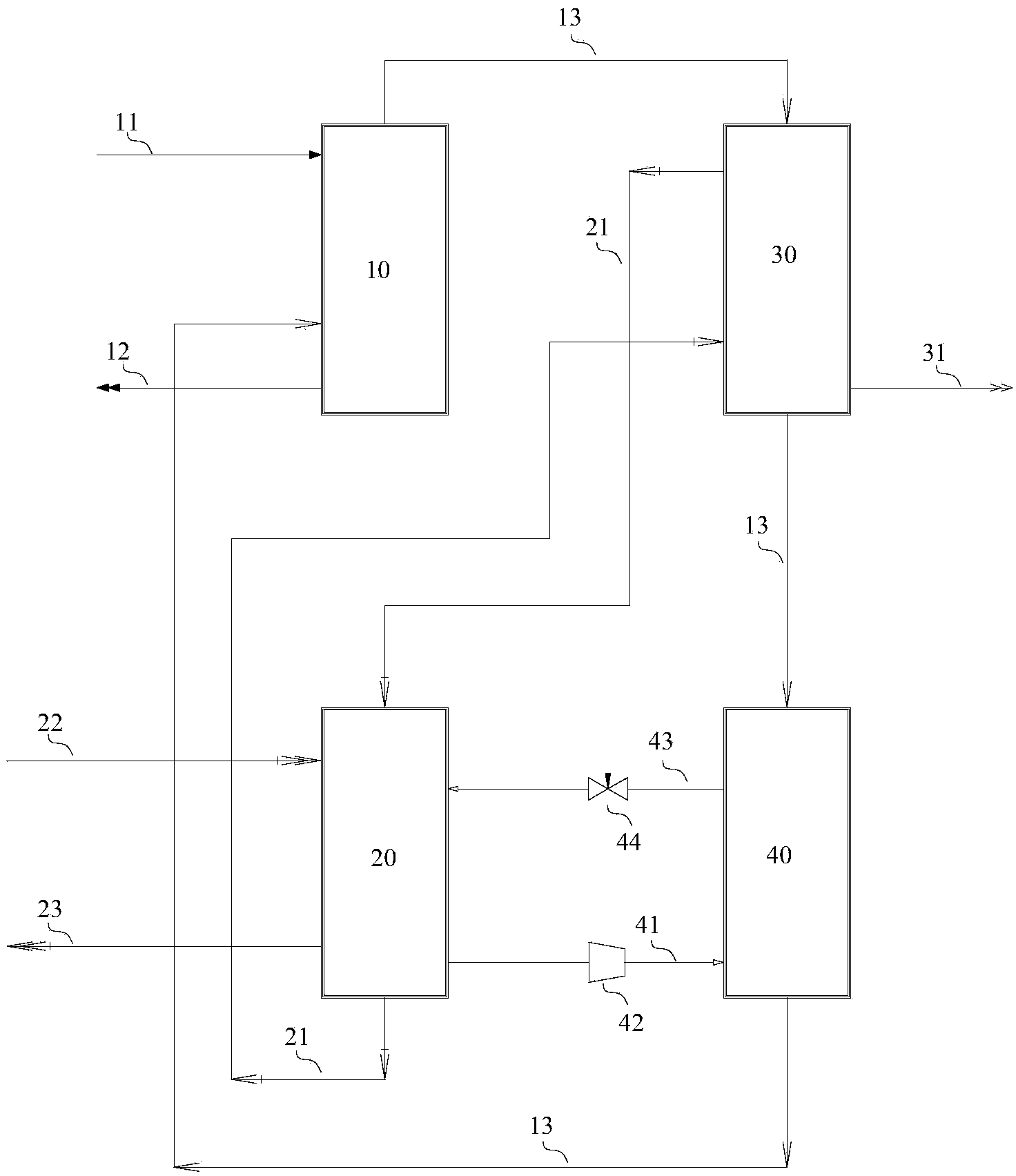

Gas cycling evaporation method and device

A gas circulation and evaporation device technology, applied in the direction of evaporation, separation methods, chemical instruments and methods, etc., can solve the problems of high moisture content of solid materials at the bottom of the evaporation chamber, failure to consider low-temperature waste heat utilization, system thermal efficiency and stability decline, etc. , to achieve the effects of saving evaporation energy consumption, realizing waste reduction, and reducing the amount of boiling point substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] A fine chemical sewage biochemical treatment sludge daily output is about 20 tons / day (moisture content is about 99%). Since biochemical sludge is a national hazardous waste, it needs to be dehydrated by the enterprise and sent to the incineration station for treatment. Considering that the dehydrated biochemical sludge is refractory and toxic (biochemical sludge absorbs highly active organic compounds), and further considering that the moisture content of the sludge sent to the incineration station is highly related to the incineration cost, the technical solution of this application was finally selected (1 first evaporator unit, 2 first condenser units, 1 second condenser unit, 2 second evaporator units, 1 compressor unit) are dehydrated and sent to the incineration plant for treatment. The circulating gas adopts ambient air, the external heat medium adopts the quenching water of the incineration station (the temperature is about 60-70°C, and the flue gas is quenched ...

Embodiment 3

[0041] After a chemical product is extracted by ethanol, ethanol and products need to be separated, and the production amount is about 40 tons per day. A common measure is vacuum distillation, and the treatment cost is about 180 yuan / ton of alcohol. Adopt the technical scheme of the present application (1 first evaporator unit, 4 first condenser units, 1 second condenser unit, 2 second evaporator units, 2 compressor units), the circulating gas is nitrogen (The purpose is explosion-proof), the external source heat medium is steam condensed water in the factory area (40~50°C), the internal source heat medium temperature is -15~-5°C, and the temperature of the circulating gas is cooled from 45±2°C in the first condenser unit to -10±2°C. In the second condenser unit, the temperature is raised from -10±2°C to 68±2°C, and the final separation cost is 53Kwh / ton of ethanol. After the ethanol is subsequently dehydrated to within 500ppm, it continues to be recycled, and the ethanol con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com