Mounting method for pure board structure assembled house

An installation method and house technology, applied in the direction of building structure, construction, etc., can solve the problems of poor integrity of assembled houses, achieve the effects of reducing worker strength and working environment, rapid assembly and disassembly, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as Figure 1 to Figure 14 Shown, the installation method of a kind of pure plate structure assembled house of the present invention, this method comprises the following steps:

[0042] 1) Foundation treatment; for multi-storey permanent houses, the foundation shall be excavated, backfilled, and compacted first, or treated in the form of foundation piles, and then the overall structure of the ring steel beams shall be made; for simple temporary houses, I-beams shall be directly used Connected as geosphere steel beams.

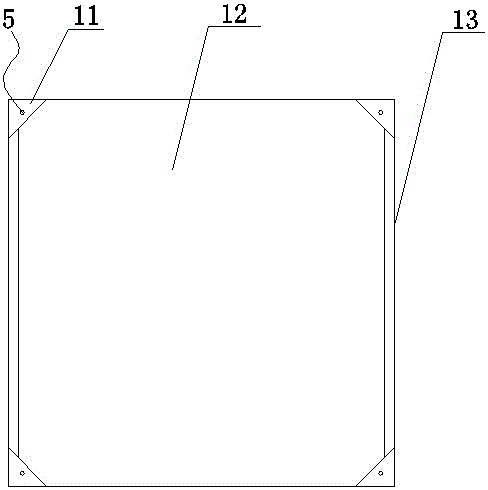

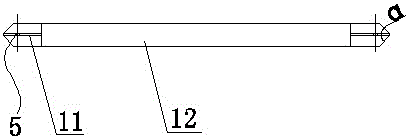

[0043] 2) Selection and processing of connecting components, composite wall panels and floor panels;

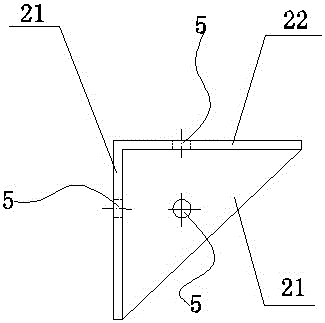

[0044] The connecting components include L-shaped split connector 2 for L-shaped butt walls, T-shaped split connectors 4 for T-shaped butt walls, and cross-type split connectors 6 for cross-shaped butt walls The L-shaped split connector 2 is composed of a floor connecting plate 22 and two wall connecting plates 21, the two wall connecting plates 2...

Embodiment 2

[0071] Such as Figure 1 to Figure 12 and Figure 15 to Figure 16 Shown, the installation method of a kind of pure plate structure assembled house of the present invention, this method comprises the following steps:

[0072] 1) Foundation treatment; for multi-storey permanent houses, the foundation shall be excavated, backfilled, and compacted first, or treated in the form of foundation piles, and then the overall structure of the ring steel beams shall be made; for simple temporary houses, I-beams shall be directly used Connected as geosphere steel beams.

[0073] 2) Selection and processing of connecting components, composite wall panels and floor panels;

[0074] The connecting member includes an L-shaped split connector 2 for L-shaped butt joint walls; the L-shaped split connector 2 is composed of a floor connecting plate 22 and two wall connecting plates 21, and the two wall connecting plates 21 are L-shaped. arrange, and make the two wall connecting plates 21 vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com