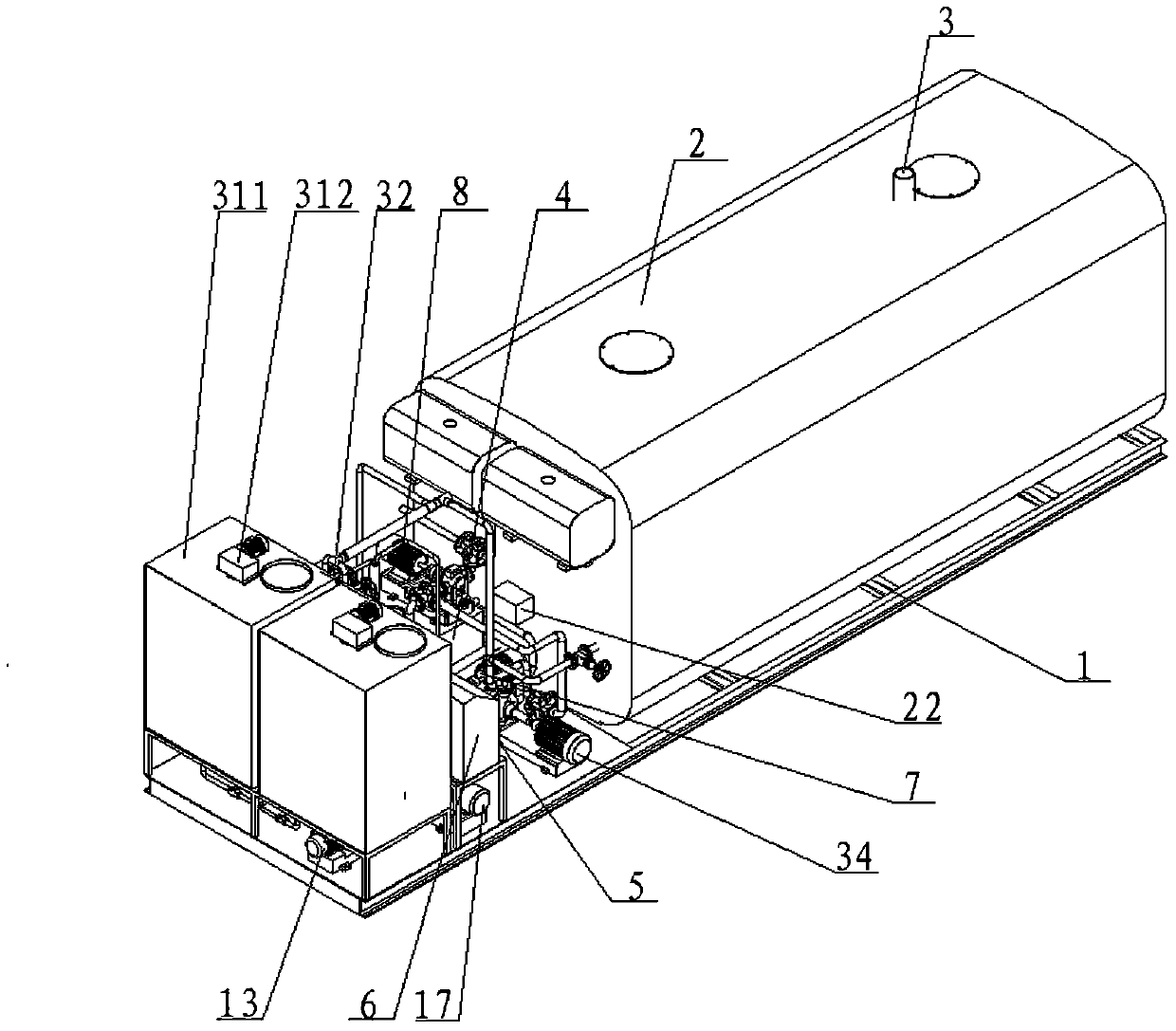

Integrated emulsified asphalt equipment

An emulsified asphalt, integrated technology, applied in the field of asphalt processing, can solve the problems of complex asphalt process, large volume, low utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

