Surface microphone calibration device

A technology for calibrating devices and microphones, applied in electrical components and other directions, can solve the problems of low calibration accuracy of surface microphones, lack of surface microphones, etc., and achieve the effects of convenient processing, avoiding internal cavity switching, and reducing calibration cycle and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

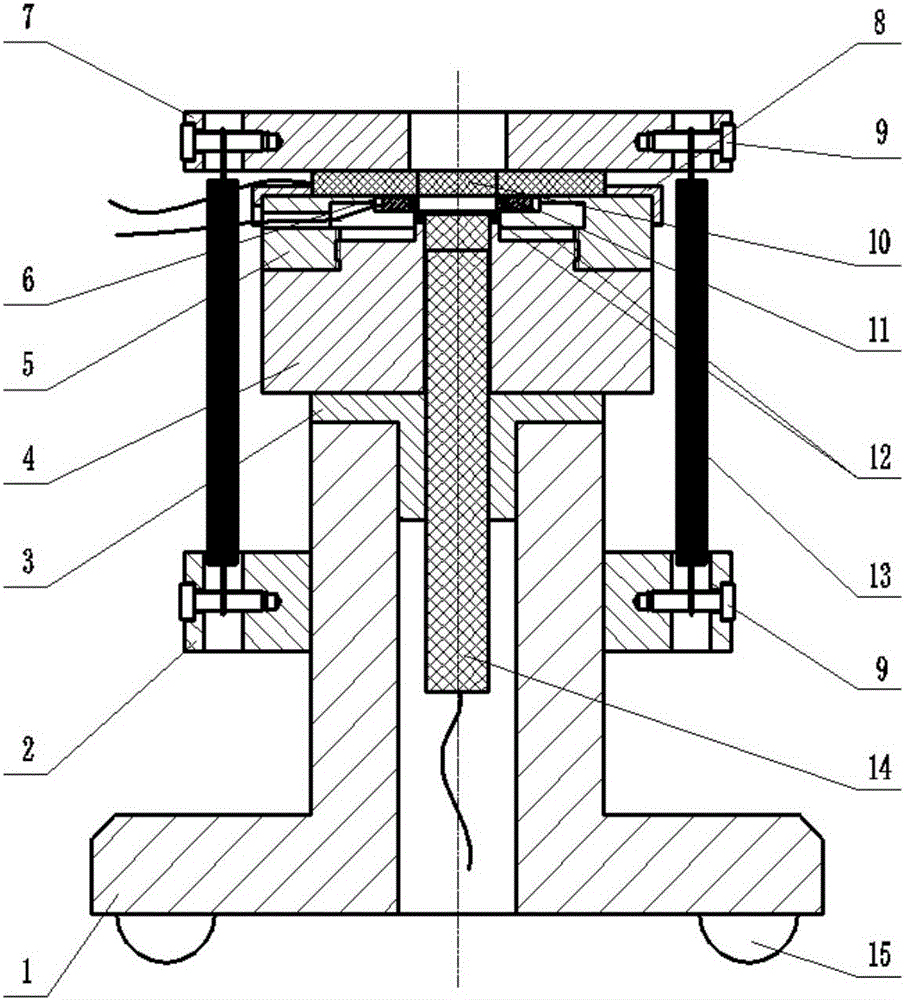

[0026] A surface microphone calibration device, the overall structure is as follows figure 1 As shown, the calibration object is a surface microphone 10 of any type, and the reference object is a 1 / 2-inch standard microphone 14 .

