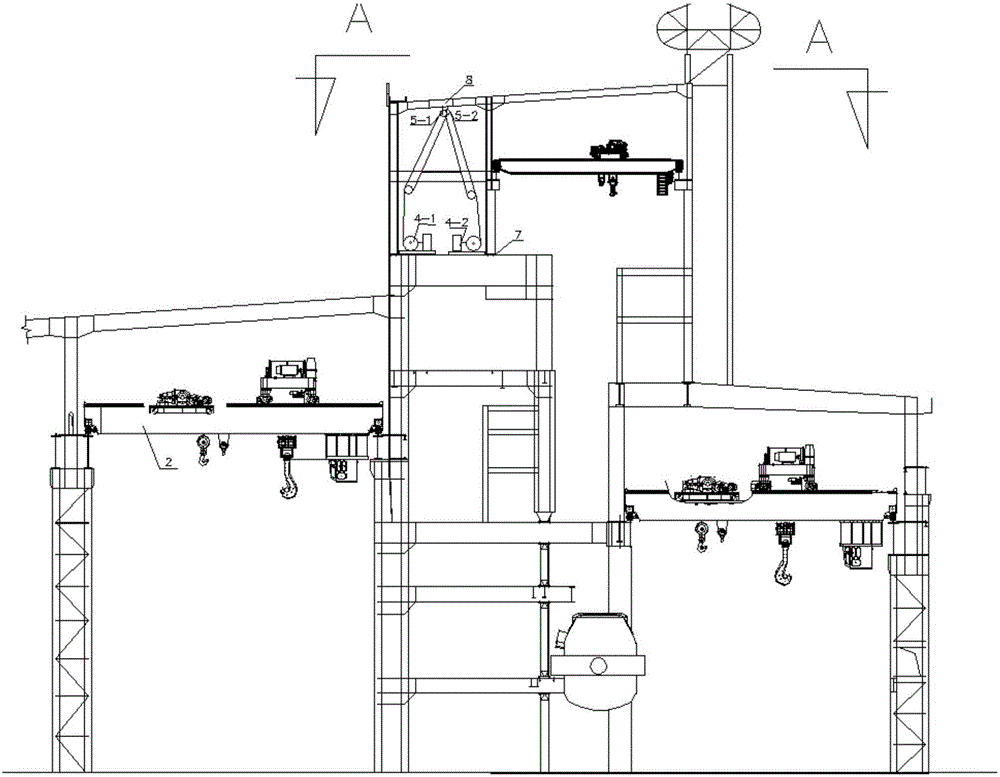

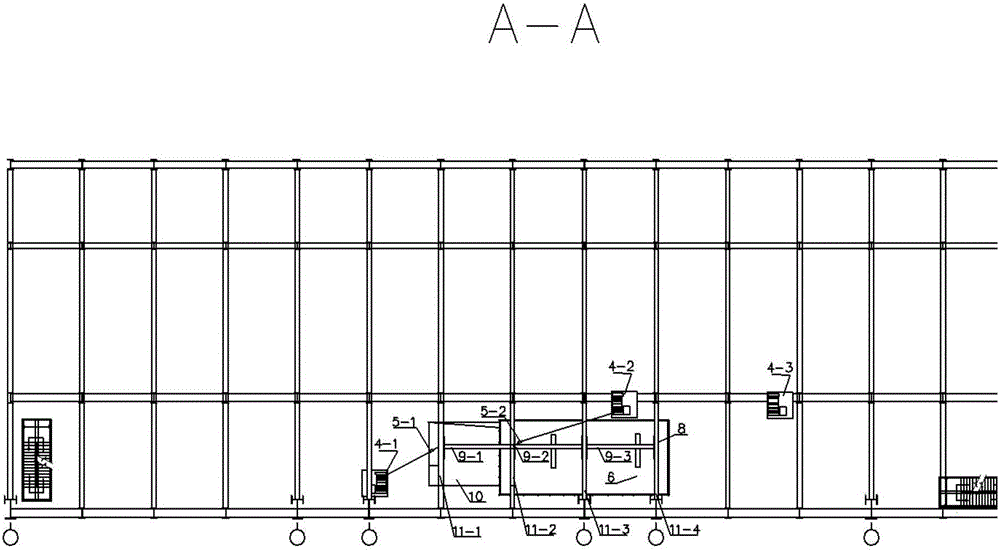

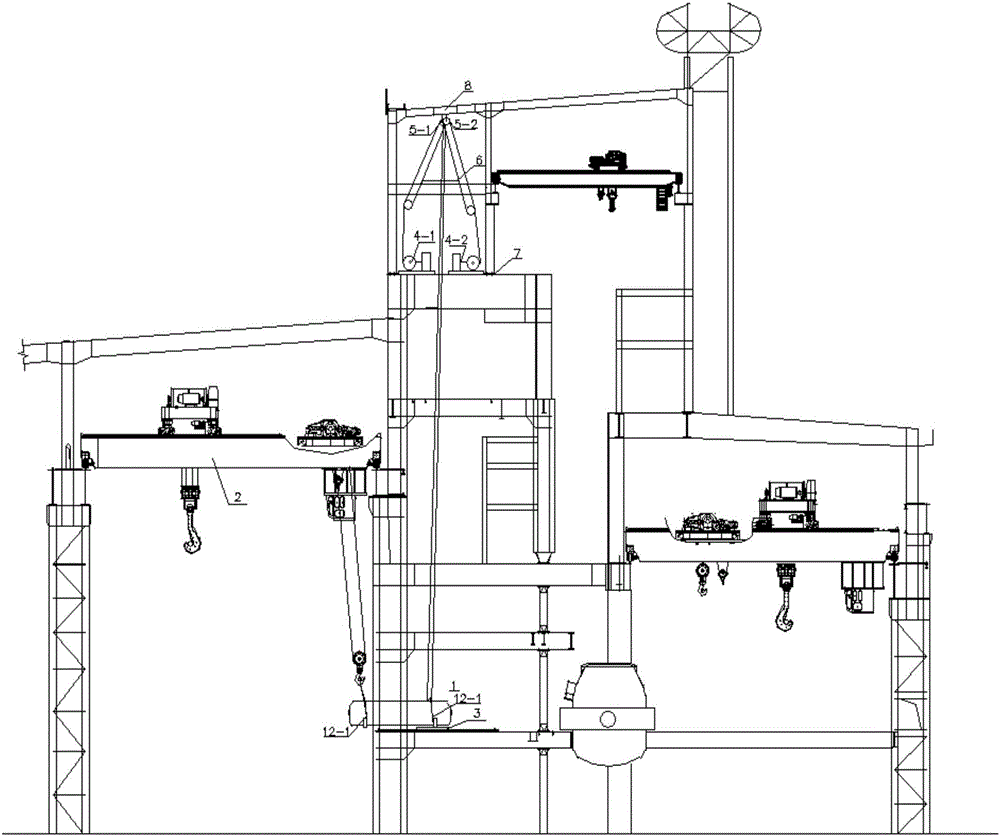

Method for converter steam drum emplacement after workshop closing

A technology for steam drums and workshops, applied in the manufacture of converters, etc., can solve problems affecting production line production, long construction period, and increased project investment costs, and achieve the effects of reducing project cost investment, ensuring progress, and improving overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Such as Figure 1-8 As shown, the pipe belt machine threading and pulling device of the present invention comprises a belt 1 after cutting, a splint 2, a connecting bolt 3, and a shackle hole 4; Waist trapezoidal shape to ensure the smooth introduction of the cut belt 1 into the tubular entrance section; the cut belt 1 is connected with the shackle hole 4 through the splint 2, and the cut belt 1 is formed by the formal belt according to the isosceles Trapezoidal cutting, the width of the upper opening after cutting is greater than the width of the splint 2, and the size is 400mm. The splint 2 is composed of two upper and lower splints 2 with a thickness of 16-20mm, which is in the shape of a trapezoidal arc. The connection method adopts six groups of bolts of M20, and the hole diameter The connection to the shackle is aperture.

[0035] Specifically: such as figure 1 , figure 2 Shown, step 1 structural reinforcement

[0036] 1. According to the tower roof beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com