Starting method of high-speed high-power compressor

A compressor and high-power technology, which is used in the field of high-speed and high-power compressor startup, can solve the problems of shortened stable operation time, inability of moving parts to meet lubrication requirements, and reduced reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

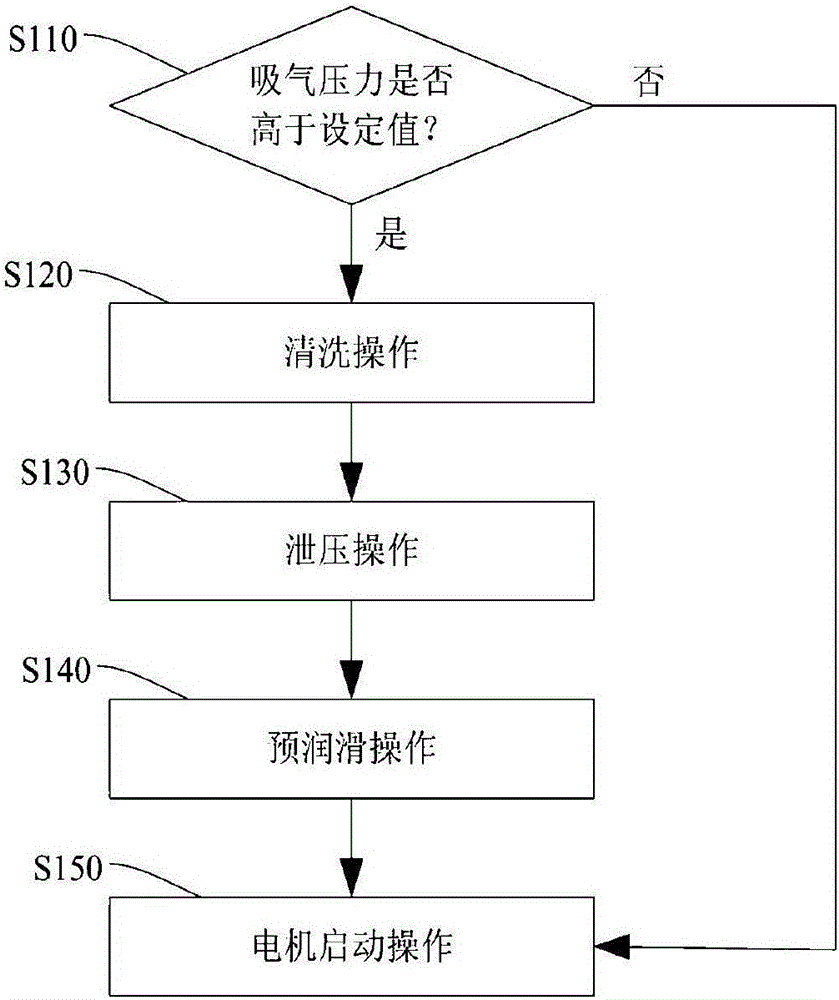

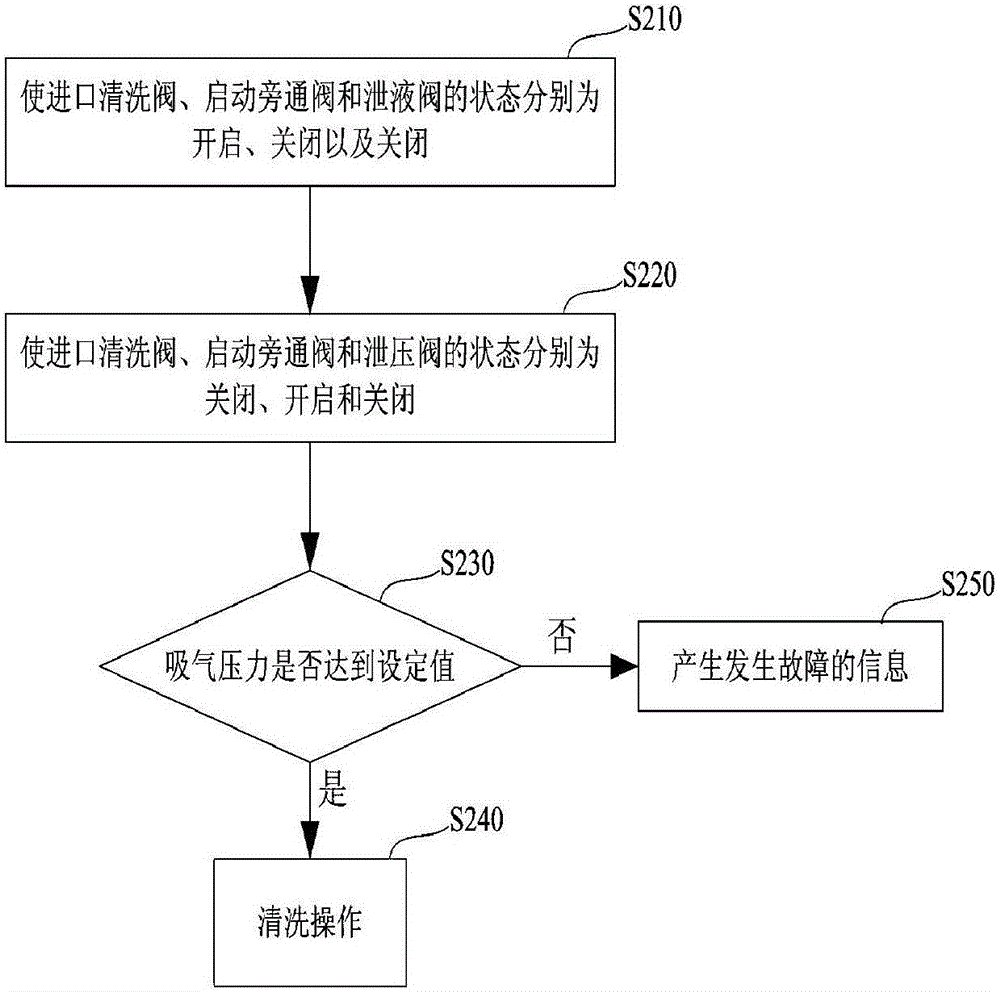

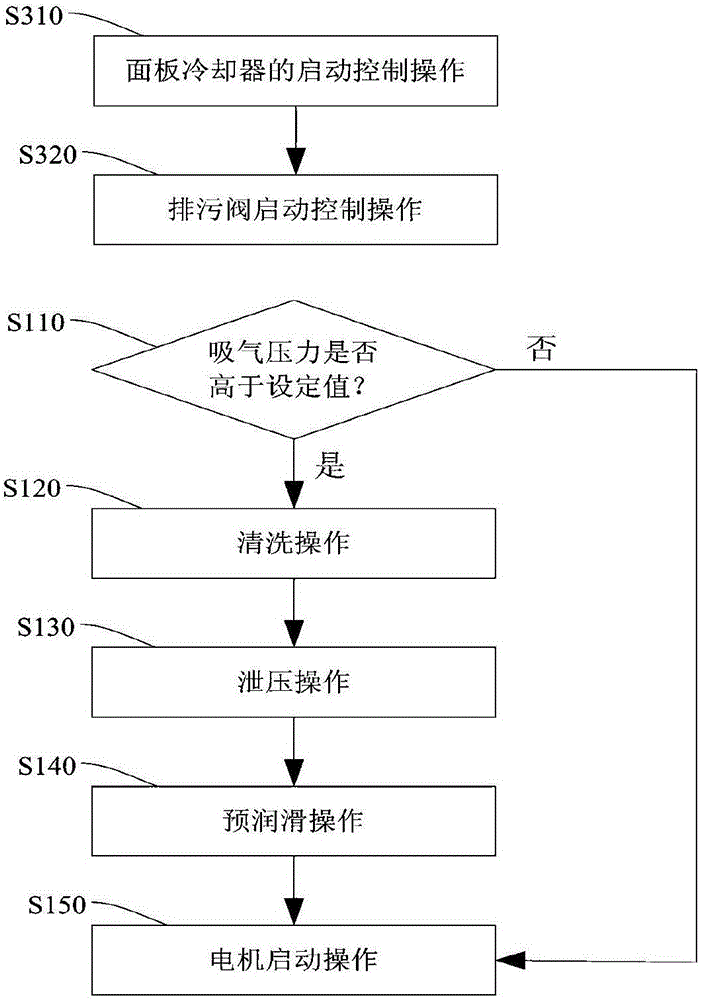

[0029] in reference to figure 1 Before describing the start-up of the high-speed and high-power compressor, briefly introduce various valves to the compressor (hereinafter referred to as "compressor") according to an exemplary embodiment of the present invention. The valves include: an inlet purge valve connected to the compressor The valve on the air intake process pipeline of the compressor is used to control the intake air cleaning before the compressor unit starts; the inlet suction valve is connected to the valve on the air intake process pipeline of the compressor, and is used to clean the intake air when the compressor is loaded and unloaded. control; start the bypass valve, connected to the compressor unit intake and final exhaust process pipeline, mainly used for process gas backflow control; exhaust valve, connected to the compressor final exhaust pressure process pipeline, mainly used It is used to control the final exhaust of the compressor; the pressure relief val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com