Textile material and preparation method thereof

A technology of textile materials and yarns, applied in the field of textile materials and their preparation, to achieve the effect of comfortable wearing and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

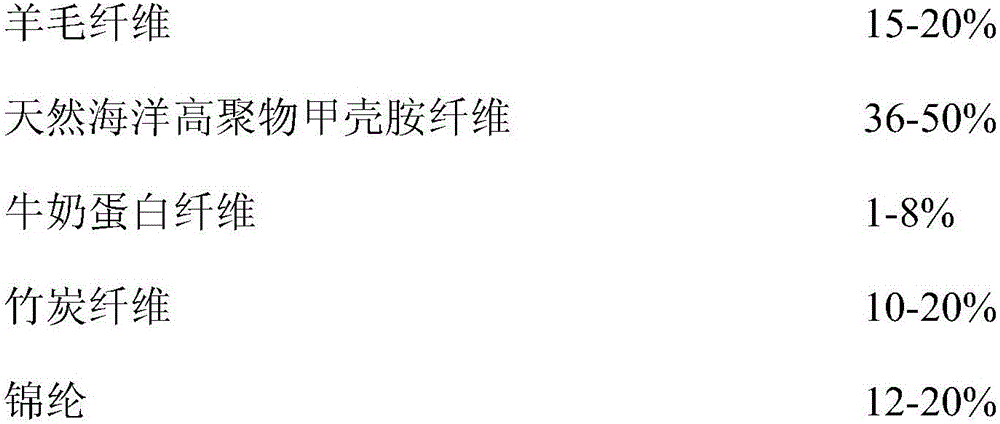

[0028] In this example, the textile material was prepared by blending raw materials in the following weight percentages:

[0029]

[0030] The preparation process is as follows:

[0031] The wool fiber is blended with the natural marine high polymer chitosan fiber, and then blended with nylon to obtain the textile material.

[0032] Wherein said blending process:

[0033] 1. Wool fiber, bamboo charcoal fiber, milk protein fiber, natural marine high polymer chitosan fiber → mixed according to a certain ratio → opened and cleaned cotton to make rolls → carding machine mixed to make sliver;

[0034] 2. Nylon → open and clean cotton to make rolls → card cotton to make strips → rolls to rolls → make strips;

[0035] 3. Wool fiber, bamboo charcoal fiber, milk protein fiber, natural marine polymer chitosan fiber, nylon→draw frame→draw frame→roving frame→spinning frame→winder→finished yarn~inspection and storage.

[0036] Wherein the processing condition of the cleaning process ...

Embodiment 2

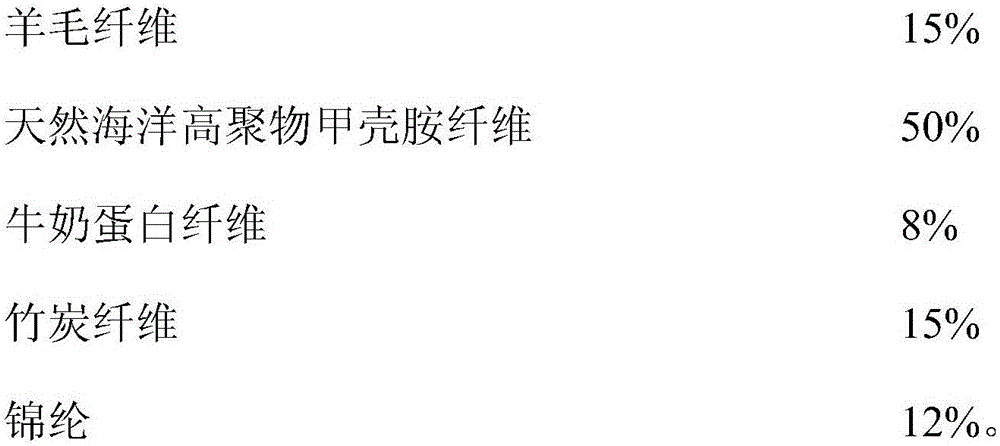

[0045] What this embodiment is different from embodiment 1 is that the raw material formula of textile material is as follows:

[0046]

[0047] Except that, all the other conditions and steps are the same as in Example 1.

Embodiment 3

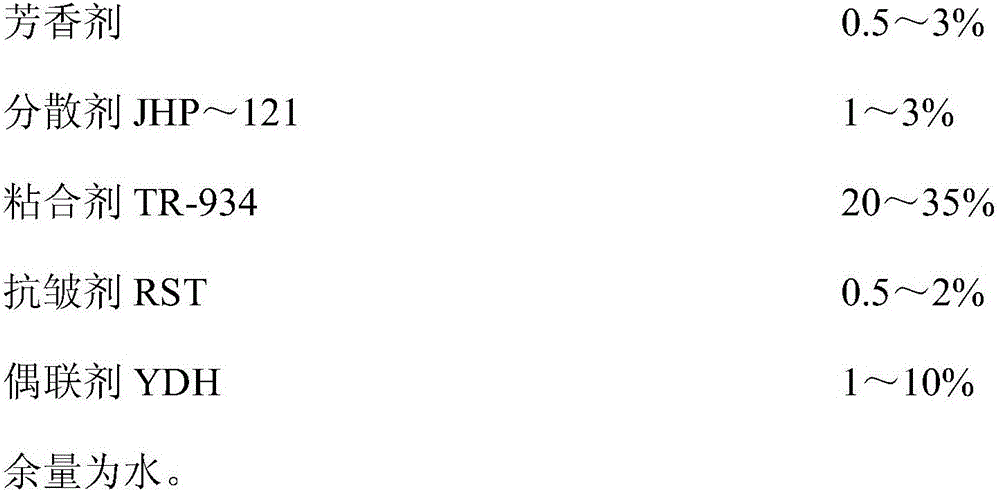

[0049] What this embodiment is different from embodiment 1 is that the raw material formula of textile material is as follows:

[0050]

[0051]

[0052] Except that, all the other conditions and steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com