[0027] The device body consists of three parts:

[0028] 1. The base part, including: base 1, standard microphone cover 3, standard microphone 14, foot pad 15, which play the role of supporting device;

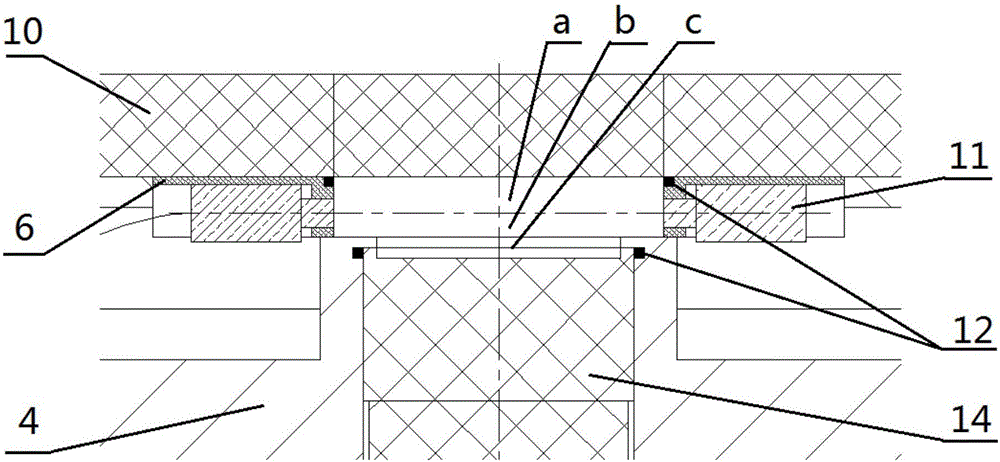

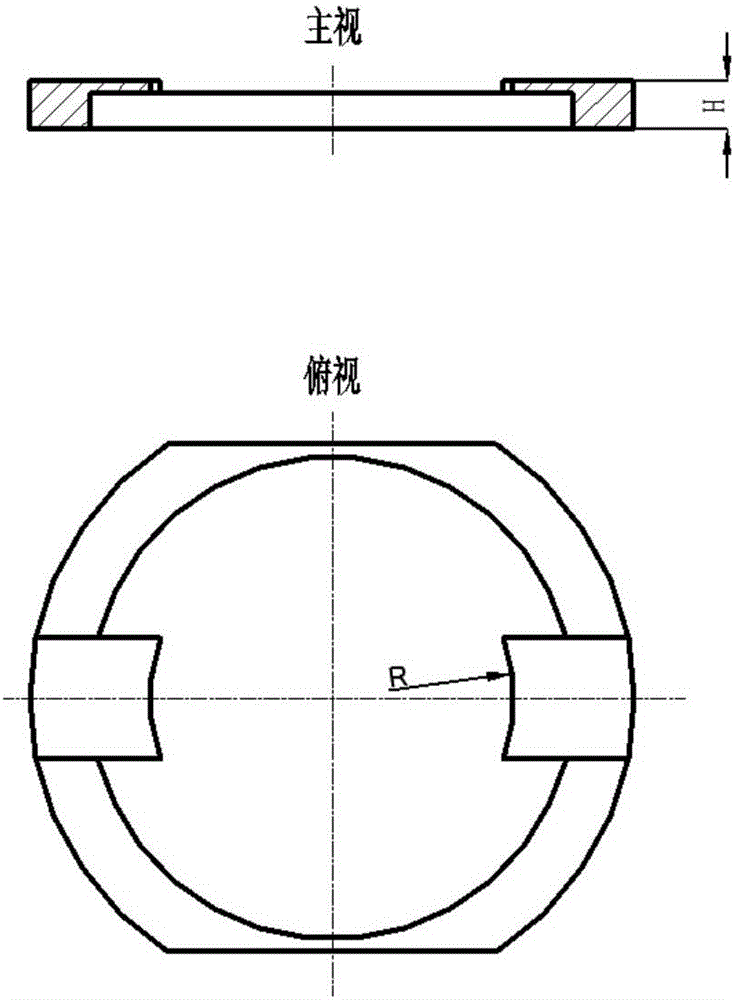

[0029] 2. The coupling cavity part, including the lower coupling cavity 4, the upper coupling cavity 5, the coupling cavity lining 6, the moving iron sound source 11, and the sealing O-ring 12, is the main body of the device, and its inner cavity is used for calibration;

[0030] 3. The clamping part, including the looper 2, the large-diameter gland 7, the surface microphone cover 8, the connecting bolt 9, and the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com