Special lifting appliance for shield segment three-ring horizontal assembling

A shield segment and horizontal technology, which is applied in the field of special spreader for the three-ring horizontal assembly of the shield segment, can solve the problems of difficulty in ensuring the fine adjustment of the segment assembly position, damage to the edges and corners of the segment, and the existence of safety, so as to reduce the number of tubes The effect of eliminating chip breakage, improving construction efficiency, and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment:

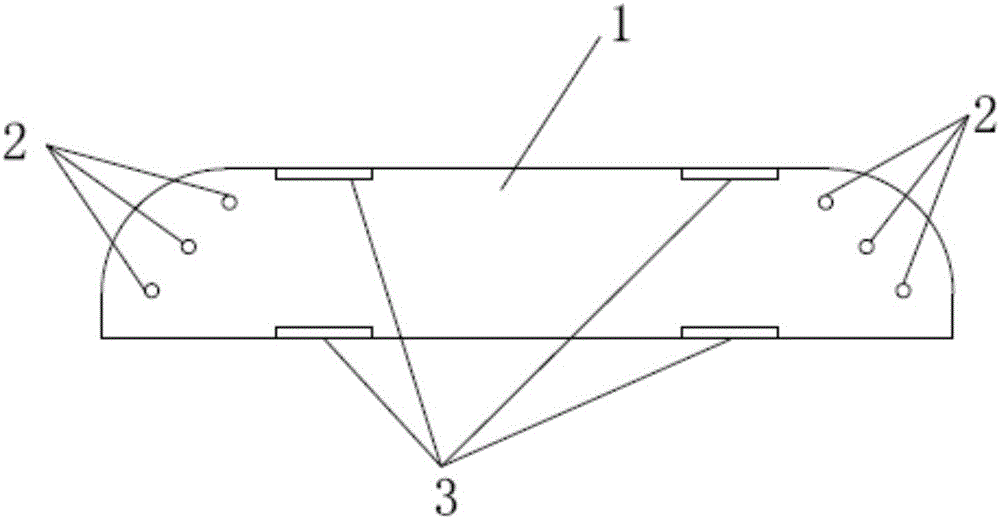

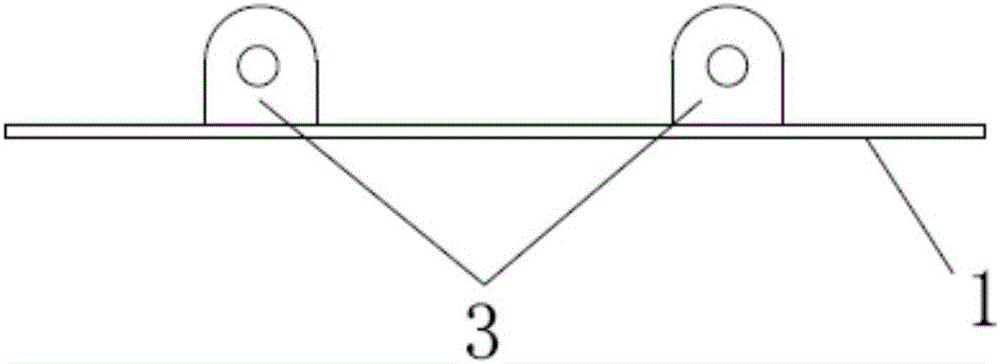

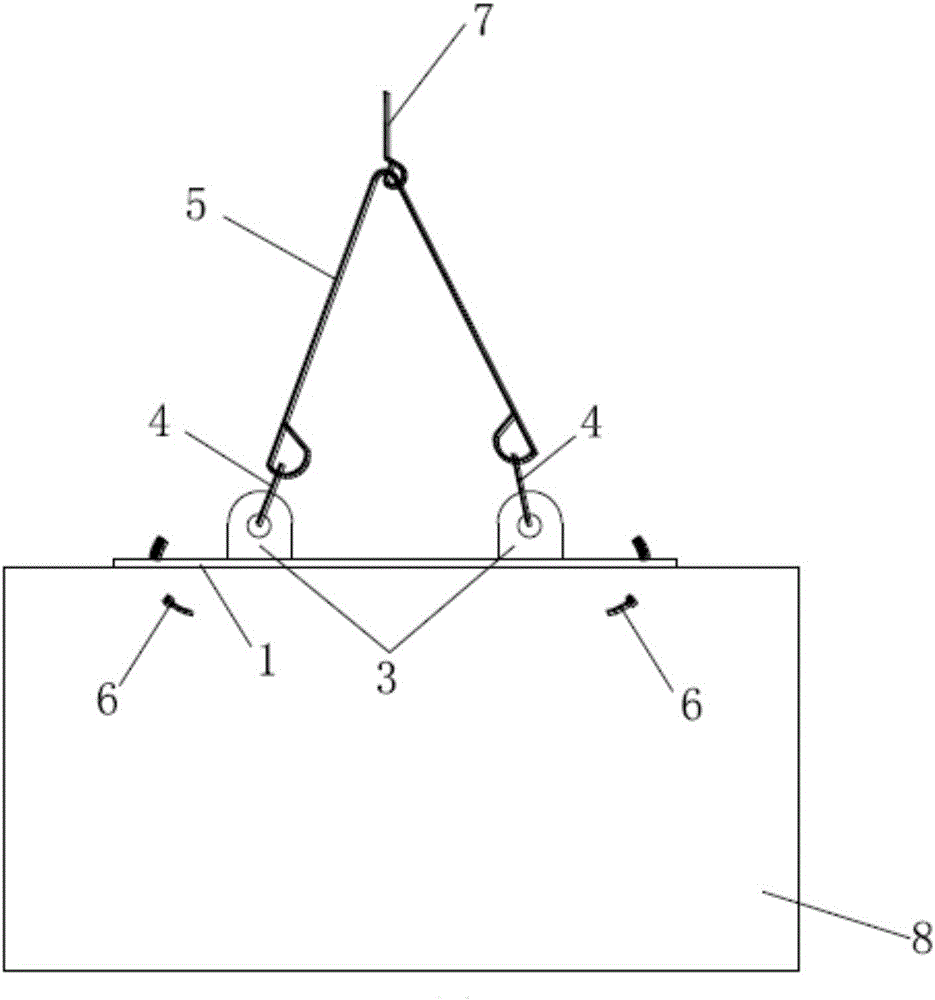

[0017] Such as figure 1 , figure 2 , image 3 As shown, a special spreader for the three-ring horizontal assembly of shield segments, including a hanging plate 1 with a length of 2000mm and a width of 200mm made of 20mm steel plate. The joints of the edges are designed with rounded corners. Two lifting lugs 3 are respectively welded on the two long sides of the hanging plate 1. The lifting lugs 3 are made of 20mm thick steel plates. There is a round hole with a diameter of 30mm inside the lifting lugs 3. There are three hanging holes 2 near the rounded corners at both ends of the short side of the plate 1. The diameter of the hanging holes 2 is 30mm, and the distance between the two hanging holes 2 at both ends is 1742.856mm (the horizontal projection distance of the upper hand holes of the segment 8).

[0018] The use of the special hoisting tool for the three-ring horizontal as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com