Prefabricated reinforced concrete member and manufacturing method thereof

A reinforced concrete and manufacturing method technology, applied in the direction of manufacturing tools, truss structures, building materials, etc., can solve problems such as insufficient connection performance, achieve the effects of delaying the final setting time, improving performance, and facilitating the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The prefabricated reinforced concrete member and its manufacturing method of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

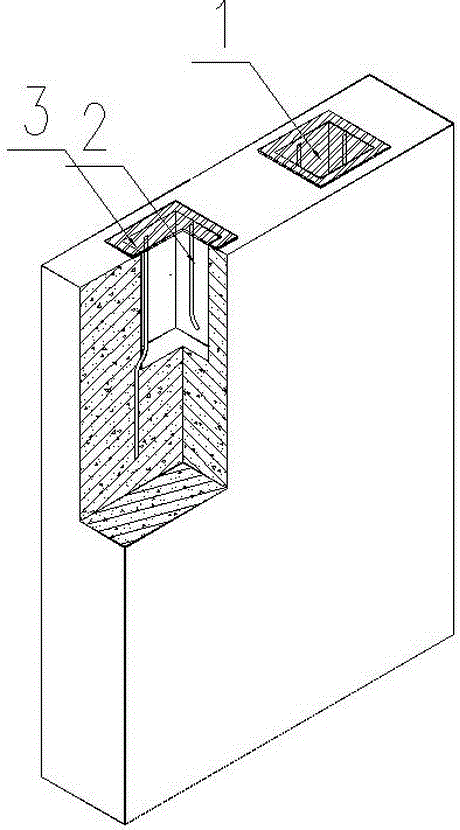

[0031] A kind of embodiment of the prefabricated reinforced concrete member that the present invention proposes, as figure 1 , there is a hole 1 in the prefabricated reinforced concrete member, the hole 1 is a non-through hole, and the steel bar 2 is set inside, and the steel bar 2 is anchored in the concrete on the side wall of the hole; the metal foil 3 is set at the mouth of the hole 1; for the convenience of expression, the metal foil in the figure 3 represents a transparent material. figure 1 The cut plane of the middle member is indicated by hatching, and the other steel bars of the prefabricated reinforced concrete member are not drawn.

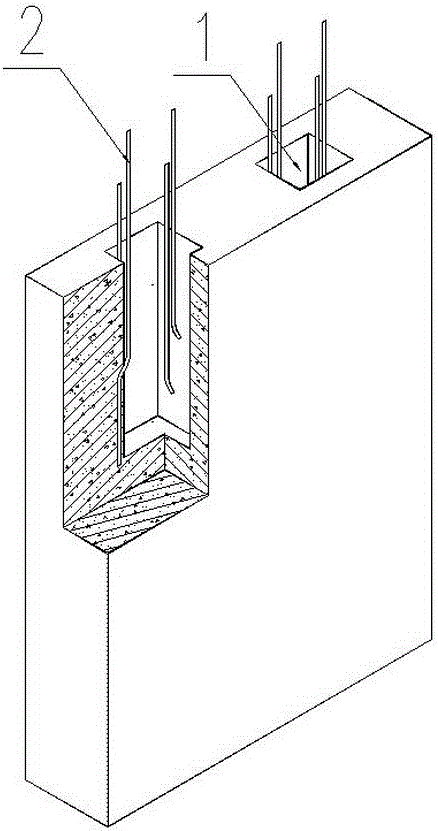

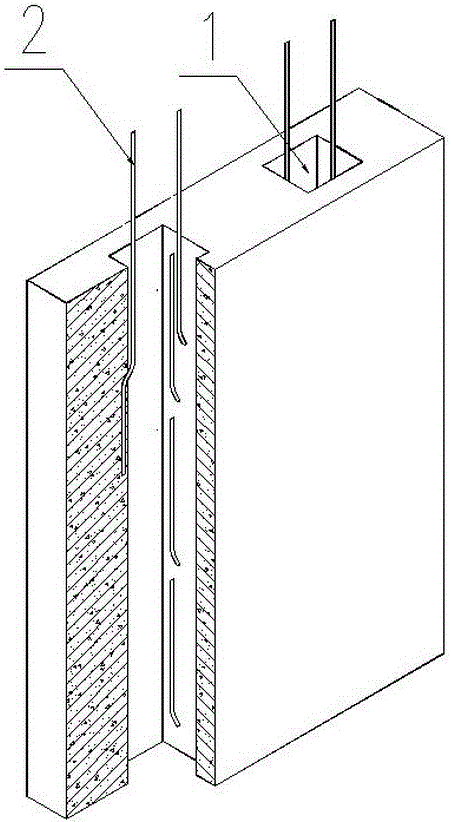

[0032] Another embodiment of the prefabricated reinforced concrete member proposed by the present invention, such as figure 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com