An industrialized pre-processing regenerative structural system and its construction method

A construction method and regenerative technology, applied in truss structures, infrastructure engineering, building components, etc., can solve the problems of occupying wall space, poor sound insulation effect, long construction time, etc., and achieve strong energy consumption and sound insulation effect Good, the effect of improving the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

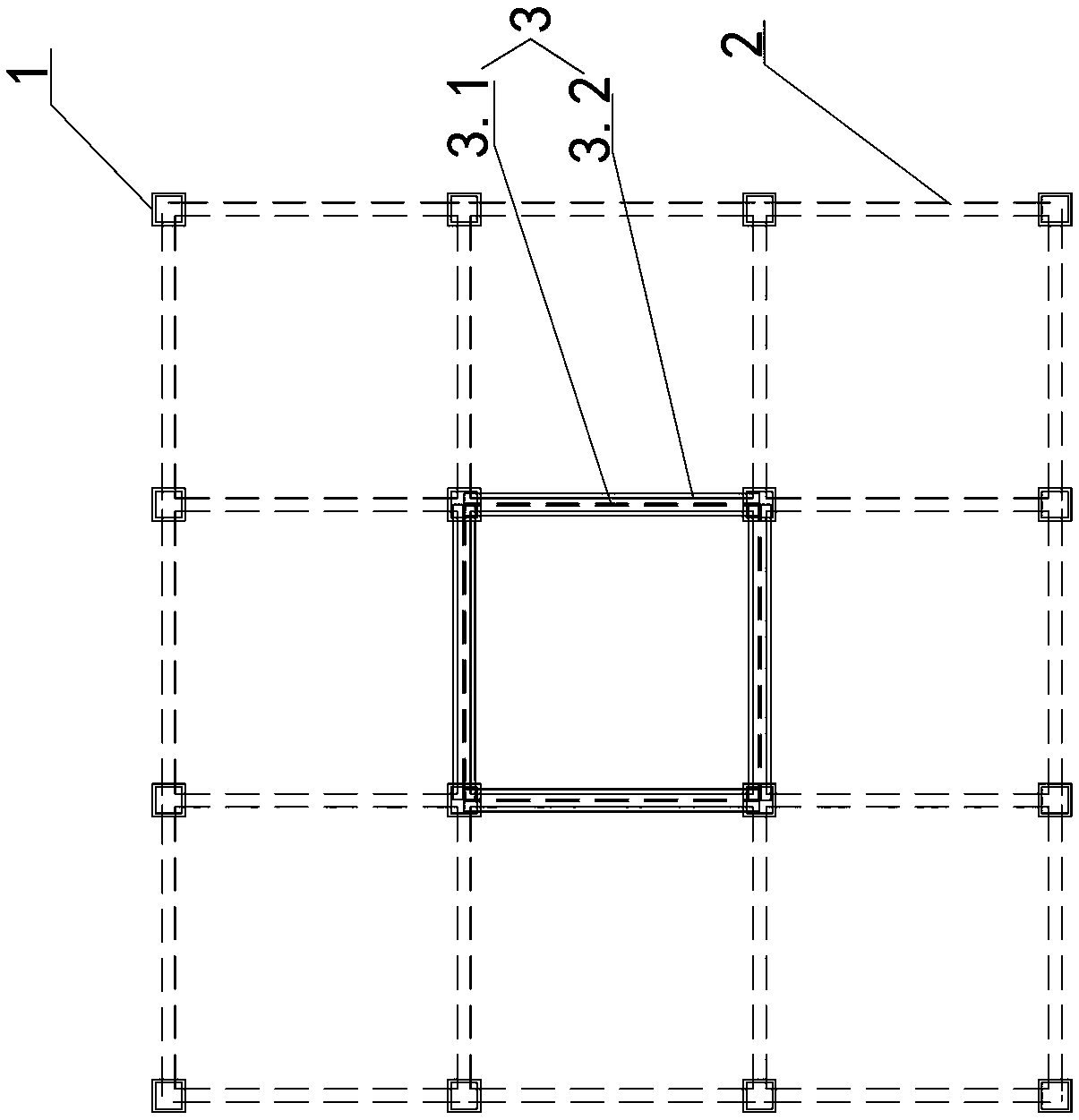

