Coke oven denitration pipe and preparation method thereof

A technology of denitrification and coke oven, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve problems such as inability to adapt to intermittent air blowing, inability to produce ceramic tubes, and poor thermal shock stability of ceramic tubes. , to achieve the effects of good thermal shock stability, long stable running time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

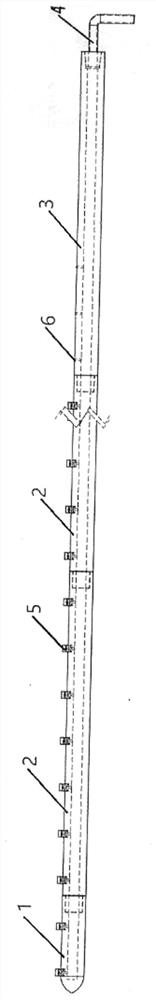

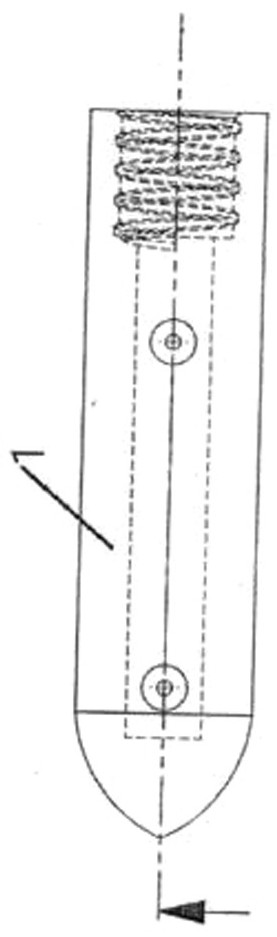

[0050] Embodiment 1. A coke oven denitrification pipe, which includes a denitrification pipe head 1, several middle sections of denitrification pipes 2, a denitrification tailpipe 3, metal joints 4, and nozzles 5. The denitrification pipe head 1, several middle sections The middle section 2 of the denitration pipe and a denitration tailpipe 3 are sequentially connected by means of screw connection; at least one row of discontinuously distributed nozzles 5 is distributed on the whole denitration pipe.

Embodiment 2

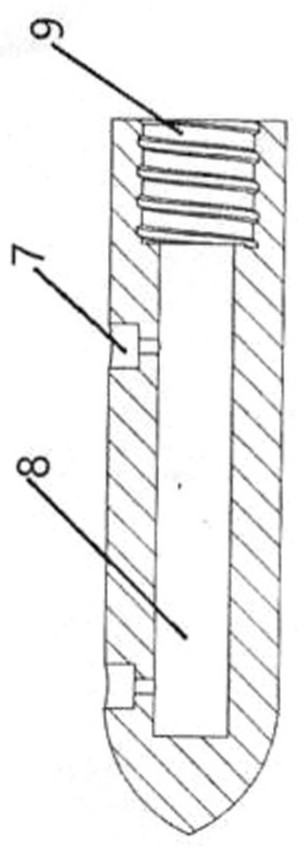

[0051] Embodiment 2. One end of the denitration pipe head 1 is closed, and the other end is provided with threads; the middle section 2 of the denitration pipe is provided with a female thread 9 and a male thread 10 at both ends of each section, and the middle section 2 of the denitration pipe is provided with There is an internal gas channel 8, and the middle section 2 of the denitrification pipe is provided with a spray hole 7 which can be inlaid with a nozzle; the denitrification tailpipe 3 is provided with a thread at one end, and the other end is connected to an external metal joint 4 pipe fittings, and the middle part of the denitrification tailpipe 3 is provided with an internal The gas passage 8; the denitrification tailpipe 3 is provided with an injection hole 6.

Embodiment 3

[0052]Embodiment 3, the female thread 9 is directly formed by isostatic pressing, and the male thread 10 is processed by a lathe; the diameter of the head of the male thread 10 is smaller than the diameter of the tail, and the diameter of the head of the female thread 9 is greater than the diameter of the tail; the tail of the male thread 10 is set There is a knife relief groove, and the length of the knife relief groove is ≥5mm, which is convenient for assembling the denitration pipe, and sealing the seam with ceramic fiber rope or ceramic fiber mat or high-temperature sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com