Two-stage type planet gear automatic transmission

A technology for automatic transmissions and planetary gears, applied in gear transmissions, vehicle gearboxes, belts/chains/gears, etc., can solve the problems of insufficient compact structure of automatic transmissions, many actuators changing, and many actuators, etc., so that it is not easy to move Effects of less interference, fewer actuator changes, and fewer actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

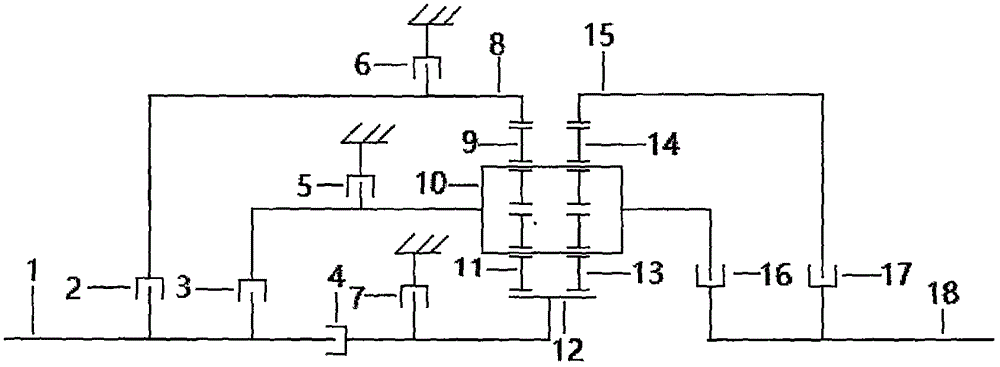

[0011] figure 1 As shown, it involves a two-stage planetary gear automatic transmission, including: a front row ring gear 8, a front row sun gear, a front row planet carrier, a front row first planetary gear 11 and a front row second planetary gear 9 Front row double-stage planetary gear mechanism; rear row double-stage planetary gear mechanism composed of rear row ring gear 15, rear row sun gear, rear row planet carrier, rear row first planetary gear 13 and rear row second planetary gear 14; Wherein, the front sun gear and the rear sun gear are made into a common front and rear sun gear 12, and the front planet carrier and the rear planet carrier are made into a common front and rear planet carrier 10;

[0012] The first output end of the power input shaft 1 is respectively connected with the input ends of the first clutch 2, the second clutch 3 and the third clutch 4; the output end of the first clutch 2 is connected with the front ring gear 8, so The output end of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com