A kind of gel plugging material and preparation method thereof

A plugging material and gel technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as endangering construction safety and personnel life, affecting water injection development effect, poor construction effect, etc., to achieve plugging Strong adaptability, excellent blocking effect, and the effect of avoiding crushing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

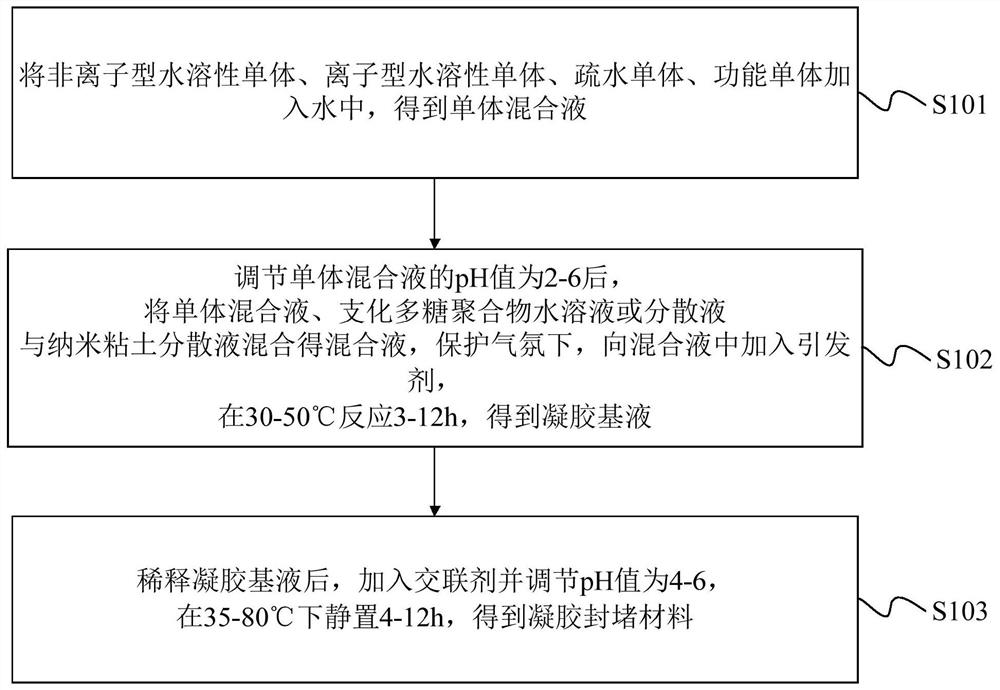

Method used

Image

Examples

preparation example Construction

[0040] The hydrophobic monomer is selected from one or more of hexenoic acid, undecenoic acid, and hexadecenoic acid. When the hydrophobic monomer is selected from the above

[0047] The above-mentioned nanoclay dispersion is a uniform and stable system that the nanoclay is added to water and stirred.

[0048] Specifically, the nanoclay is selected from one or more of bentonite, montmorillonite, diatomaceous earth and lithium magnesium silicate.

[0056] When the dilution of the gel base is completed, the cross-linking agent is added to the gel base and the acid is added under agitation

[0059] Further, the mass fraction of the monomer in the mixed solution is 5-50%.

[0063] Further, the mass fraction of nanoclay in the mixed solution is 0.5-15%.

[0064] That is, the mass fraction of the nanoclay in the mixed solution is 0.5-15%.

[0067] The present invention also provides a gel plugging material, obtained by any of the above-mentioned preparation methods.

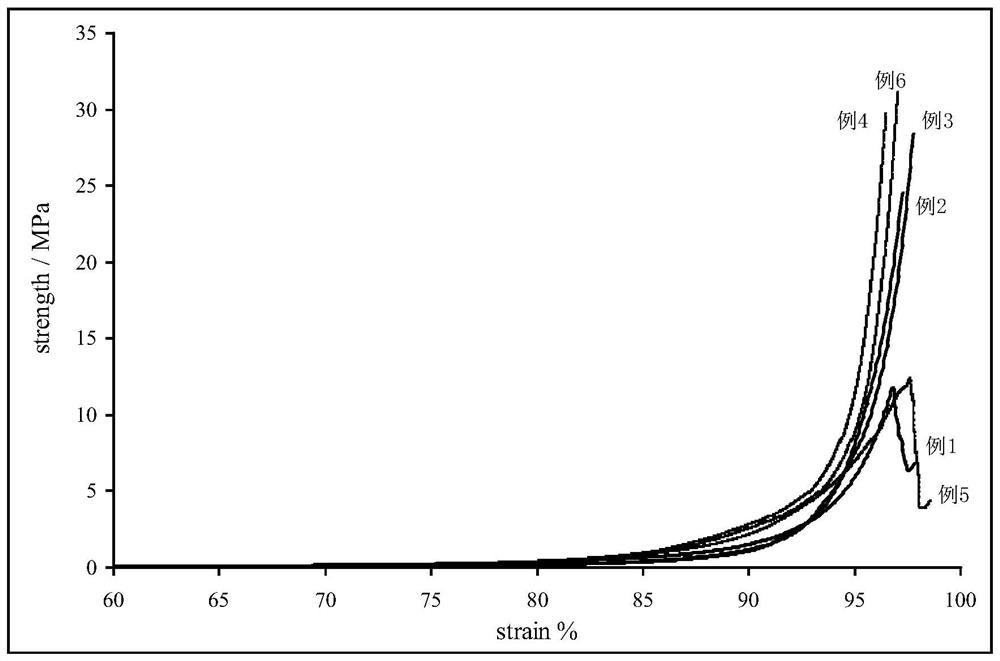

Embodiment 1

[0096] Wherein, the cross-linking agent is chromium sulfate, and the mass of the cross-linking agent is 0.1% of the mass of the 7% gel base liquid.

Embodiment 2

[0102] Wherein, the cross-linking agent is chromium sulfate, and the mass of the cross-linking agent is 0.14% of the mass of the 7% gel base liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com