Deep purifying and follow-up exhausting device for lampblack and purifying and follow-up exhausting integrated range for lampblack

A deep purification and oil fume technology, which is applied in combined devices, oil fume removal, household stoves, etc., can solve the problems of easy deposition of oil fume in the purifier, poor purification effect of oil fume, secondary pollution of oil pollution, etc., and achieves low cleaning and maintenance frequency and convenient The effect of concentrated treatment and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

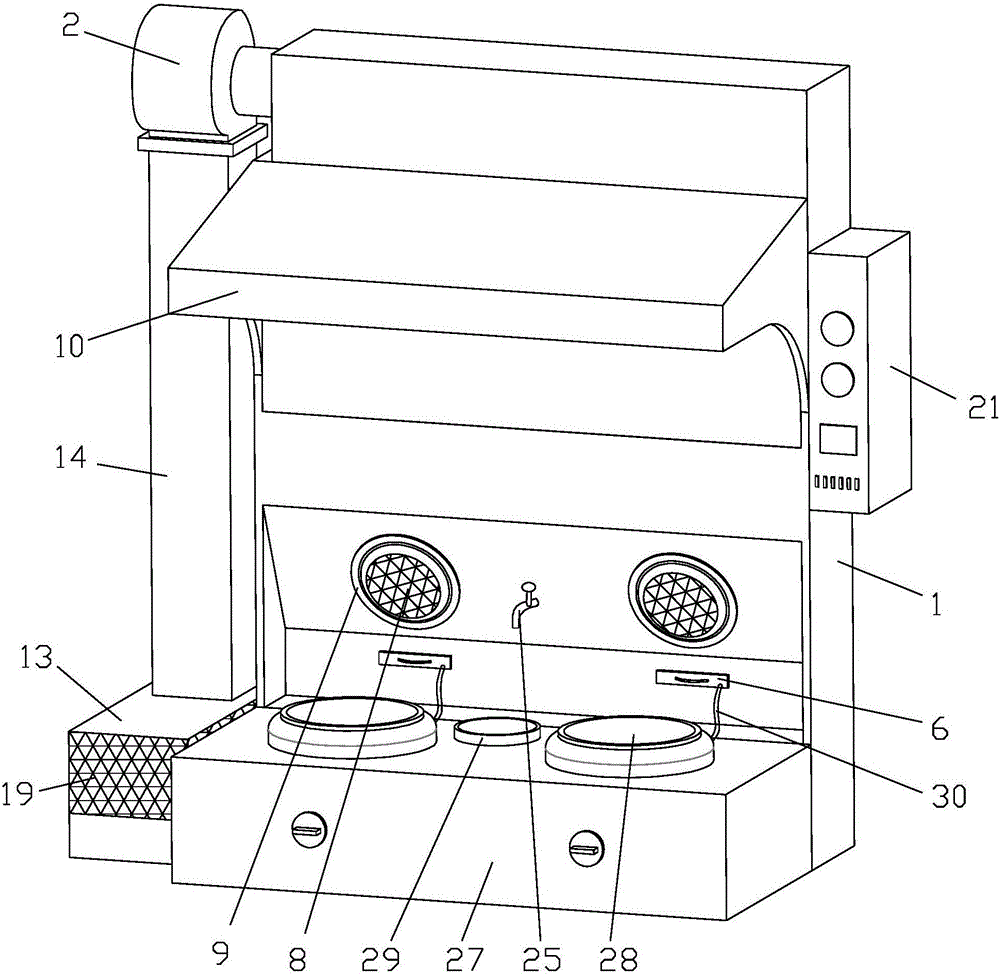

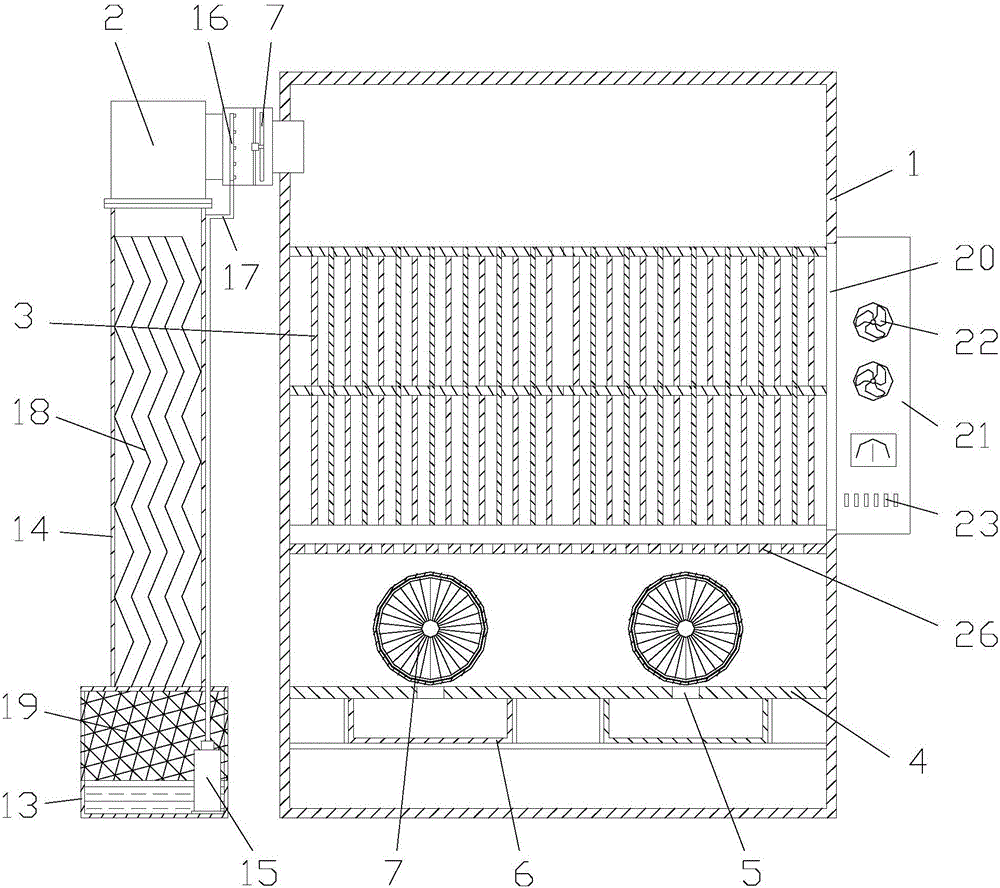

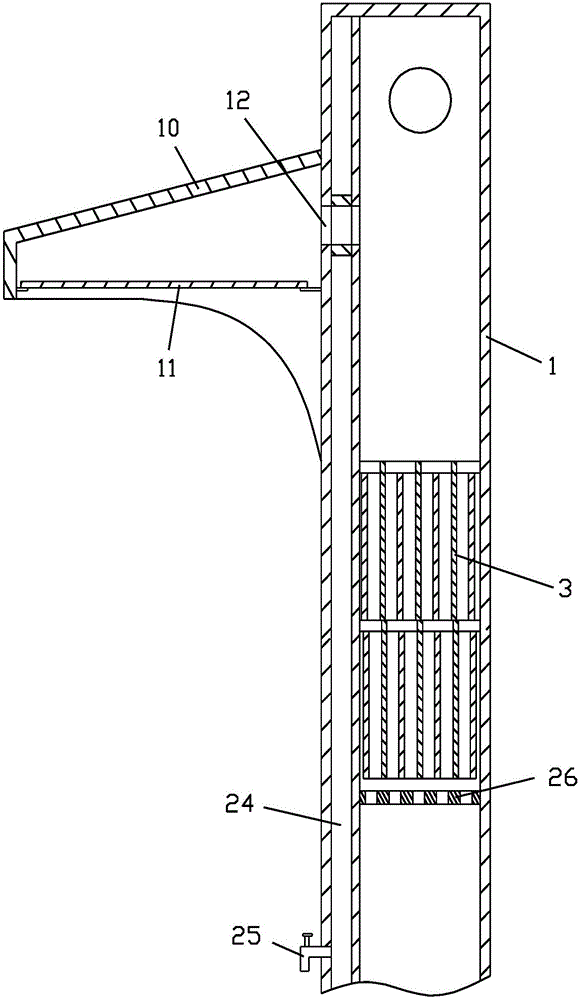

[0031] As shown in the figure, the oil fume deep purification exhaust device of this embodiment includes a casing 1 and an exhaust fan 2. There is an oil fume passage in the casing, and the outlet of the oil fume passage is arranged on the upper part of the casing. The exhaust fan The air inlet of the cabinet communicates with the outlet of the oil fume channel. The oil fume inlet is arranged on the front lower part of the casing, and the front of the casing is opposite to the stove. There is an oil fume filter device, and a honeycomb electric field 3 is arranged in the oil fume channel;

[0032] The cathode needles of the honeycomb electric field are arranged vertically;

[0033] The casing is provided with an oil receiving plate 4 for collecting oil dripping from the honeycomb electric field, and the oil receiving plate is provided with an oil discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com