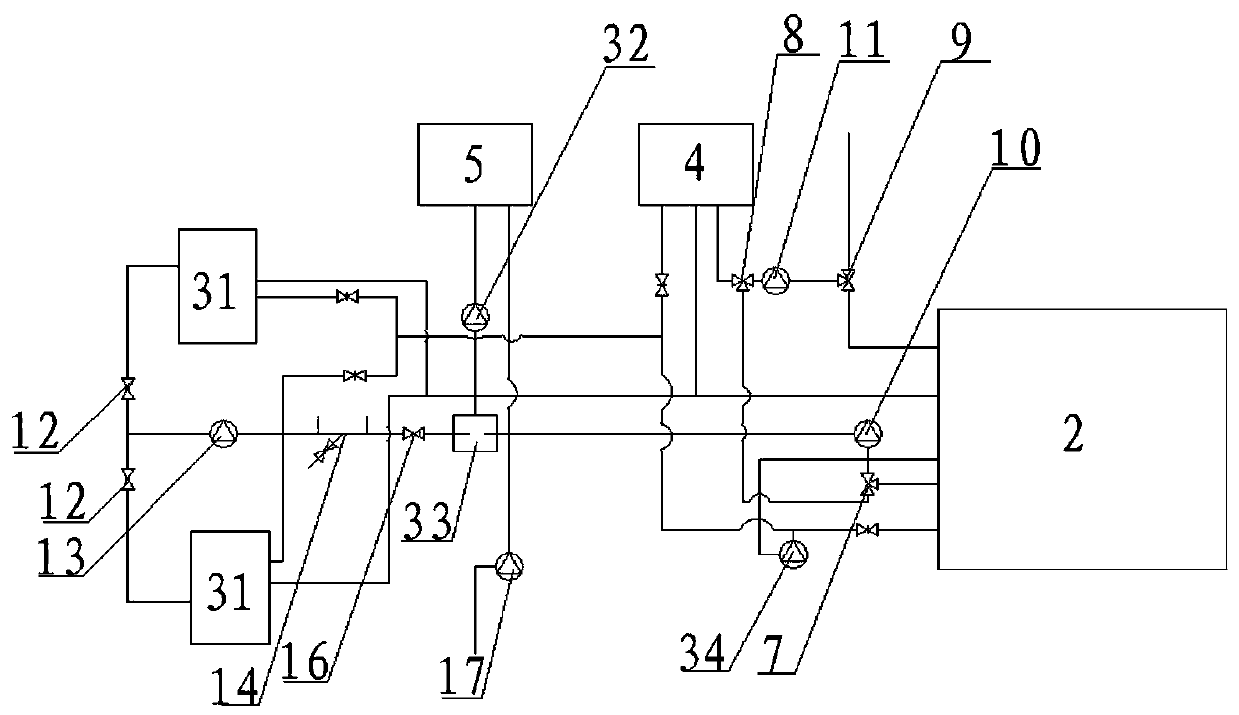

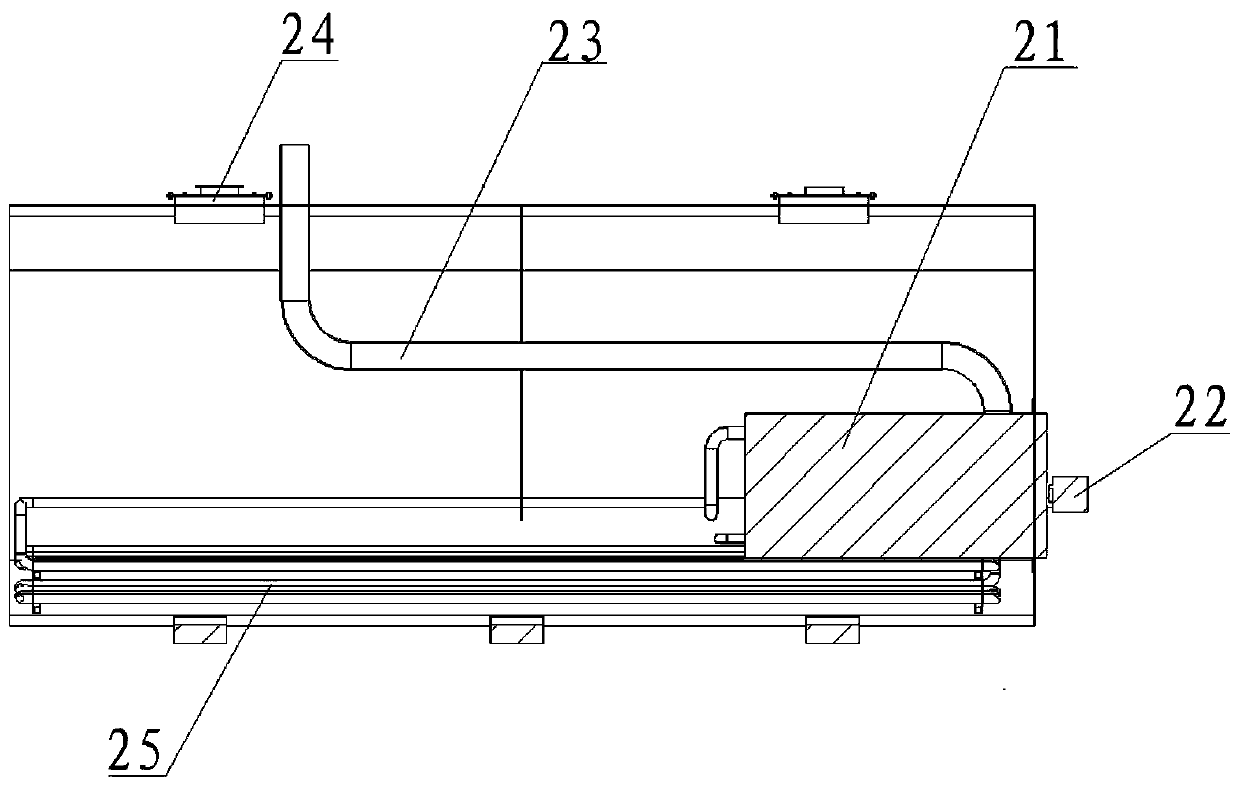

[0032] Set an asphalt insulation three-way valve 7 at the asphalt outlet of the asphalt tank, and the asphalt insulation three-way valve 7 is respectively connected to the insulation asphalt arc pump 10, the oil discharge tank insulation three-way valve 8 and the asphalt tank body 2;

[0033] The three-way heat preservation valve 8 of the drain tank is respectively connected to the drain tank 4, the three-way valve for asphalt heat preservation 7 and the outlet heat preservation asphalt arc pump 11, and the outlet of the heat preservation asphalt arc pump 11 is also provided with a circulation heat preservation three-way valve 9, respectively Lead to the asphalt tank body 2 and the outside world;

[0034] The base asphalt can pass through the asphalt insulation three-way valve 7 and the oil drainage tank insulation three-way valve 8 into the oil drainage tank 4, or it can pass through the outlet insulation asphalt arc pump 11 and then pass through the circulation insulation thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com