Foetal membrane device of robot intelligent rolling and edge covering system

A robot intelligence, rolling hemming technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of lack of guidance and positioning function, cumbersome operation, long cycle, etc., to improve the quality of rolling operation and adsorption effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

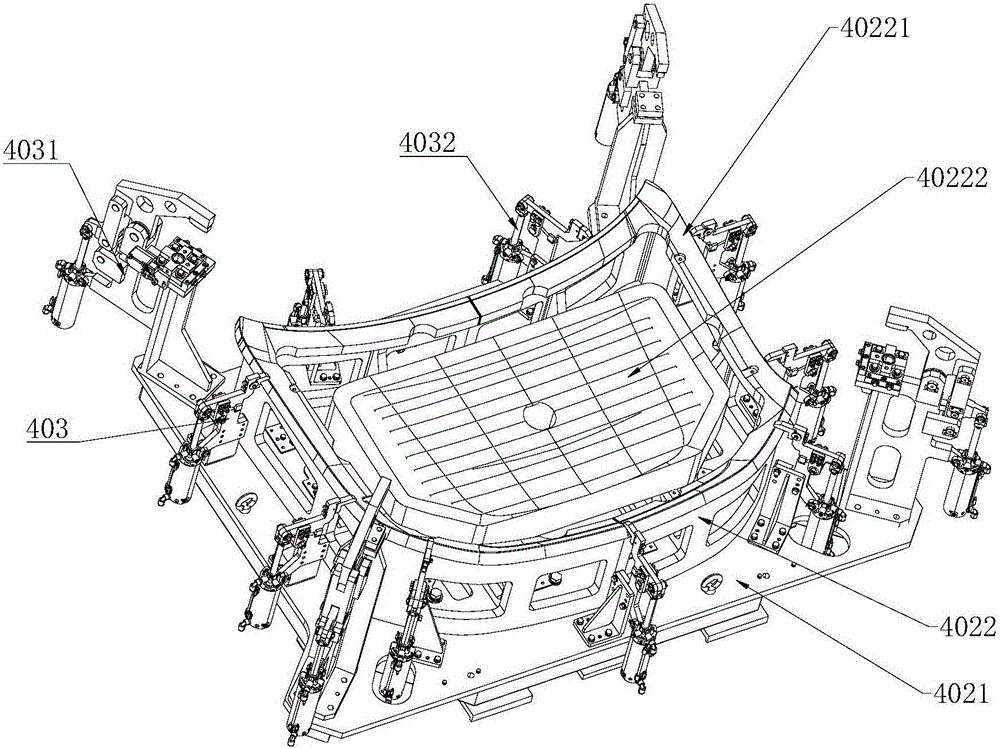

[0017] Such as figure 1 As shown, a membrane device of a robot intelligent rolling hemming system includes a membrane base 4021, the membrane base 4021 is a plate, and the membrane body 4022 is installed in the middle of the membrane base 4021; The mold 40221, the mold 40221 and the membrane body 4022 are integrally structured, the middle part of the membrane body 4022 is provided with a vacuum plate mounting block (not shown in the figure), and the vacuum plate 40222 is installed on the vacuum plate mounting block.

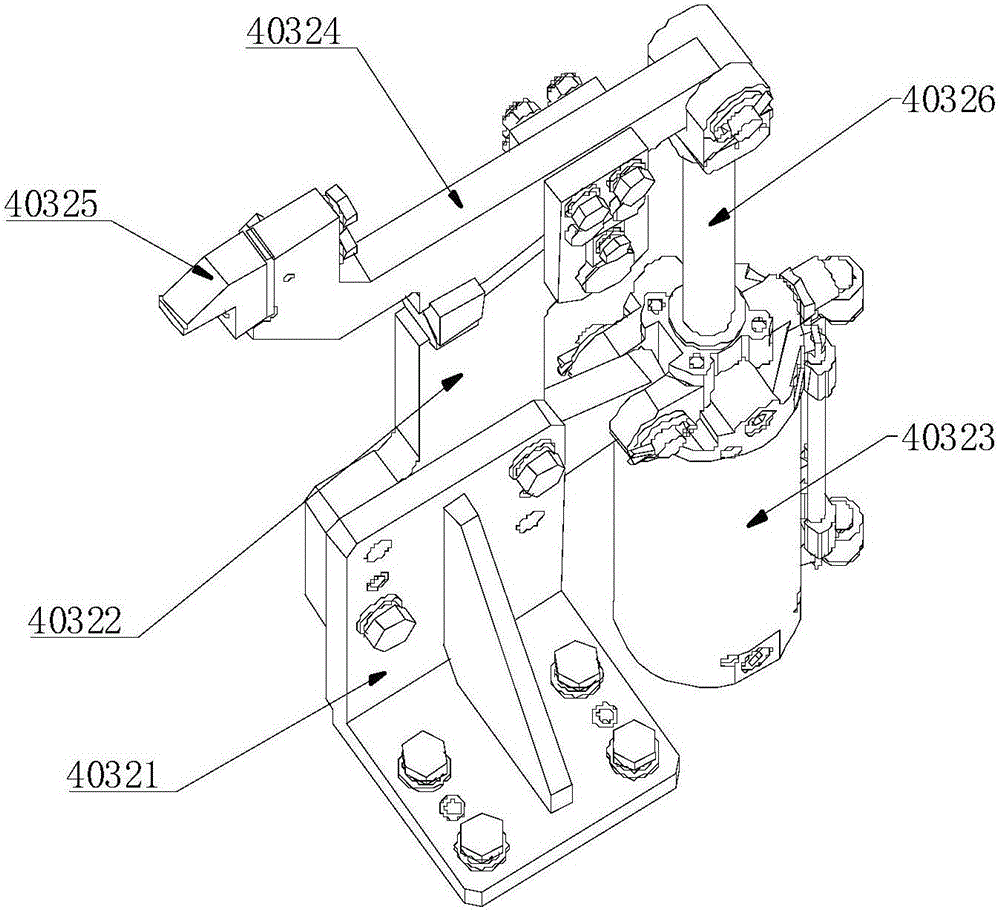

[0018] A rolling guiding and positioning system 403 is provided around the membrane body 4022, and the rolling guiding and positioning system 403 includes a handle locking mechanism 4031 and an outer plate guiding device 4032; the outer plate guiding device 4032 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com