Method of treating emulsified steam turbine oil

A technology of turbine oil and treatment method, applied in the direction of magnetism of organic material/organic magnetic material, lubricating composition, etc., can solve problems such as the decline of anti-emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention are described below. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0039] In order to further illustrate the essence of the present invention, the following experimental analysis was carried out using the method of the present invention.

[0040] 1. Magnetic demulsifier Fe 3 o 4 -EC performance test analysis

[0041] 1. Magnetic properties

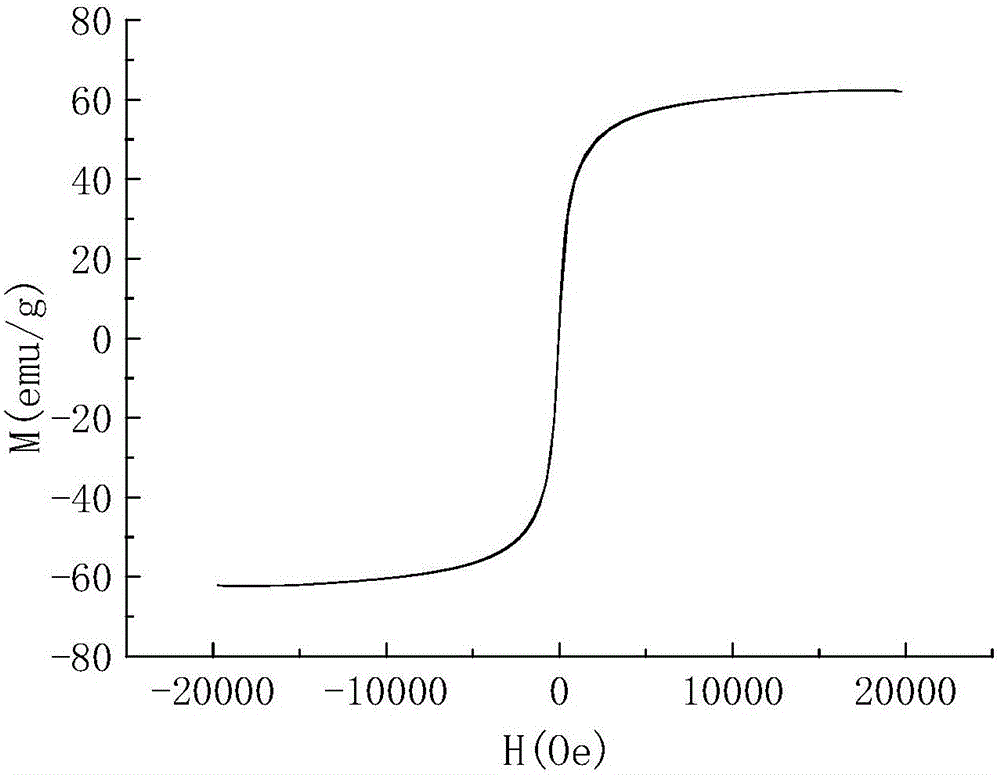

[0042] Hysteresis loop of magnetic demulsifier see figure 1 ,Depend on figure 1 Available, demulsifier Fe 3 o 4 The magnetization saturation intensity of -EC is 62emu / g, that is, the magnetism is strong; the coercive force is zero, indicating the superparamagnetism of the magnetic demulsifier particles.

[0043] 2. Comparative detection of hydrophilicity and lipophilicity

[0044] Fe3O4, ethyl cellulose and magnetic demulsifier Fe 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com