Power module for equalizing currents of chips connected in parallel

A power module and chip technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as chip overcurrent burnout, power module reliability impact, serious heat generation, etc., so as to improve reliability and reduce the risk of burnout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

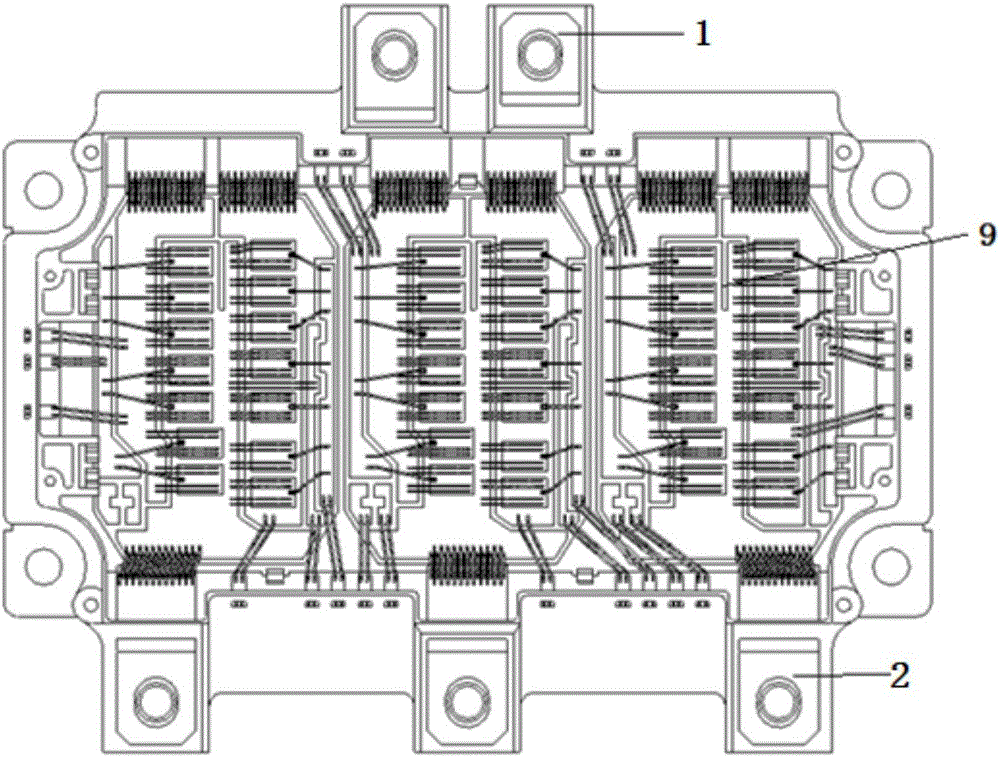

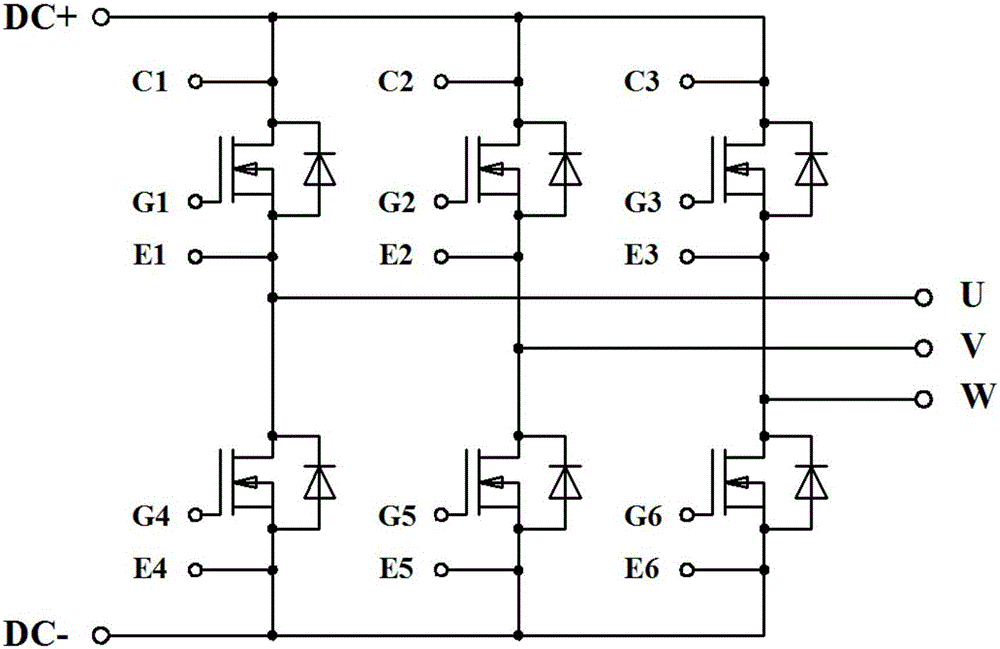

[0024] A power module with parallel chip current sharing, such as figure 1 As shown, it includes a DC input terminal 1, an output terminal 2, and three parallel half-bridge structures. The three half-bridge structures are arranged sequentially. Each half-bridge structure includes an insulating substrate and a chip assembly on the insulating substrate. In this embodiment, each A block insulating substrate is a half-bridge topology electrical structure, such as figure 2 As shown, each half-bridge structure is connected to an output terminal 2, all half-bridge structures are connected to two DC input terminals 1, and three half-bridge structures form a three-phase bridge electrical topology. Three insulating substrates, a chip assembly, a casing, and a bottom plate form a three-phase bridge power module.

