Ventilation transportation system for single-inclined-shaft multi-face tunnel construction

A tunnel construction and transportation system technology, applied in the field of traffic engineering, can solve problems such as the difficulty in arranging multiple large-diameter air ducts, aggravating air pollution in the tunnel, and increasing the difficulty of construction ventilation, so as to improve the ballast output speed and comprehensive The effect of driving efficiency, ensuring occupational health, and improving construction efficiency and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in combination with specific embodiments.

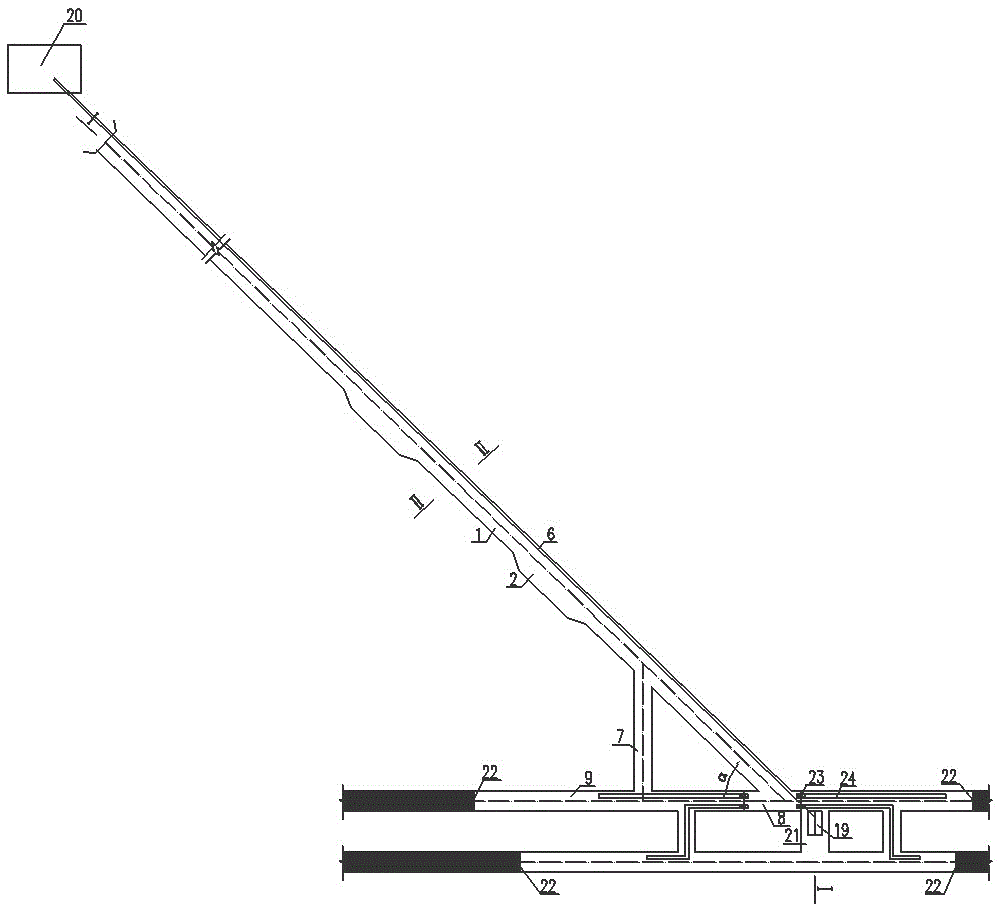

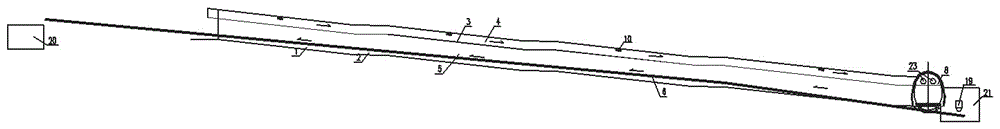

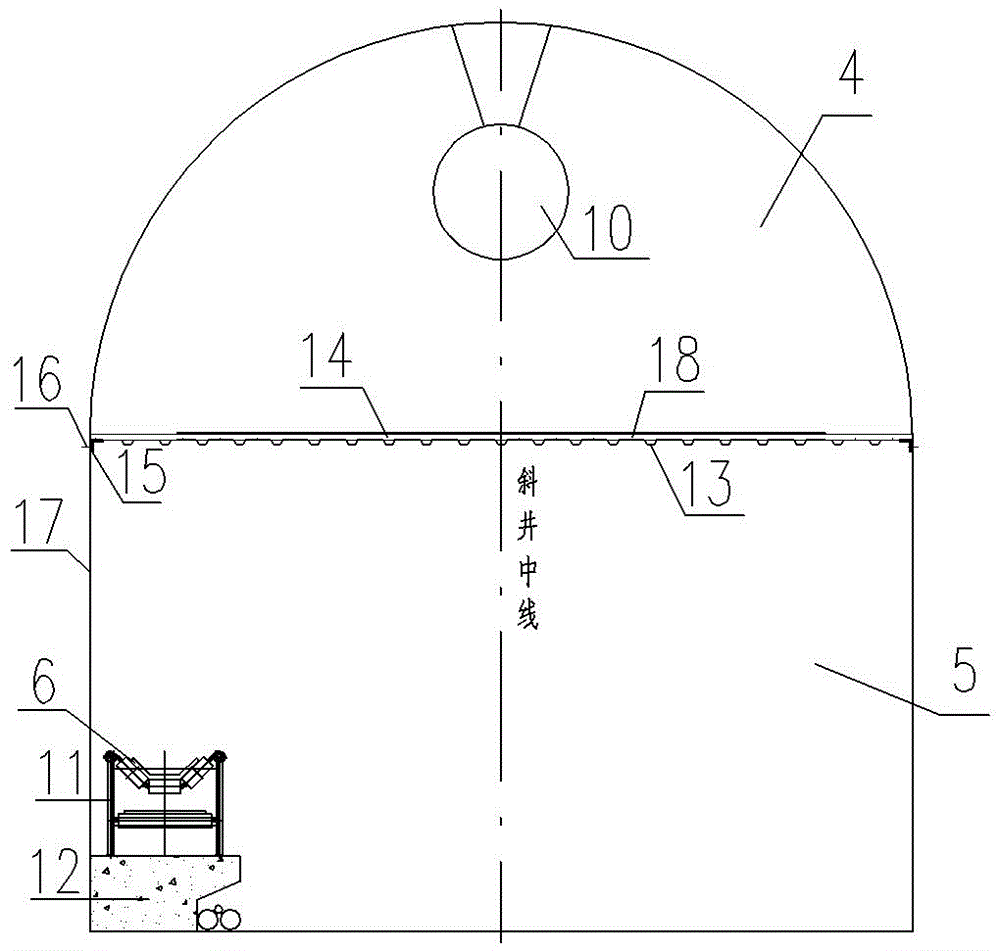

[0032] The ventilating transportation system for the construction of multi-face tunnels in a single inclined shaft according to the present invention comprises a tunnel 9, an inclined shaft and a dumping ground 20 at the exit of the inclined shaft, the tunnel 9 is a parallel two-tube tunnel, and the inclined shaft and one of the tunnels connected to each other, the inclined shaft undertakes the construction of the four tunnel faces 22 of the two-pipe tunnel at the same time. The shaft 1 of the inclined shaft is provided with a transverse intermediate partition 3, which is located in the middle of the shaft 1. The intermediate partition 3 divides the section of the shaft 1. It is divided into air supply duct 4 and flue exhaust duct 5 up and down. The upper part is an air duct 4 for entering fresh air, and the lower part is a flue exhaust duct 5 for discharging dirty air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com