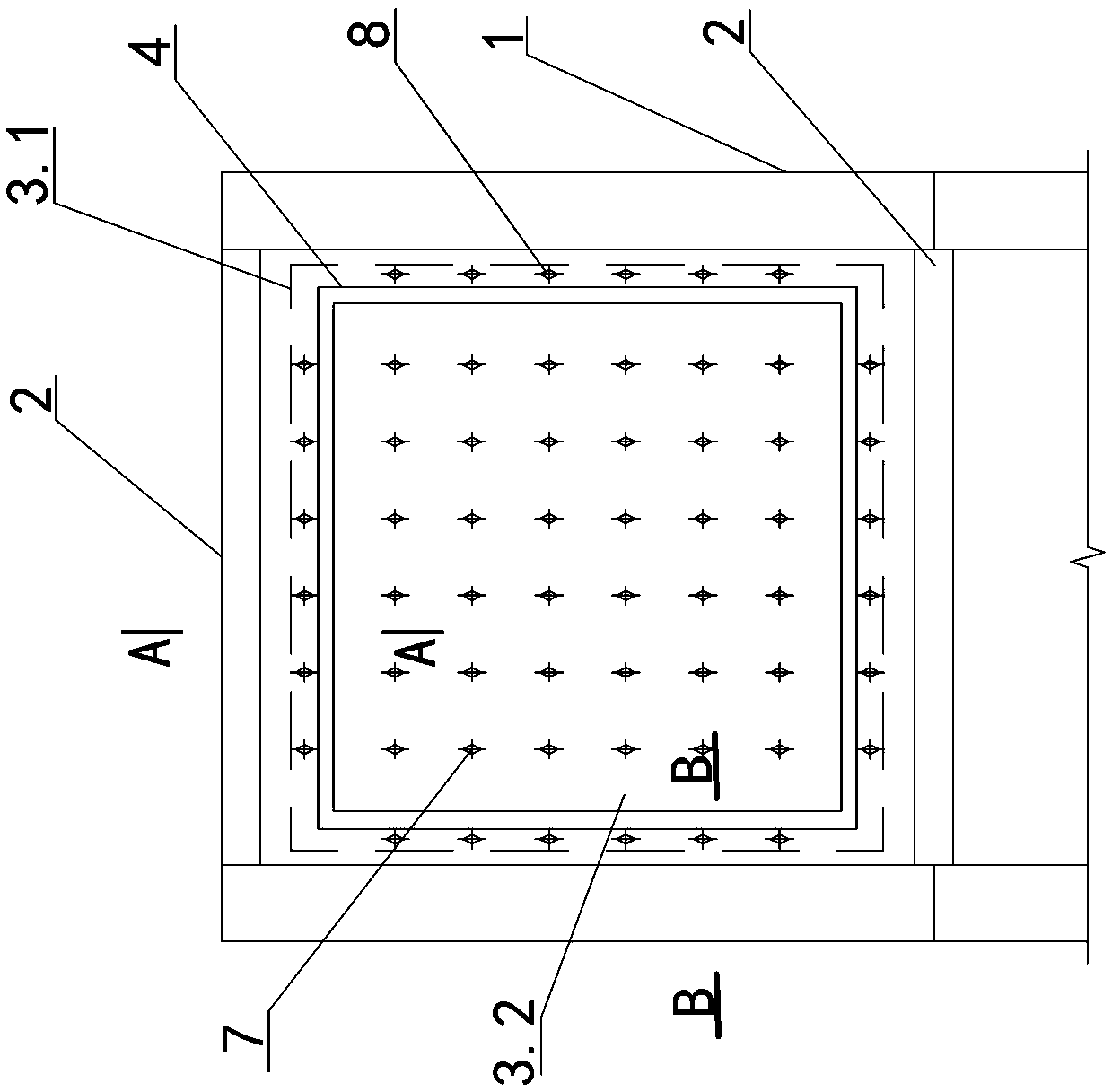

[0085] Embodiment one sees Figure 1-4 , 10-12, an industrialized pre-processing regenerative structural system, including a structural system composed of a foundation 11, a structural column 1, a structural beam 2, a shear wall 3 and floor connections.

[0086] The foundation is a reinforced concrete foundation, which may be an independent foundation, a raft foundation, a beam foundation, a box foundation, a pile foundation, a pile raft foundation or a pile box foundation.

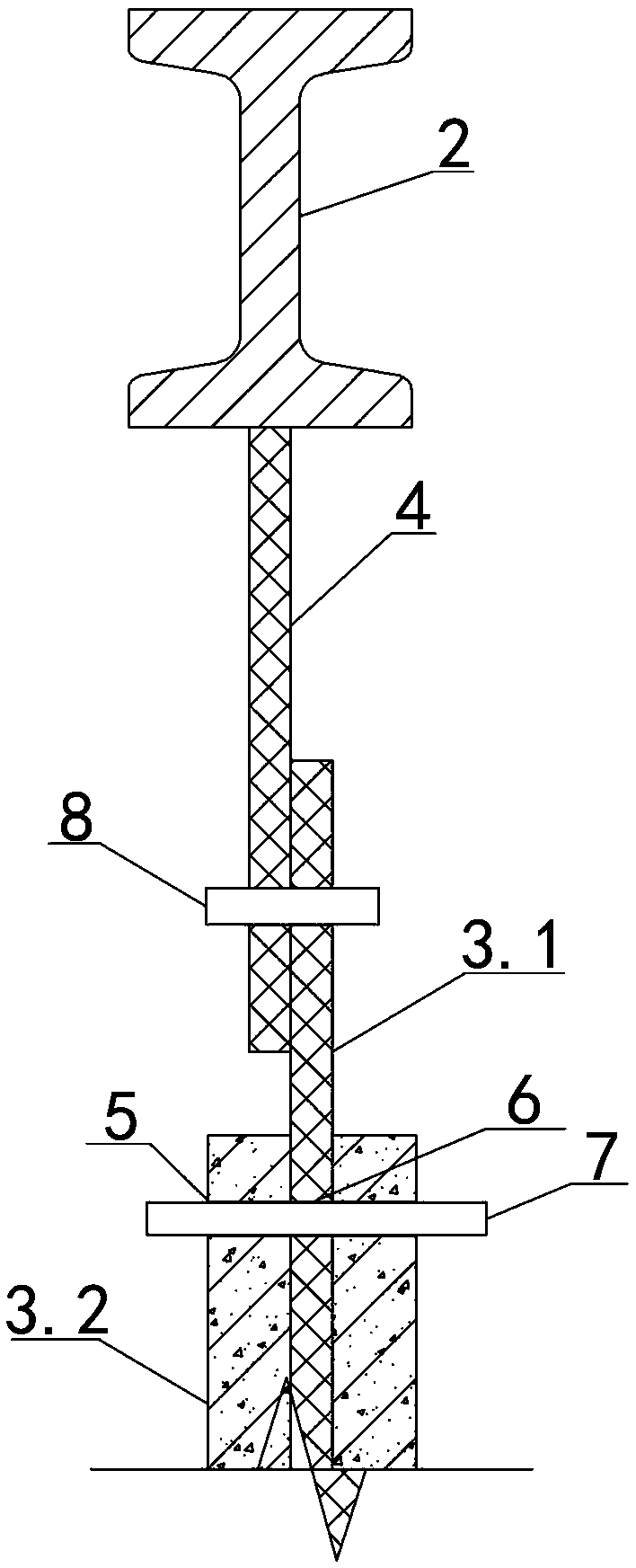

[0087] see Figure 4 As shown, the structural column is a steel tube concrete column, and the steel tube concrete column includes an outer steel cylinder 1.1 and a column concrete 1.3 filled with the outer steel cylinder. The column concrete is ordinary concrete, recycled concrete, high fly ash concrete or slag concrete.

[0088] The foundation and the structural column are fixedly connected by pre-embedded T-shaped anchors 13 .

[0089] The structural beam 2 is a steel beam, and the structural column ...

Embodiment 2

[0106] Embodiment two see Figure 1-11 As shown, the difference from Example 1 is that the structural column is a steel pipe reinforced concrete column, and the steel pipe reinforced concrete column includes an outsourcing steel cylinder 1.1, a core reinforcement cage 1.2 penetrating the column, and a column concrete filled with the outsourcing steel cylinder. 1.3. The core reinforcement cage 1.2 is composed of longitudinal bars 1.2a and stirrups 1.2b, and the longitudinal bars and stirrups are welded. In other embodiments there may be lap joints and mechanical connections.

[0107] The construction method of this industrial pre-processing regenerative structural system, the construction steps are as follows:

[0108] Step 1: Prefabricate the outer steel cylinder, core steel cage, connectors, steel plate shear wall core, out-of-plane restrained reinforced concrete prefabricated wall panels and steel beams in the factory, and the outer steel cylinder and core steel cage are p...

Embodiment 3

[0118] Embodiment three see Figure 6-11 As shown, an industrial prefabricated regenerative structural system, including a structural system composed of foundation 11, structural column 1, structural beam 2, buckling restraint support 9 and floor connections,

[0119] The foundation is a reinforced concrete foundation, which may be an independent foundation, a raft foundation, a beam foundation, a box foundation, a pile foundation, a pile raft foundation or a pile box foundation.

[0120] The structural column is a steel pipe reinforced concrete column, and the steel pipe reinforced concrete column includes an outer steel cylinder 1.1, a core reinforcement cage 1.2 penetrating the column body, and a column concrete 1.3 filled with the outer steel cylinder. The core reinforcement cage 1.2 is composed of longitudinal bars 1.2a and stirrups 1.2b, and the longitudinal bars and stirrups are welded. In other embodiments there may be lap joints and mechanical connections.

[0121] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com