Spring of double spiral structure

A double-helix structure and helical coil technology, applied in the direction of springs, springs/shock absorbers, coil springs, etc., can solve problems such as easy to be loosened, complex use of springs, lack of compression and rebound, etc., to achieve enhanced rigidity, The effect of simple structure and novel design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

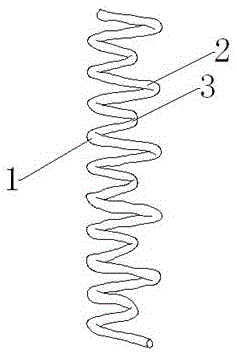

[0015] A double-helix structure spring, made of polyurethane material or spring steel, includes a spring body 1, the spring body 1 is composed of a number of continuous first helical coils 2 and second helical coils 3, and both ends of the spring body 1 are is the first helical turn 2.

[0016] The first helical coil 2 and the second helical coil 3 are distributed at intervals, and in a natural state, the distance between adjacent first helical coils 2 and second helical coils 3 is 0.5-2 cm.

[0017] The diameter of the first helical coil 2 is greater than the diameter of the second helical coil 3 , specifically, the diameter of the second helical coil 3 is 2 / 5˜2 / 3 of the diameter of the first helical coil 2 .

[0018] This kind of double-helix structure spring, in the presence of the second small-diameter helical coil, can effectively prevent the spring from being straightened when stretched and play a protective role; on the other hand, in the compressed state, the small dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com