Spontaneous heating electric heat dissipating device for electronic device and optimization method therefor

A technology of electronic equipment and radiator, applied in the field of electronic equipment, can solve the problems of secondary waste, poor heat dissipation effect of heat dissipation device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

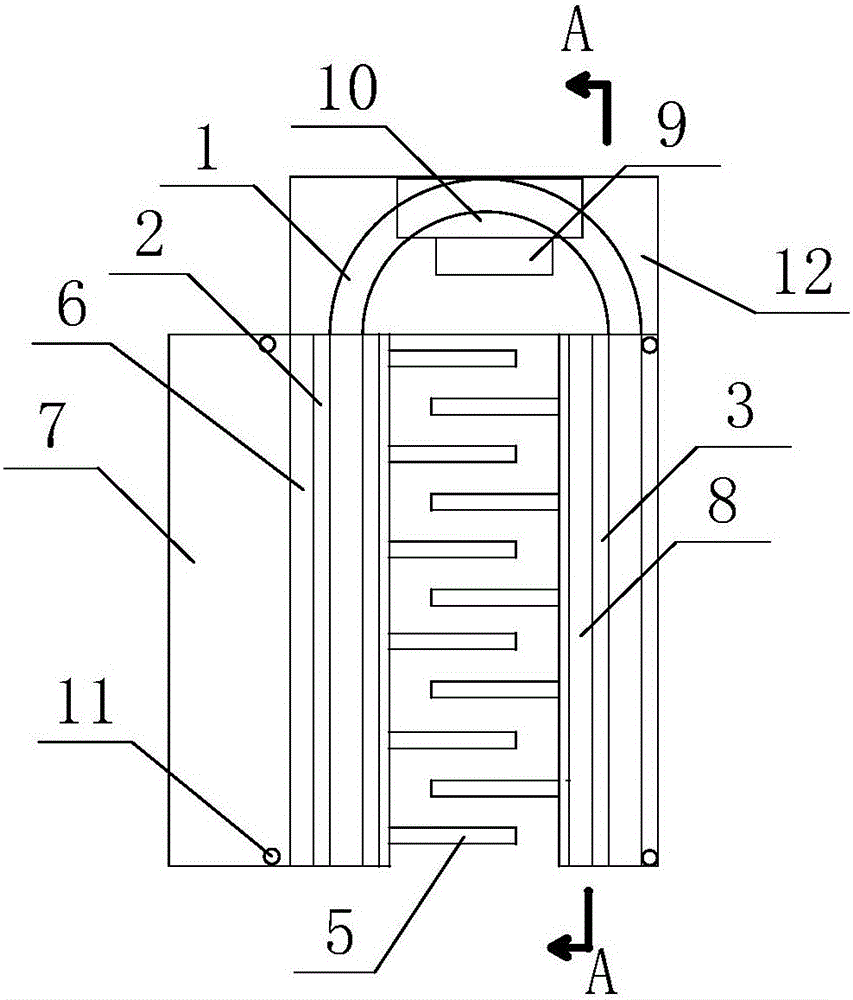

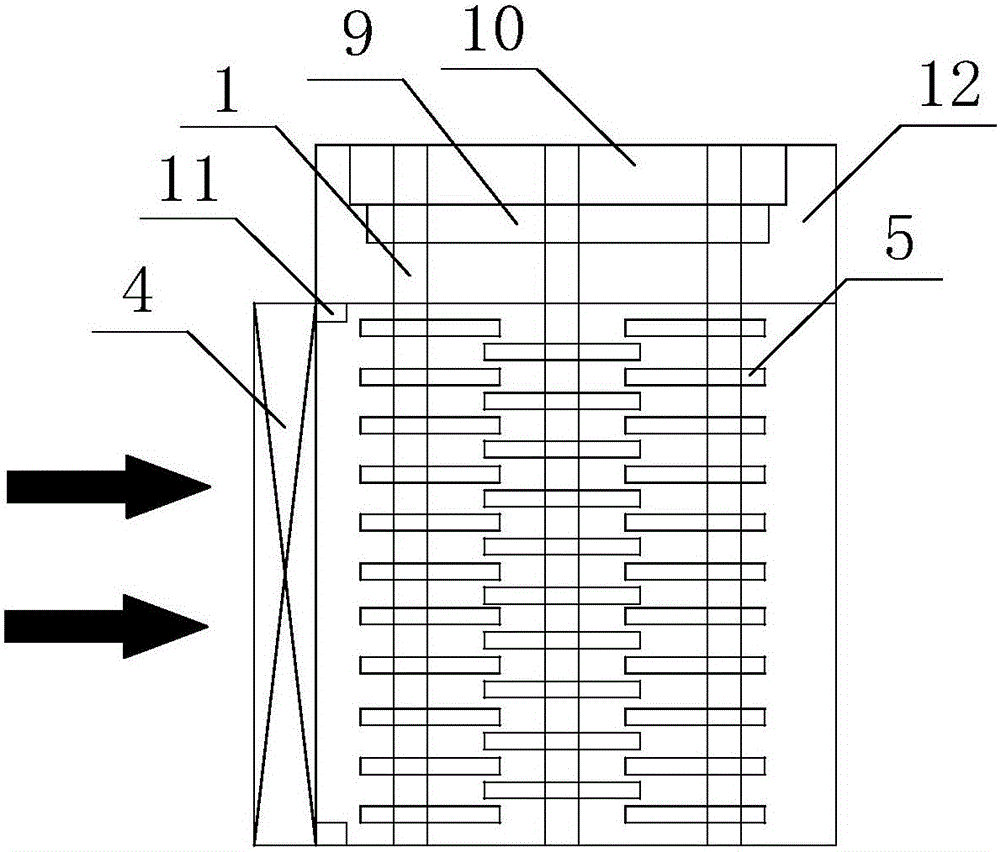

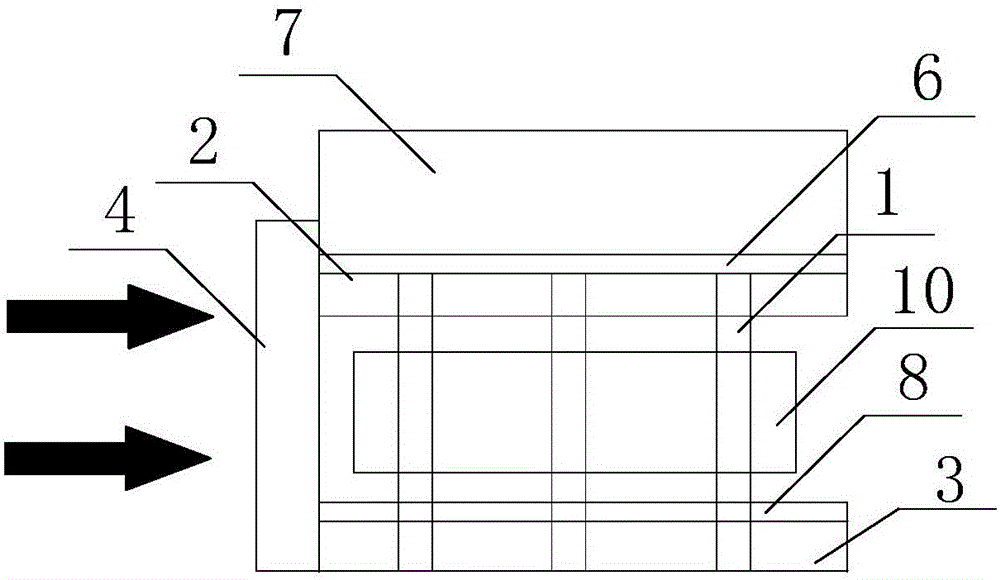

[0040] Embodiment one: see figure 1 , a self-heating electric radiator for electronic equipment, comprising a heat pipe 1, a heat pipe evaporating end substrate 2, a heat pipe condensing end substrate 3 and a fan 4, the heat pipe 1 is installed between the heat pipe evaporating end substrate 2 and the heat pipe condensing end substrate 3, Heat pipe evaporating end base plate 2 and heat pipe condensing end base plate 3 are both equipped with cooling fins 5, the cooling fins on heat pipe evaporating end base plate 2 and the cooling fins on heat pipe condensing end base plate 3 are in a staggered arrangement, heat pipe evaporating end base plate 2 is connected There is a thermoelectric power generation piece 6, and the thermoelectric power generation piece 6 is connected to the electronic equipment through the thermal extension block 7. A cooling piece 8 is inlaid on the heat pipe condensation end substrate 3, and the cooling piece 8 is electrically connected to a controller 9, an...

Embodiment 2

