A kind of anti-cavitation environment-friendly cylinder liner

A cylinder liner, environmentally friendly technology, applied in the direction of cylinders, cylinder heads, machines/engines, etc., can solve the problems affecting the service life of internal combustion engines, insufficient fuel combustion, abrasive wear, etc., to reduce vibration, fully burn, reduce The effect of abrasive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

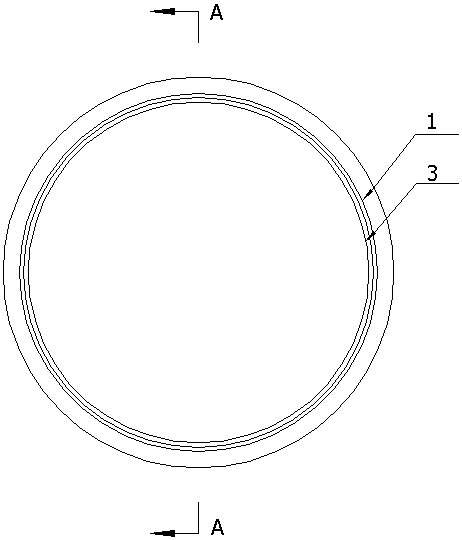

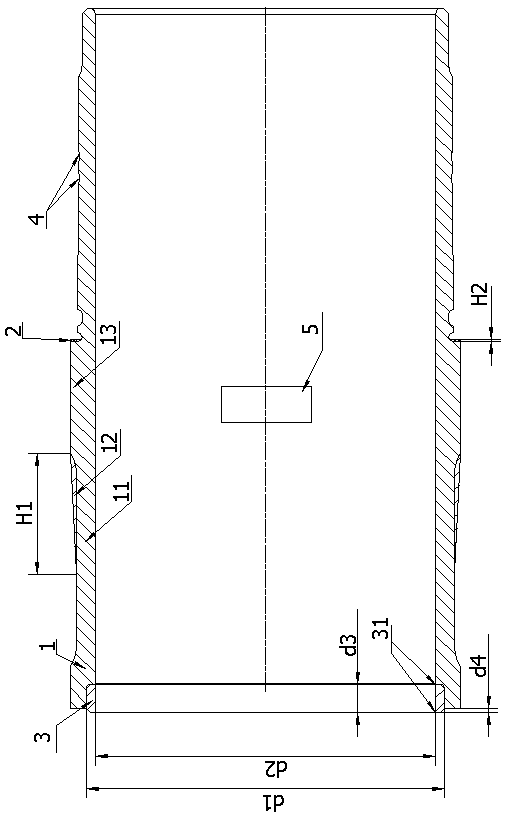

[0025] Such as figure 1 with figure 2 As shown, an environment-friendly anti-cavitation cylinder liner of the present invention includes a cylinder liner body 1, a waterway wall reinforcement structure is arranged on the waterway wall 11 of the cylinder liner body 1, and the waterway wall reinforcement structure includes a surrounding waterway wall 11 The reinforcement sleeve 12 arranged on the outer peripheral surface, the inner peripheral surface of the reinforcement sleeve 12 is fixedly connected with the wall surface of the waterway wall 11, the outer peripheral surface of the reinforcement sleeve 12 is set as a conical surface, and the conical surface faces the upper end of the cylinder liner body 1, the cone The wall connection between the surface and the water channel wall 11 has a smooth transition. The lower end surface of the supporting shoulder 13 of the cylinder liner body 1 is provided with a washer 2 , the washer 2 is a copper pad, and the washer 2 is sleeved o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com