Zipper-type wall part and zipper key for producing the same

A zipper type, wall technology, applied in the field of zipper keys, can solve problems such as easy sliding down or falling off, failure to achieve a good wall, intermittent fracture of slurry, etc., so as to avoid uneven density, reduce quality, and prevent dislocation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: In Figure 8 Among them, an outer wedge-shaped groove 12 is arranged on the edge of the wallboard surface 14, and the periphery of the wallboard surface 14 is a side surface 9, and the recess between the side surface 9 and the outer wedge-shaped groove 12 is an inner wedge-shaped groove 13, and the two sides of the inner wedge-shaped groove 13 Four transverse grooves are respectively provided.

Embodiment 2

[0063] Embodiment 2: An outer wedge-shaped groove 12 is provided on the edge of the wallboard surface 14, and the periphery of the wallboard surface 14 is a side surface 9, and the recess between the side surface 9 and the outer wedge-shaped groove 12 is an inner wedge-shaped groove 13, and the inner wedge-shaped groove 13 At least one side, preferably both sides may be provided with two or more transverse grooves or protrusions.

[0064] At least one side of the inner wedge-shaped groove 13, preferably the grooves on both sides are transverse grooves, which can be transverse trapezoidal grooves, tapered grooves, hemispherical pits, trapezoidal grooves or rectangular grooves.

Embodiment 3

[0065] Embodiment 3: A zipper-type building wall panel. An outer wedge-shaped groove 12 is provided on the edge of the wall panel surface 14. The periphery of the wall panel surface 14 is a side surface 9, and the recess between the side surface 9 and the outer wedge-shaped groove 12 is an inner wedge shape. The groove 13, one or both sides of the inner wedge-shaped groove 13 may be provided with two or more transverse grooves or protrusions.

[0066] One side or two sides of the inner wedge-shaped groove 13 may be provided with a transverse trapezoidal column, a tapered column, a hemispherical mound, a table-shaped column or a rectangular column.

