Gel plugging material and preparation method thereof

A plugging material and gel technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as endangering construction safety and personnel life, affecting water injection development effect, poor construction effect, etc., to achieve plugging Strong adaptability, excellent plugging effect, and the effect of avoiding broken failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

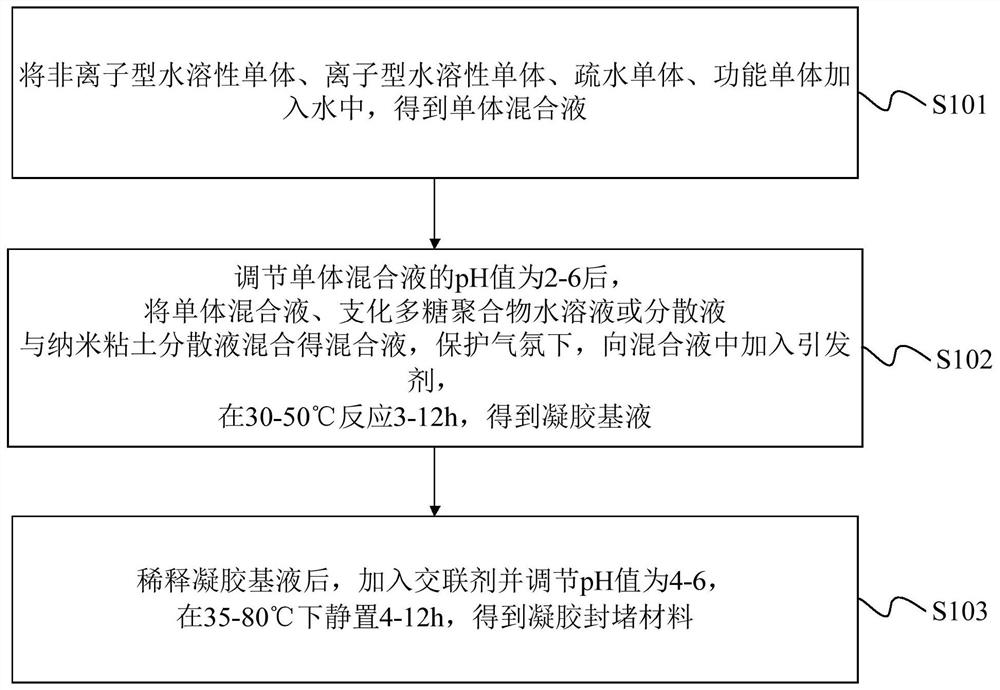

[0034] figure 1 Flowchart for the preparation method of gel sealing material of the present invention, such as figure 1 As shown, the preparation method of the gel seal material of the present invention includes the following steps:

[0035] S101: Non ion-type water-soluble monomer, ionic water-soluble monomer, hydrophobic monomer, function monomer, to obtain a monomer mixture;

[0036] Specifically, the nonionic water-soluble monomer is selected from one or more of acrylamide, N, N-dimethylacrylamide and methacrylamide. When a nonionic water soluble monomer is selected from one or more of the above substances, the present invention does not limit the ratio of each substance.

[0037] Ion-type water-soluble monomers include anionic water-soluble monomers and cationic water-soluble monomers, wherein the anionic water-soluble monomer is selected from the group consisting of acrylic acid, methacrylic acid and 2-acrylamide-2-methylpropulfonic acid. One or more of them;

[0038] Cat...

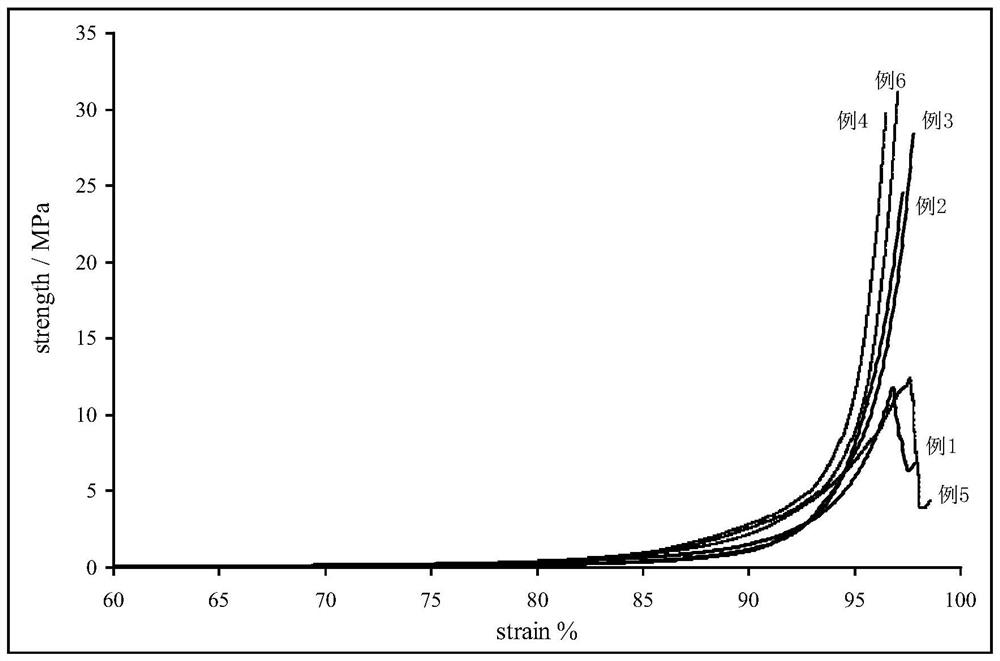

Embodiment 1

[0075] The preparation method of the gel sealing material of the present embodiment includes the following steps:

[0076] 1) Preparation of monomer mixed liquid

[0077] The nonionic water-soluble monomer, ion-type water-soluble monomer, hydrophobic monomer, functional monomer is added to water to obtain a monomer mixture;

[0078] Among them, the nonionic water soluble monomer is acrylamide;

[0079] Anionic water soluble monomer is acrylic acid;

[0080] Cationic water-soluble monomers are acryloyloxyethyltrimethyl ammonium chloride;

[0081] The hydrophobic monomer is hexholide;

[0082] Functional monomer is allyl amine;

[0083] Non ion-type water-soluble monomers, ionic water-soluble monomers, hydrophobic monomers of 30: 10: 0.2;

[0084] The molar ratio of the anionic water-soluble monomer and the cationic water soluble monomer is 1: 1;

[0085] The functional monomer is 5% of the total mass of the nonionic water soluble monomer, ionic water soluble monomer, and the total ...

Embodiment 2

[0098] The preparation method of the gel sealing material of the present embodiment is the same as step 1) in Embodiment 1, and step 3) is different, and step 3) specifically:

[0099] 3) Preparation of gel blockage materials

[0100] Select 7% of the gel base fluid in Example 1 was used as the preparation of gel blockage materials;

[0101]The crosslinking agent was added to a gel base solution to a mass fraction of 7%, and after stirring, the pH value was adjusted to 5, and the gel blockage material of the present embodiment was allowed to obtain a gel blockage material of the present embodiment.

[0102] Among them, the crosslinking agent is chromium sulfate, and the mass of the crosslinking agent is 0.14% of the mass of the gel base.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com