[0049] Embodiment 2: The difference from the specific embodiment 1 is that in the self-heating electric radiator for electronic equipment provided in this embodiment, see Figure 4 , the controller 9 is connected with thermocouple wires, and the thermocouple wires are installed between the thermal extension block and the electronic equipment. When the temperature of the electronic device is too high and exceeds the limit temperature, the thermocouple wire will transmit the temperature information to the controller, and the controller will start working according to the temperature information to perform temperature control.

[0050] Its working principle is the same as that of Embodiment 1, but in this embodiment, the controller can not only stabilize the electric energy generated by the thermoelectric power generation sheet to supply power to the cooling sheet and the fan respectively, so as to ensure the normal operation of the cooling sheet and the fan, but also the controll...

Embodiment 3

[0051] Embodiment 3: A method for optimizing a self-heating electric radiator for electronic equipment, the steps of which are: under the condition of a fixed temperature or a fixed heat dissipation on the surface of the electronic equipment, optimize the refrigeration sheet by optimizing formulas (1)-(8) The heat transfer performance parameter UA of the hot end, the area-thickness ratio f of the substrate at the condensing end of the heat pipe, and the flow rate V at the fan inlet, the area-thickness ratio f of the substrate at the condensing end of the heat pipe is defined as A e / L e , where A e Indicates the surface area of the substrate at the condensing end of the heat pipe, L e Indicates the thickness of the substrate at the condensing end of the heat pipe, and the expressions of the optimization formulas (1)-(8) are as follows:

[0052]

[0053] C O P = KϵQ C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com