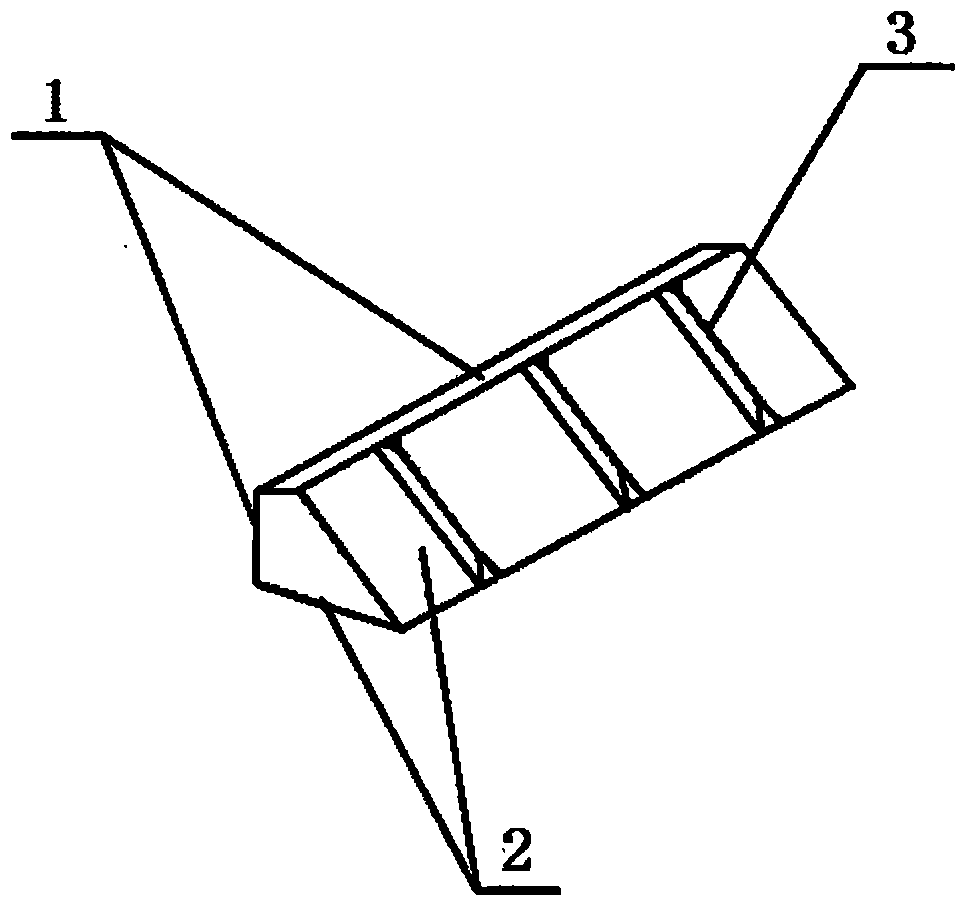

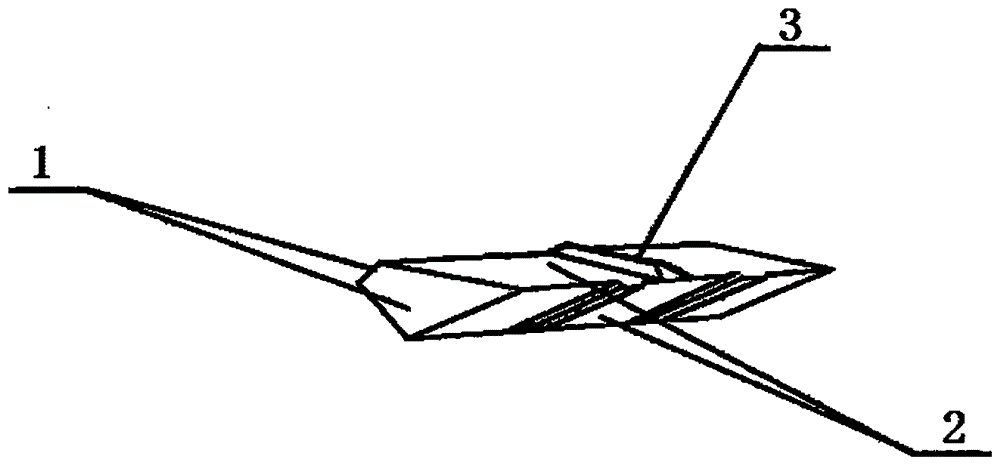

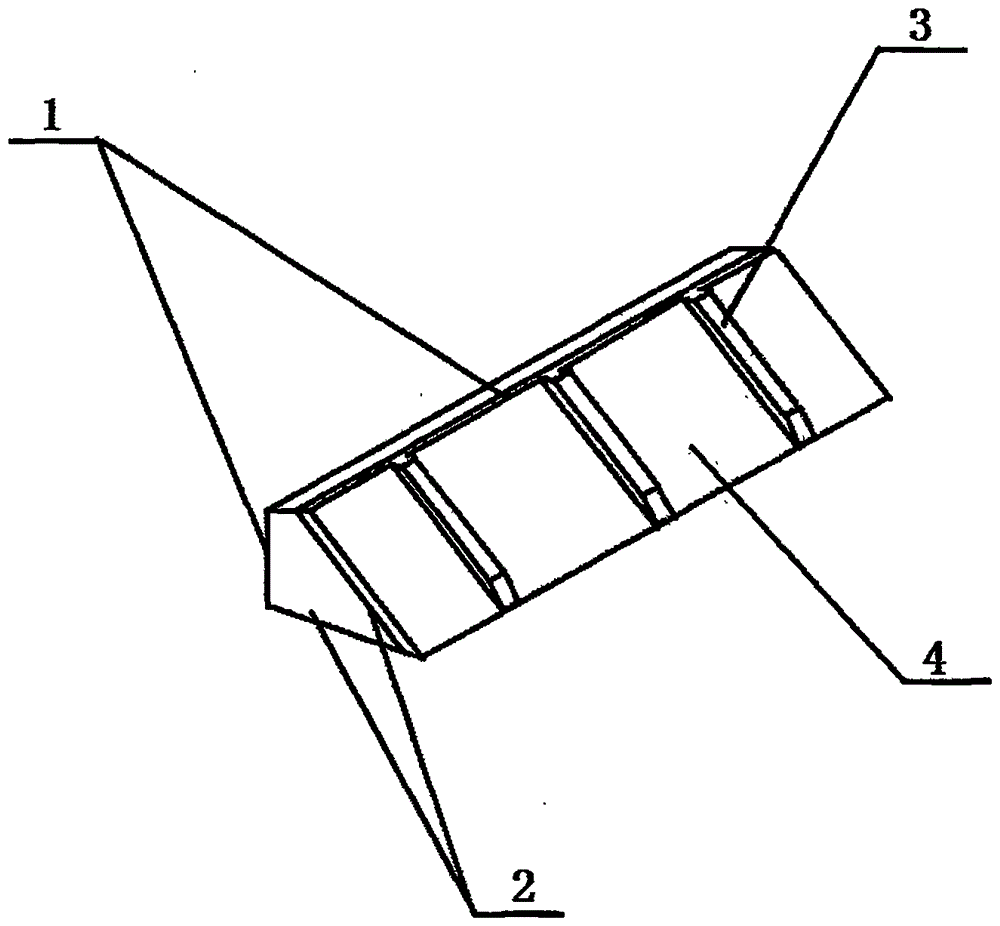

[0067] In the present invention, a zipper key used when making a zipper-type building wall panel, embodiment 1: a zipper key used when making a zipper-type building wall panel is a wedge-shaped cylinder, wherein two surfaces are perpendicular to each other, called The vertical surface 1 and the other surface are called notch surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com