Novel tire sealing composite material containing 601 tackifying resin

A tackifying resin and new material technology, applied in the field of tires, can solve problems such as driving safety hazards, damage to the inner wall of the tire, and affecting the dynamic balance of the wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

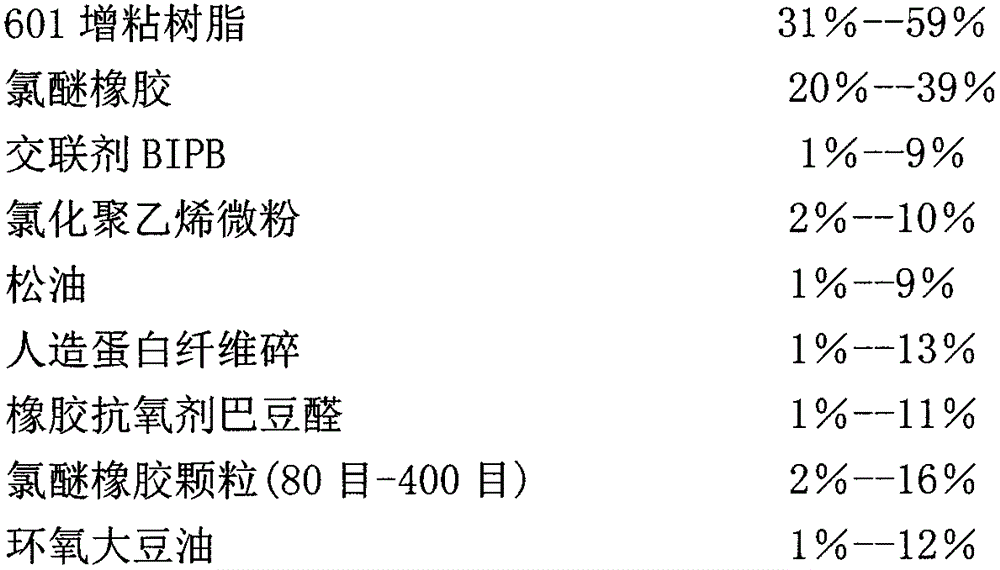

[0010] The composition and weight ratio of the new tire sealing composite material containing 601 tackifying resin are as follows:

[0011]

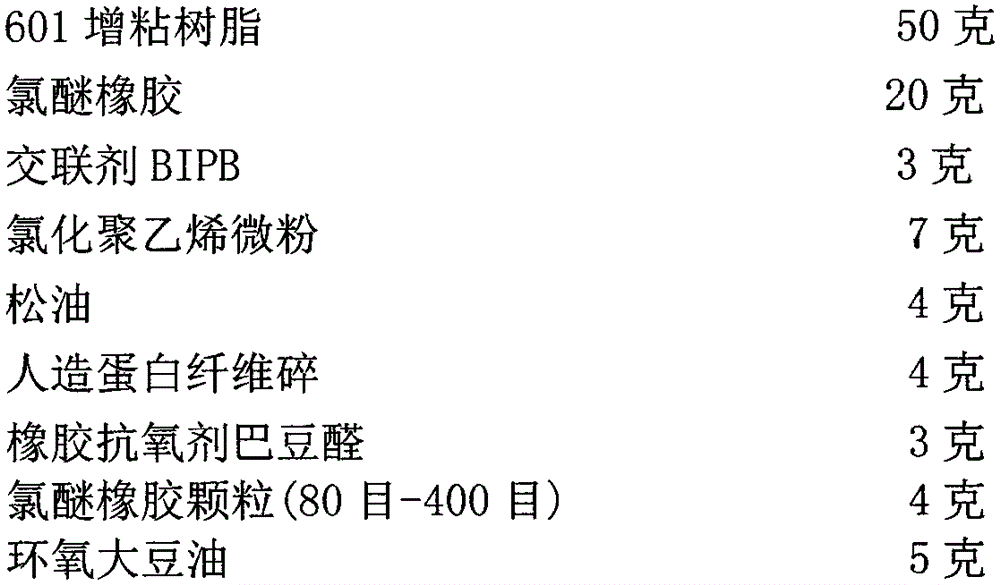

[0012] The present invention contains 601 tackifying resin tire sealing compound new material, and its preparation method is: put 50 grams of 601 tackifying resin, 20 grams of epichlorohydrin rubber, 3 grams of crosslinking agent BIPB, 4 grams of pine oil into a battery In the heated stirring tank, heat to 158°C and stir for 14 minutes after melting, then add 5 grams of epoxy soybean oil, 3 grams of rubber antioxidant crotonaldehyde and continue stirring for 11 minutes, then add 7 grams of chlorinated polyethylene micropowder, 4 gram artificial protein fiber fragments, 4 gram chloroether rubber particles (80 order-400 order) continue to stir for 13 minutes, finish after stirring evenly, obtain the yellowish-brown sticky thing with speckle to be the finished product of the present invention, it is removed from the stirred tank Pour out...

Embodiment 2

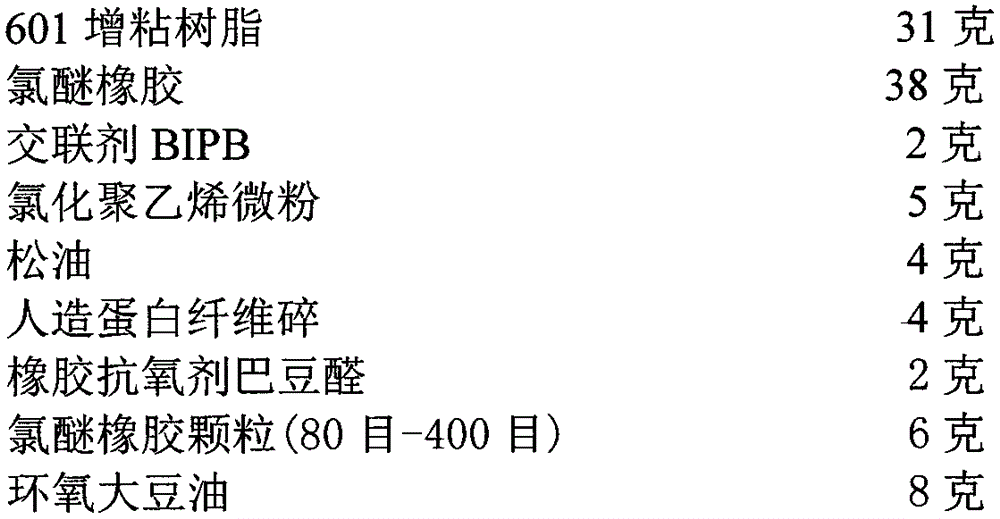

[0014] The composition and weight ratio of the new tire sealing composite material containing 601 tackifying resin are as follows:

[0015]

[0016] The tire sealing compound new material containing 601 tackifying resin, except that the weight ratio of its components is different, its preparation method is consistent with that described in Example 1.

Embodiment 3

[0018] The composition and weight ratio of the new tire sealing composite material containing 601 tackifying resin are as follows:

[0019]

[0020] The tire sealing compound new material containing 601 tackifying resin, except that the weight ratio of its components is different, its preparation method is consistent with that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com