Permanent magnetism positioning emergency plugging device based on pressure vessel fillet weld leakage

A pressure vessel and plugging device technology, applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve the problems of difficult to achieve emergency plugging of dangerous media, low plugging pressure, and long processing time. Achieve the effect of simple structure, high plugging pressure and fast installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

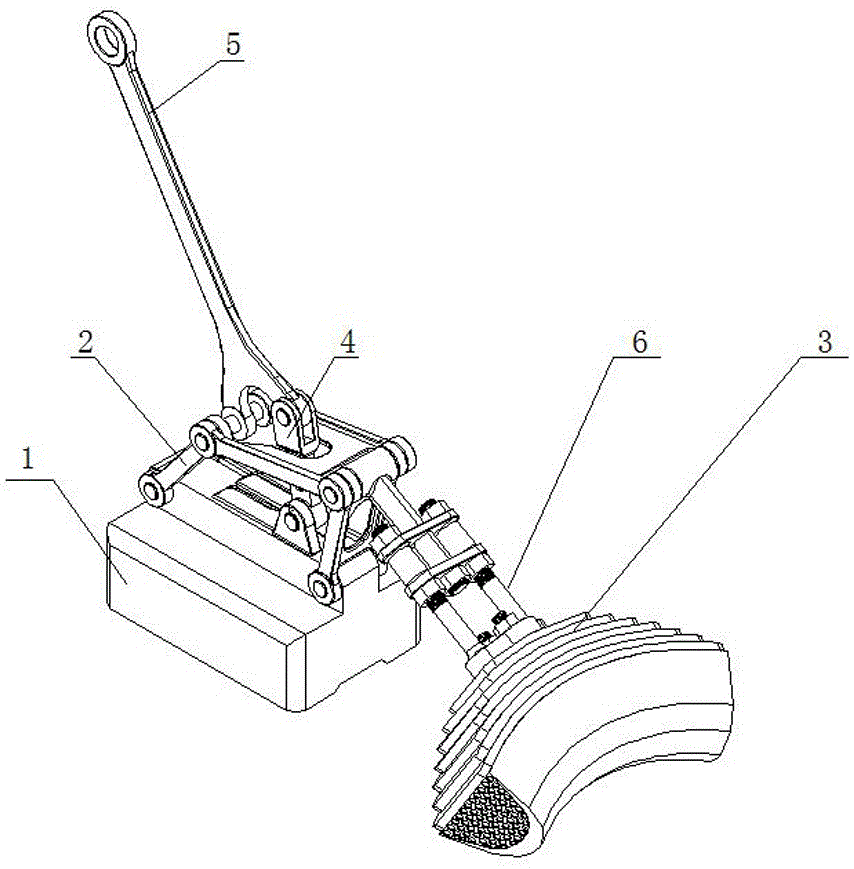

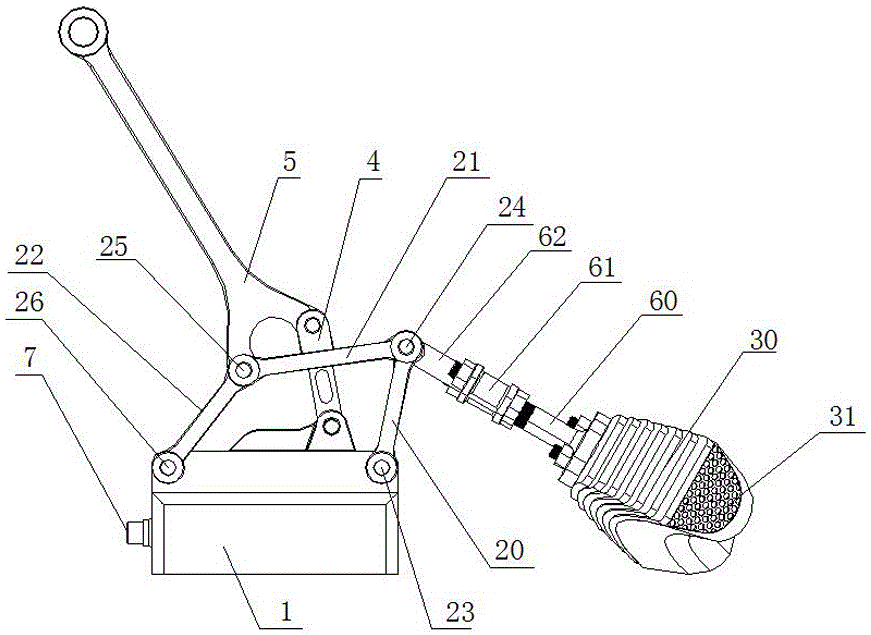

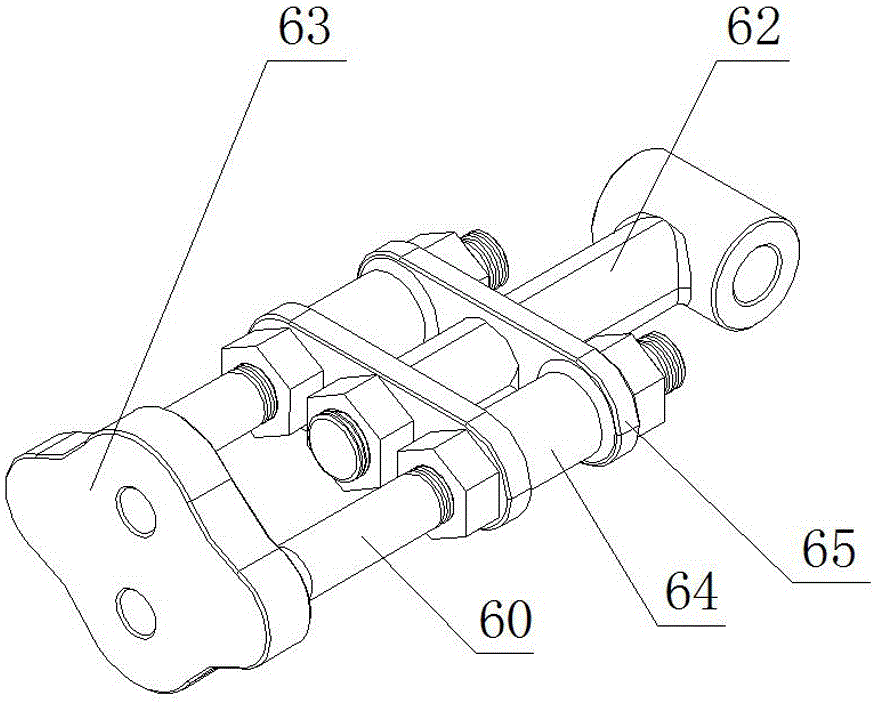

[0028] like Figure 1~Figure 6 As shown, the present invention is based on a permanent magnet positioning emergency plugging device based on pressure vessel fillet weld leakage, including a strong magnetic mechanism 1, a connecting rod mechanism 2 and a plugging assembly 3, and the connecting rod mechanism 2 is arranged in conjunction with the strong magnetic mechanism 1, the link mechanism 2 includes a front link 20, a middle link 21 and a rear link 22, and the front link 20, the middle link 21 and the rear link 22 are all sheet structures, and the One end of the front connecting rod 20 is hinged with the front end of the upper surface of the strong magnetic mechanism 1 through the first hinge 23, and the other end of the front connecting rod 20 is hinged with an end of the middle connecting rod 21 through the second hinge 24, and the middle connecting rod The other end of 21 and one end of rear connecting rod 22 are hinged by the third hinge 25, and the other end of describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com