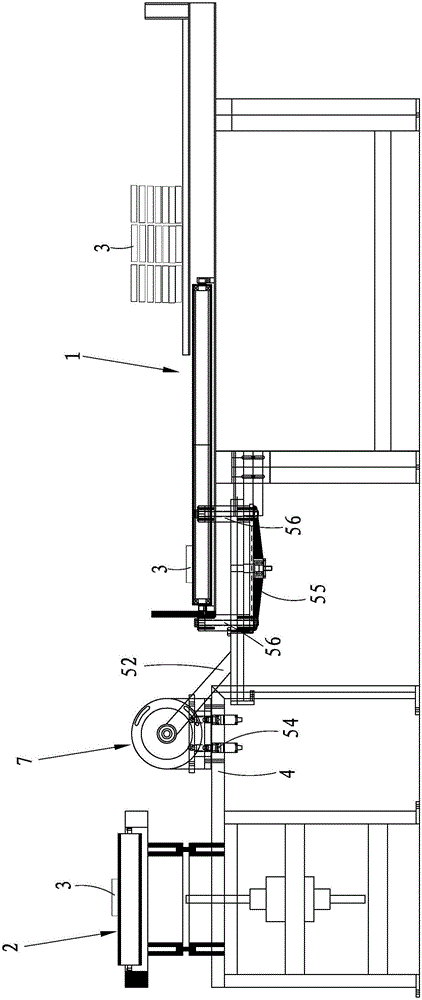

[0022] as attached 1 and 2 As shown, a copper bar automatic flip feeding device, the copper bar automatic flip feeding device is set on the storage platform 1 Loading platform with drawing machine 2 Between, loading platform 2 The height is higher than the storage platform 1 , in this embodiment, the storage platform 1 Connected with the rolling head machine, the copper bar after coming out of the rolling head machine 3 The first drive assembly stacked on the storage platform 7 , driven by the first component 7 Drive rotation so that the storage platform 1 copper bar 3 Turn over and transport to the loading platform 2 transport agency on 5 , transport agency 5 There are multiple and along the loading platform 2 The distribution in the length direction can better hold the copper bar 3 。

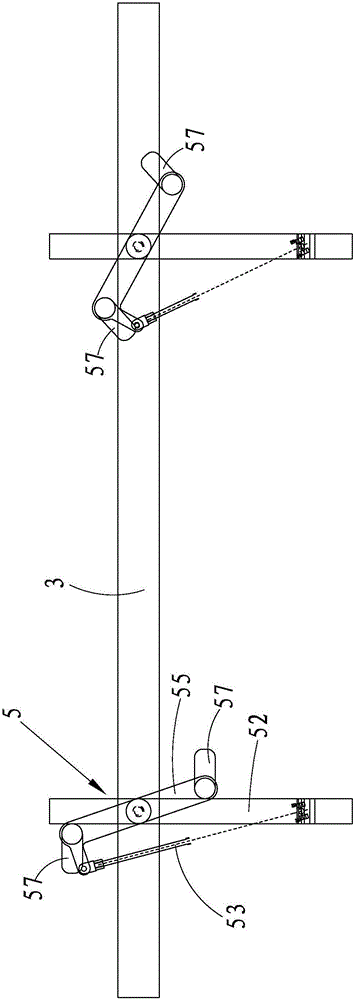

[0023] transportation agency 5 Included is a drive assembly consisting of a first 7 swivel arm 52 , with the swivel arm 52 Phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com