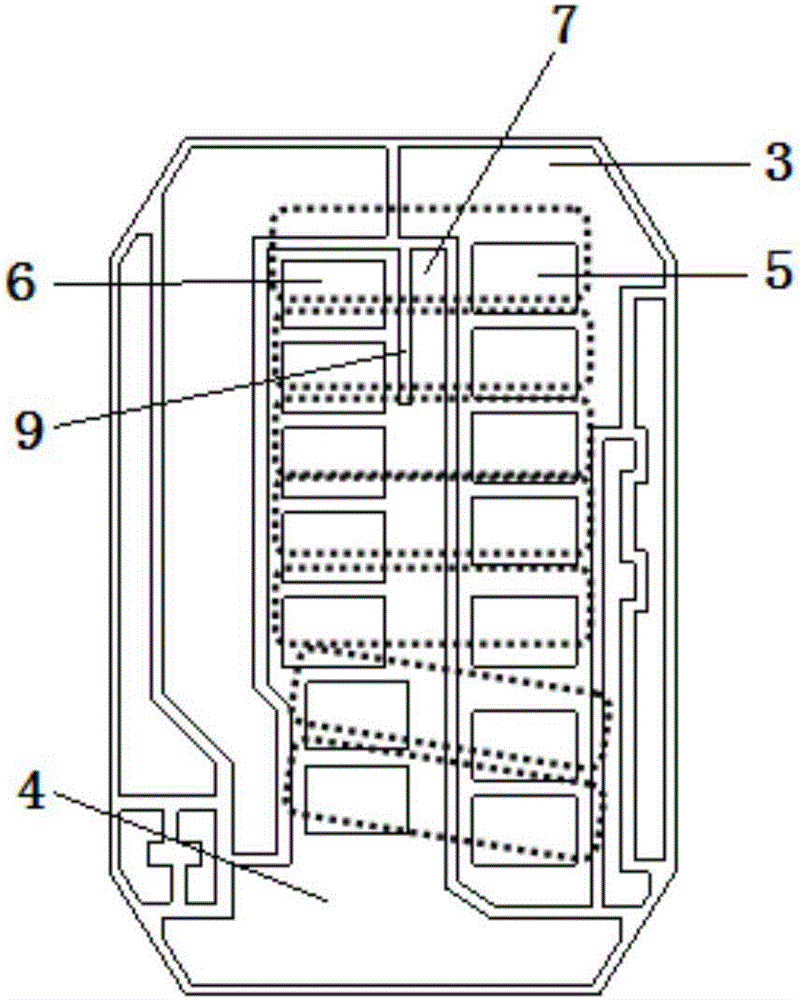

[0025] Insulating substrate structure such as image 3 As shown, it includes a ceramic insulating layer and a metal layer formed on the ceramic insulating layer. The materia...

Embodiment 2

[0036] This embodiment also provides a power module for parallel chip current sharing, its structure is roughly the same as that provided in Embodiment 1, the difference between the two is that the power module in this embodiment adopts the power module shown in Figure 4(c) The length balance groove 9 structure.

Embodiment 3

[0038] This embodiment also provides a power module for parallel chip current sharing, such as Figure 6 As shown, its structure is roughly the same as that provided in Embodiment 1. The difference between the two is that the chip types of the upper bridge arm chip unit 5 and the lower bridge arm chip unit 6 in this embodiment are IGBT and FRD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com