Manufacturing method of single high-capacity lithium-ion battery and pole piece coating equipment

A lithium-ion battery and manufacturing method technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, and final product manufacturing, etc., can solve the problems of enlargement, the difficulty of flattening the diaphragm, the displacement of lithium and the like, and achieves a large single capacity and realizes the The effect of increasing the capacity of the single battery and ensuring the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

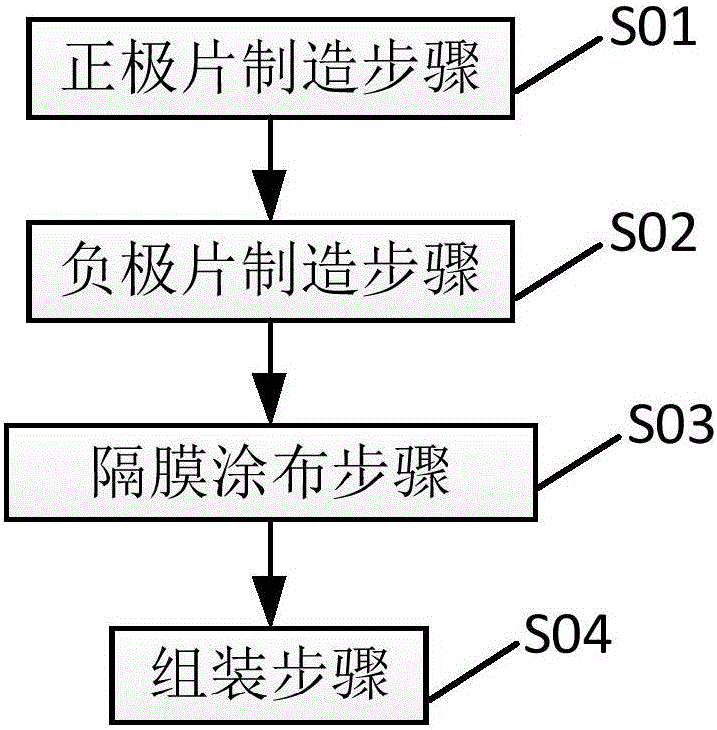

[0032] Please refer to figure 2 , the present embodiment provides a single high-capacity lithium-ion battery manufacturing method, comprising the following steps:

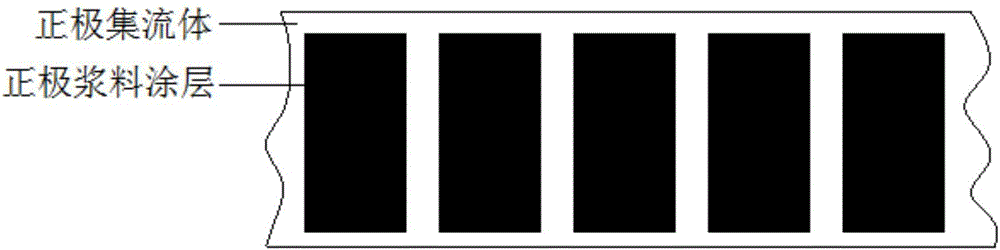

[0033] S01: a positive electrode sheet manufacturing step, for coating the prepared positive electrode slurry on the positive electrode current collector to obtain the positive electrode sheet.

[0034] S02: a negative electrode sheet manufacturing step, for coating the prepared negative electrode slurry on the negative electrode current collector to obtain the negative electrode sheet.

[0035] S03: Separator coating step. The separator coating step includes: preparing separator slurry; coating the separator slurry on one or both sides of the positive electrode sheet; and drying the positive electrode sheet coated with the separator slurry.

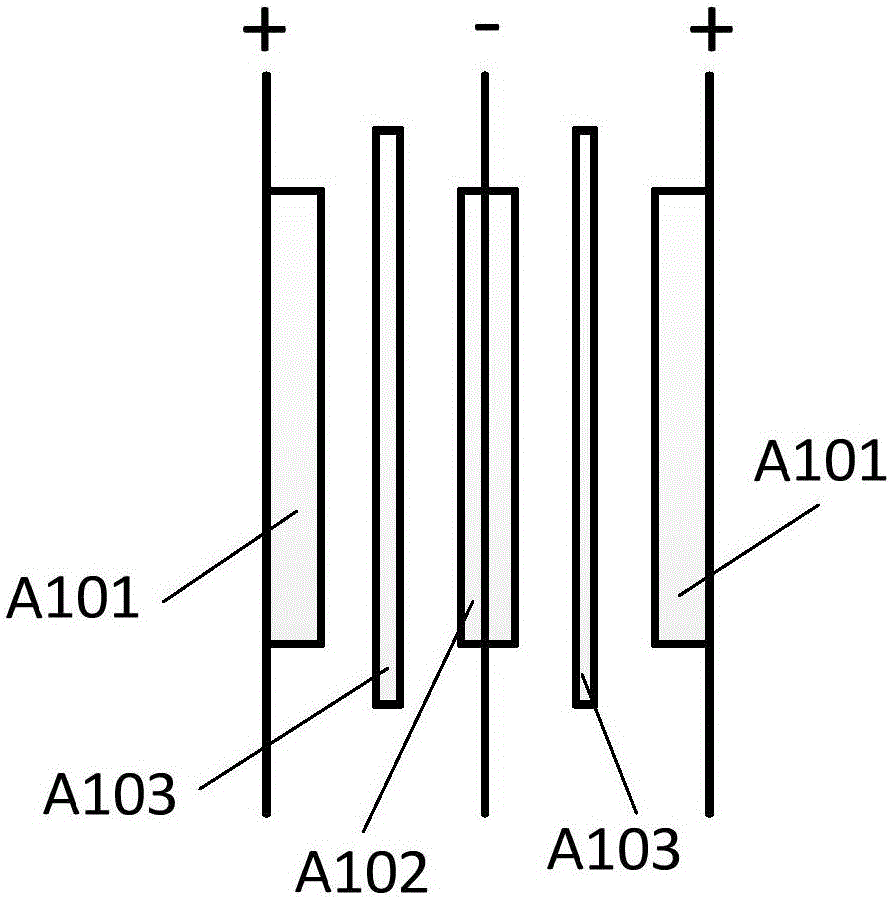

[0036] S04: The assembly step is used to sequentially stack the positive electrode sheet coated with the separator slurry and the negative electrode sheet according to the...

Embodiment 2

[0061] Please refer to Figure 7 , this embodiment provides a pole piece coating equipment used in the manufacturing method of a single large-capacity lithium-ion battery provided in the first embodiment above, including a first pole piece unwinding device 301, a separator slurry coating device 302, Drying device 303 and winding device 304.

[0062] The first pole piece unwinding device 301 is used for unwinding the whole roll of the first pole piece.

[0063] The diaphragm slurry coating device 302 is used for coating the prepared diaphragm slurry on one or both sides of the first pole piece. Preferably, the diaphragm slurry coating device 302 is used to apply the diaphragm slurry to one or both sides of the first pole piece by slit extrusion coating.

[0064] The drying device 303 is used for drying the first pole piece coated with the diaphragm slurry.

[0065] The winding device 304 is used for winding the first pole piece coated with separator slurry and dried.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com