Art paper with surface microstructures and preparation technology thereof

A technology of art paper and microstructure, applied in the field of art paper and its preparation technology, can solve problems such as affecting the overall quality of paintings and discarding the painting paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

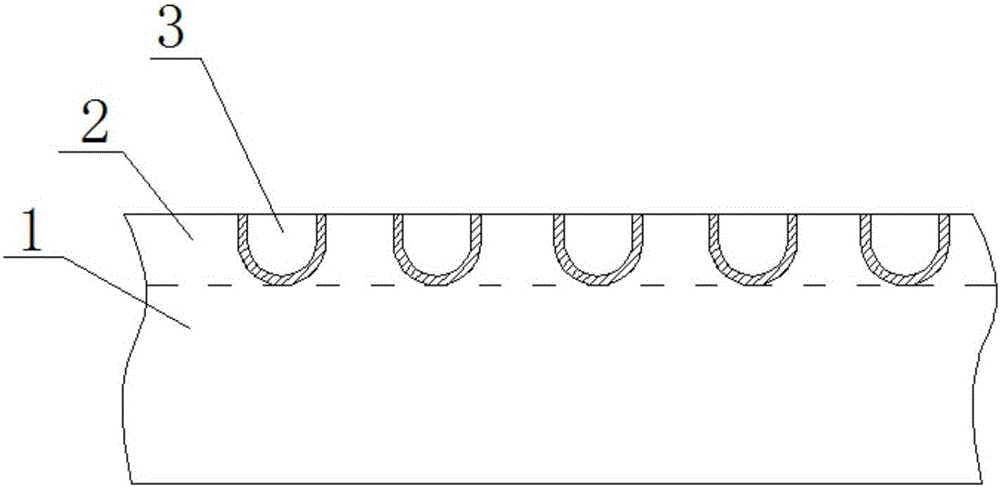

[0027] A method for preparing art paper with a microstructure on the surface, the method comprising the following steps:

[0028] Step 1: uniformly mixing the fibrous materials used for making paper, said fibrous materials comprising: 30-40 parts of wood pulp fibers, 5-15 parts of straw pulp fibers, 25-30 parts of bamboo pulp fibers, 5-15 parts of fiber cotton, Viscose fiber 10~25 parts;

[0029] Step 2: Stir the mixed fiber material in step 1 with water at a stirring rate of 40-200r / min, and stir into a uniform slurry;

[0030] Step 3: Add auxiliary agents to the homogeneous slurry in step 2 and stir evenly for later use. The auxiliary agents include: 6-8 parts of whitening agent, 3-4 parts of preservative;

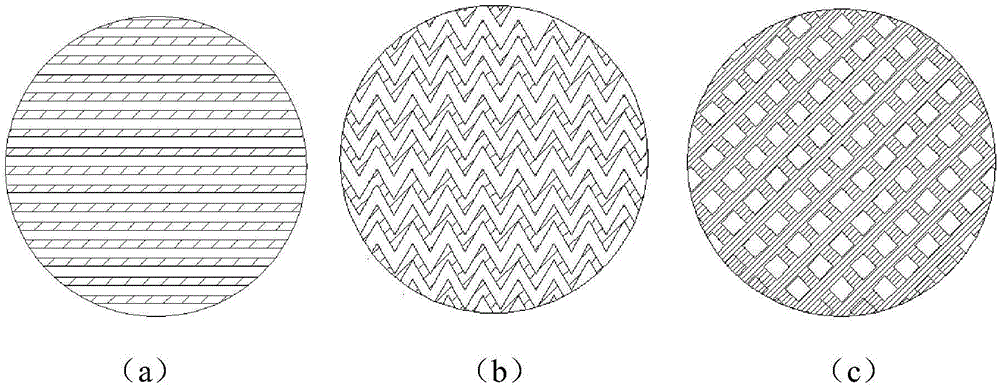

[0031] Step 4: Making the metal wires for textiles into linear, zigzag or mesh structures arranged at equal intervals and fixing the metal wire structure formed by them around, the diameter of the metal wires for textiles is less than 40um;

[0032] Step 5: soak the wi...

Embodiment 1

[0036] Step 1: uniformly mix the fiber materials used for making paper, the fiber materials include: 30 parts of wood pulp fibers, 10 parts of straw pulp fibers, 25 parts of bamboo pulp fibers, 15 parts of fiber cotton, and 10 parts of viscose fibers;

[0037] Step 2: Stir the mixed fiber material in step 1 with water at a stirring rate of 150r / min, and stir into a uniform slurry;

[0038] Step 3: Add auxiliary agents to the homogeneous slurry in step 2 and stir evenly for later use. The auxiliary agents include: 6 parts of whitening agent and 4 parts of preservative;

[0039] Step 4: making the metal wires for textile into linear, zigzag or net-like structures arranged at equal intervals and fixing the metal wire structure formed therearound. The diameter of the metal wires for textiles is 38um;

[0040] Step 5: soak the wire structure made in step 4 in polyvinyl alcohol or polyacrylamide or polyacrylic acid for 10 minutes;

[0041] Step 6: Apply the slurry treated in step 3...

Embodiment 2

[0044] Step 1: uniformly mixing the fibrous materials used for making paper, said fibrous materials comprising: 35 parts of wood pulp fibers, 8 parts of straw pulp fibers, 30 parts of bamboo pulp fibers, 5 parts of fiber cotton, and 11 parts of viscose fibers;

[0045] Step 2: Stir the mixed fiber material in step 1 with water at a stirring rate of 100r / min, and stir into a uniform slurry;

[0046] Step 3: Add auxiliary agents to the homogeneous slurry in step 2 and stir evenly for later use. The auxiliary agents include: 8 parts of whitening agent and 3 parts of preservative;

[0047] Step 4: Making the metal wires for textiles into linear, zigzag or mesh structures arranged at equal intervals and fixing the metal wire structure formed by them around, the diameter of the metal wires for textiles is less than 40um;

[0048] Step 5: soak the wire structure made in step 4 in polyvinyl alcohol or polyacrylamide or polyacrylic acid for 10 minutes;

[0049]Step 6: Apply the slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com