Measurement-while-drilling electric drill device

A measurement-while-drilling and electric drilling technology, applied in measurement, support device, automatic control system of drilling, etc., can solve the problems of reducing work efficiency, unable to give the value of layer thickness, unable to give accurate value of drilling depth, etc. , to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

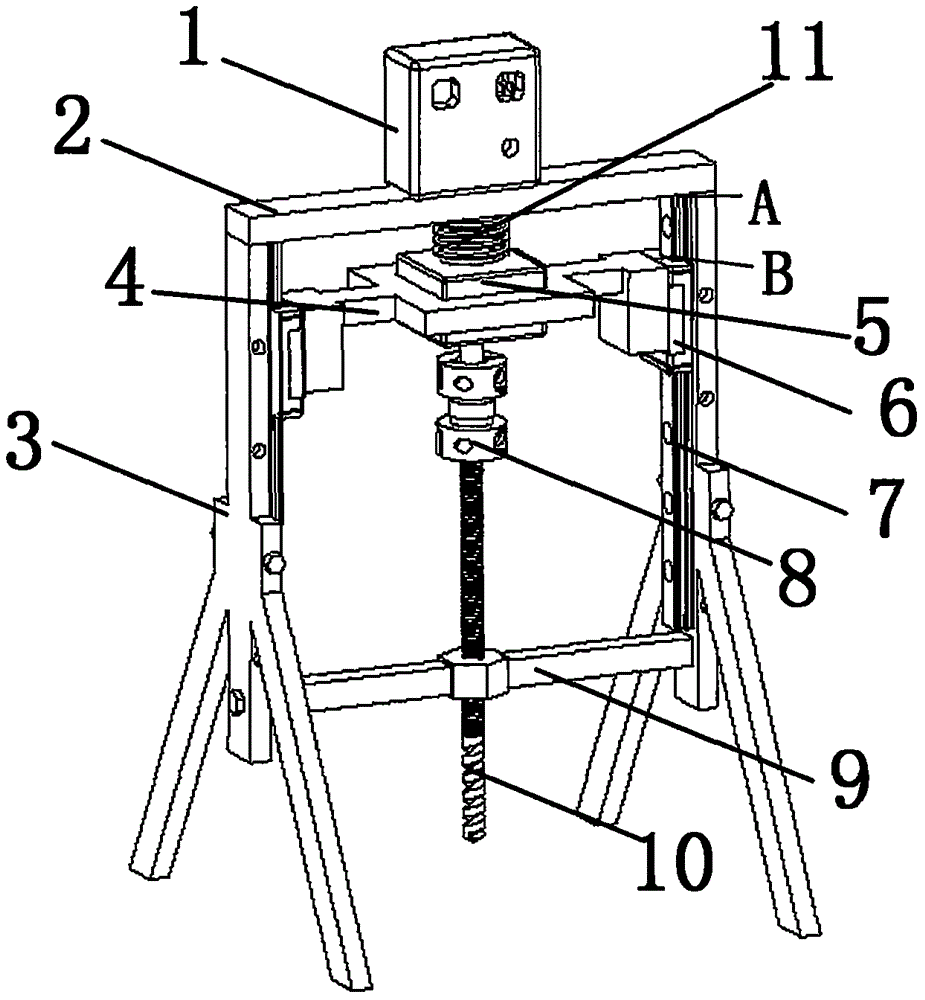

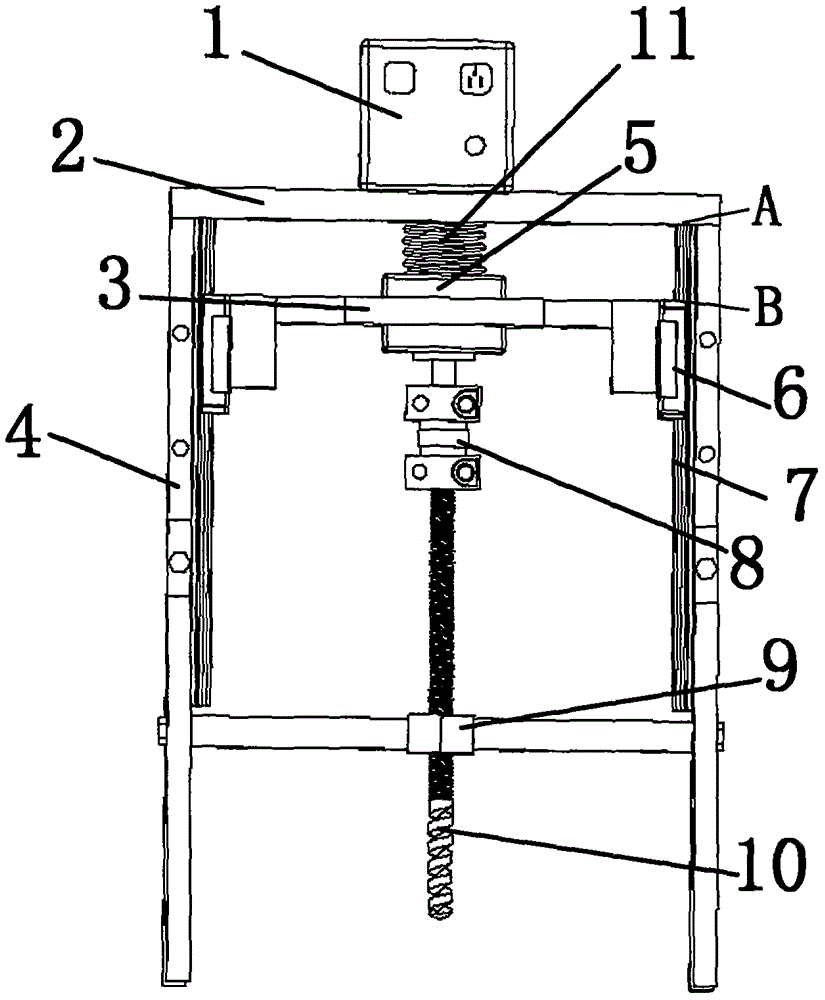

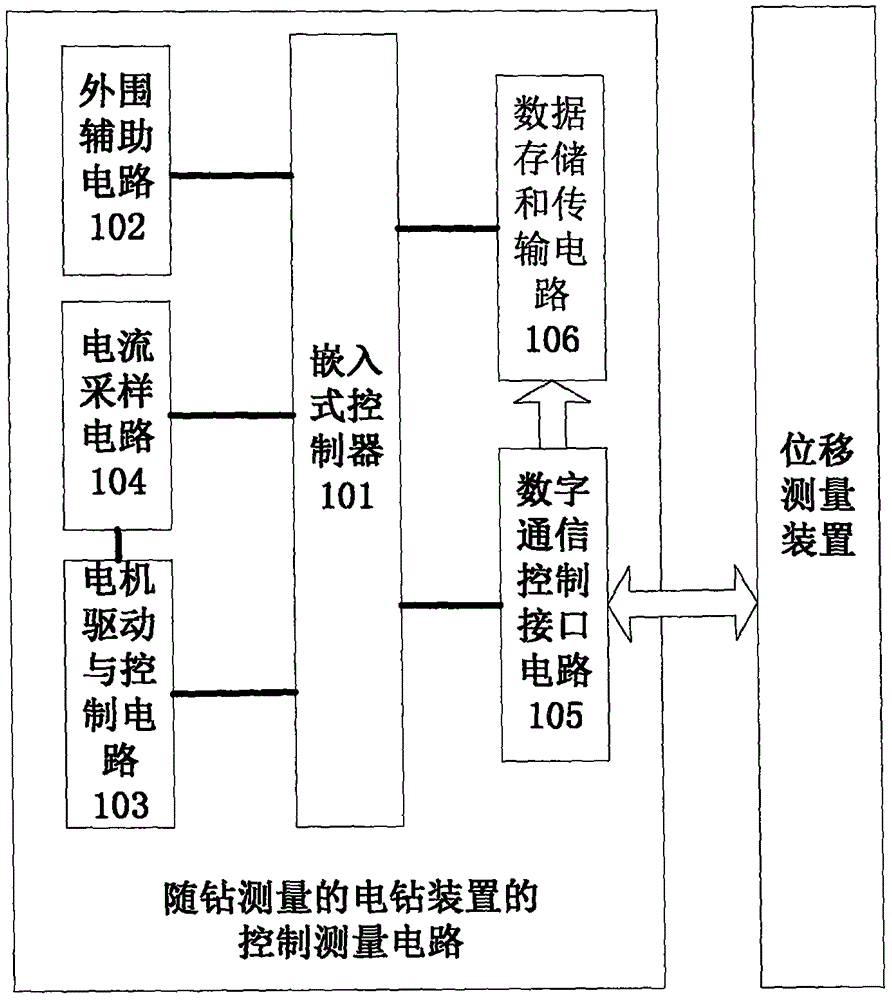

[0023] refer to figure 1 and 2 As shown, a measurement-while-drilling electric drill device of this embodiment includes a structure, a control measurement circuit, a displacement measurement device, and a power supply and power distribution device.

[0024] The structure of the electric drill device for measuring while drilling in this embodiment includes a circuit box 1, a top bracket 2, a side bracket 3, a motor fixing rod 4, a motor 5, a chute 6, a slide rail 7, a drill bit fixing clip 8, and a special-shaped nut rod 9. Double threaded drill bit 10 and thrust spring 11. The bottoms of the two side supports 2 are connected to the object to be measured. When the electric drill is working, the double-threaded drill bit 10 is kept perpendicular to the surface of the object to be drilled. Described double-threaded drill bit 10, the thread near the outer end of the drill bit is a twist drill thread suitable for rotating cutting objects, and the part connected to the motor 5 and...

Embodiment 2

[0030] A kind of electric drill device of measuring while drilling of the present embodiment, its basic structure is identical with embodiment 1, and its difference is: displacement measuring device adopts laser rangefinder, measures the length of point A to B of slide rail 7, its The advantage is that the accuracy of measuring hole depth or thickness is high.

Embodiment 3

[0032]A kind of electric drill device for measuring while drilling in this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that: the displacement measuring device adopts an encoding counter, and the encoding counter is installed on the drill bit fixing clip 8 to measure the forward direction of the double-threaded drill bit 10. And the number of turns of reverse rotation, according to the pitch of the double-thread drill bit 10 bolt threads, calculate the length from point A to point B of the slide rail 7. Its advantage is that the precision of measuring hole depth or thickness is high. In addition, the motor drive control circuit that controls the measurement circuit adopts a remote control method, and the data storage and transmission circuit adopts a wireless transmission method.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap