Vehicle-mounted-charger reverse connection prevention method

An on-board charger, anti-reverse connection technology, applied in the direction of collectors, electric vehicles, electrical components, etc., can solve the problems of the anti-reverse-connection circuit reducing the efficiency of the whole machine and the large conduction loss of the anti-reverse-connection circuit, so as to shorten the development time. cycle, reduce conduction loss, and improve the efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

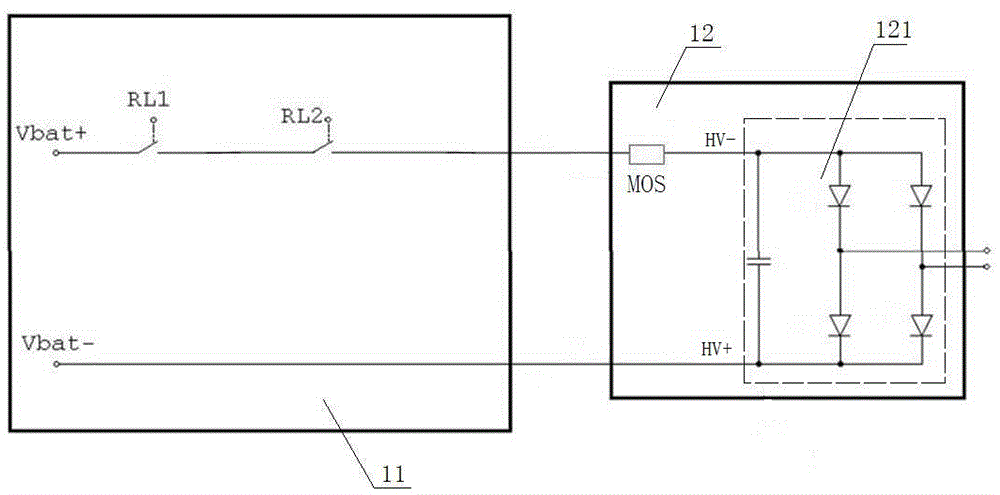

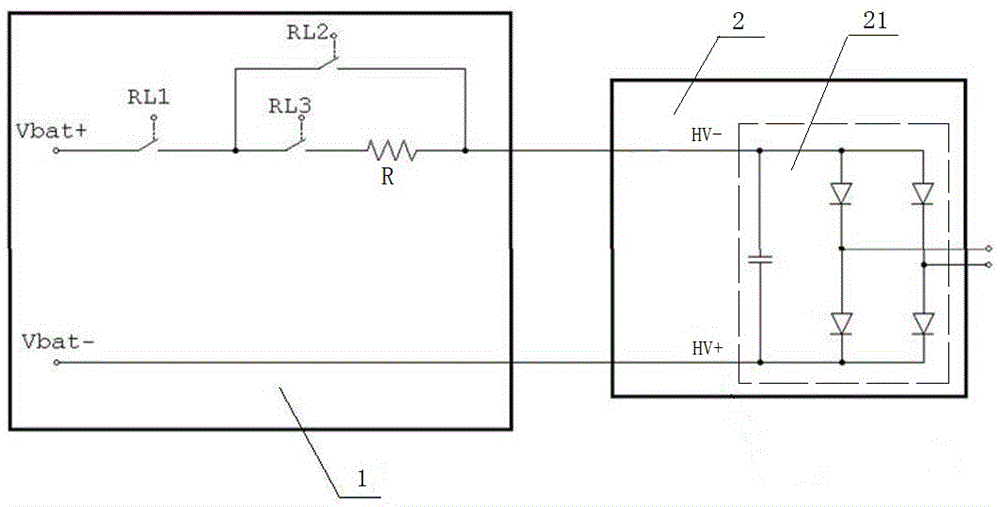

[0012] This on-board charger anti-reverse connection method adopts a figure 2 The anti-reverse connection circuit of the on-board charger shown, the anti-reverse connection circuit includes a branch formed by connecting the pre-charging resistor R and the pre-charging relay RL3 in series, and this branch is connected with the first battery management system 1 of the on-board charger. After the two relays RL2 are connected in parallel, one end thereof is connected in series with the first relay RL1 of the battery management system 1 and then connected to the battery voltage positive electrode Vbat+, and the other end thereof is connected to the negative end HV- of the high-voltage bus bar of the rectifying and filtering circuit 21 of the on-board charger 2; The positive terminal HV+ of the high-voltage bus of the filter circuit 21 is connected to the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com