Laminated finned tube heat exchanger

A finned-tube heat exchanger, stacking technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of no mass production, heat exchanger design, increased processing workload, etc. , to achieve the effect of convenient and simple installation, shorten the production cycle, and reduce the cost of production design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described The implementations are only some of the implementations of the present application, not all of them. Based on the implementation manners in this application, all other implementation manners obtained by persons of ordinary skill in the art without creative efforts shall fall within the scope of protection of this application.

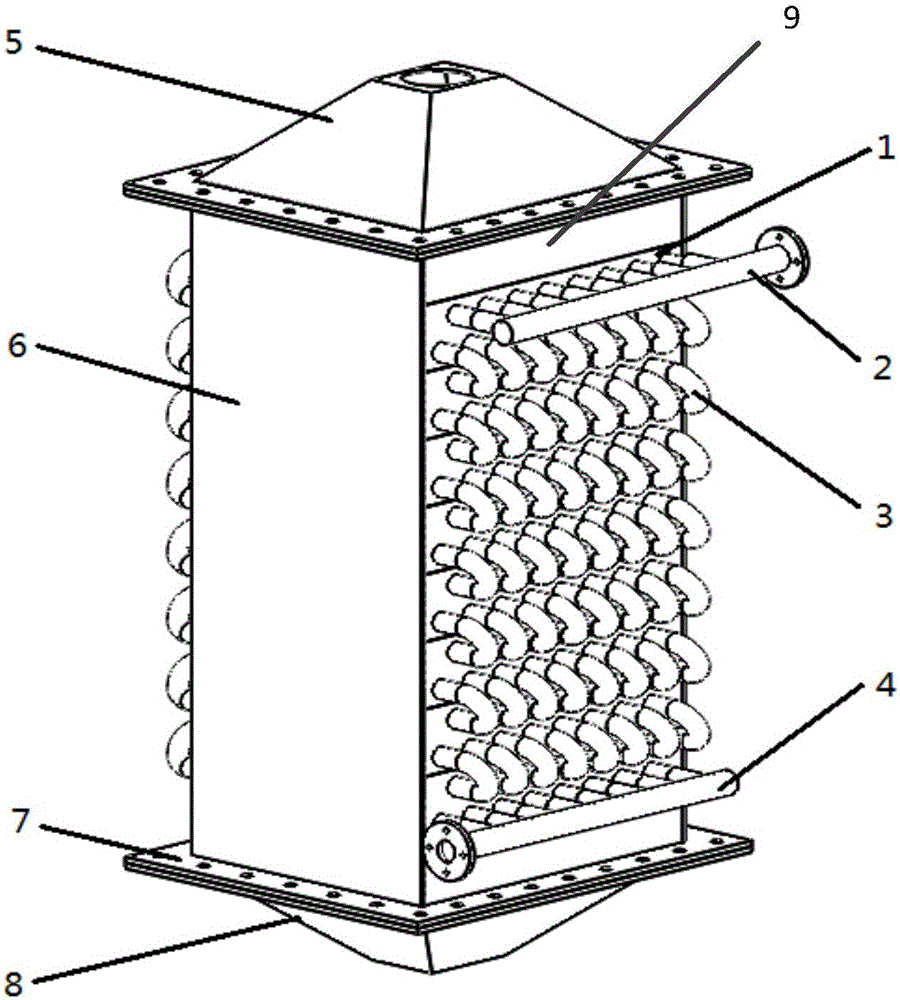

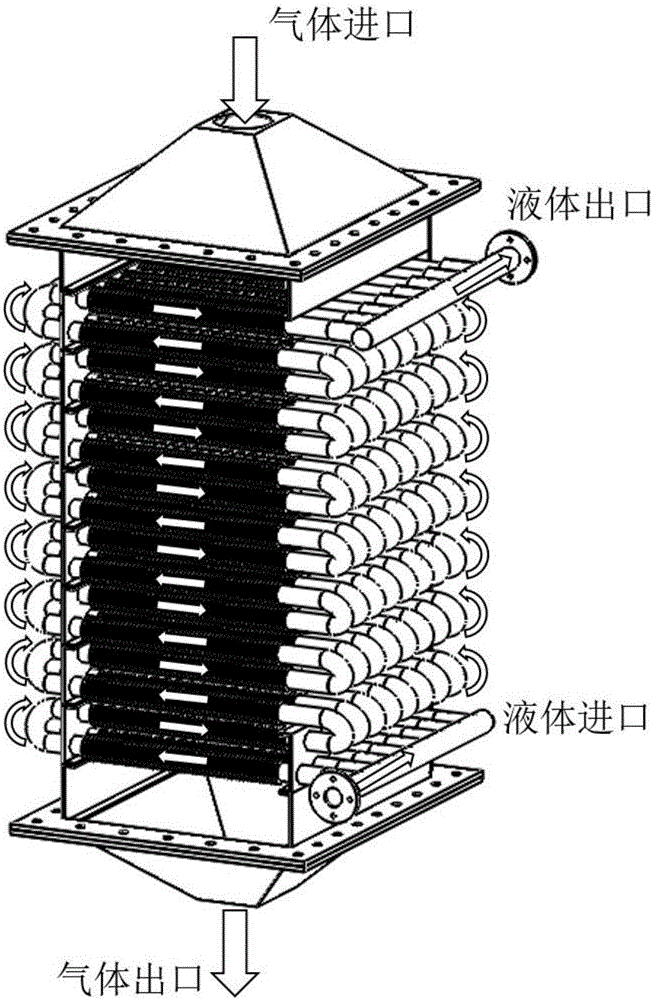

[0021] Such as figure 1 As shown, the laminated finned tube heat exchanger includes a plurality of heat exchange units 1, a liquid inlet main pipe 4, a liquid outlet main pipe 2, several bent pipes 3, side plates 6, support tube plates 9, upper air ducts 5, downwind Road 8 and Air Road Flange 7.

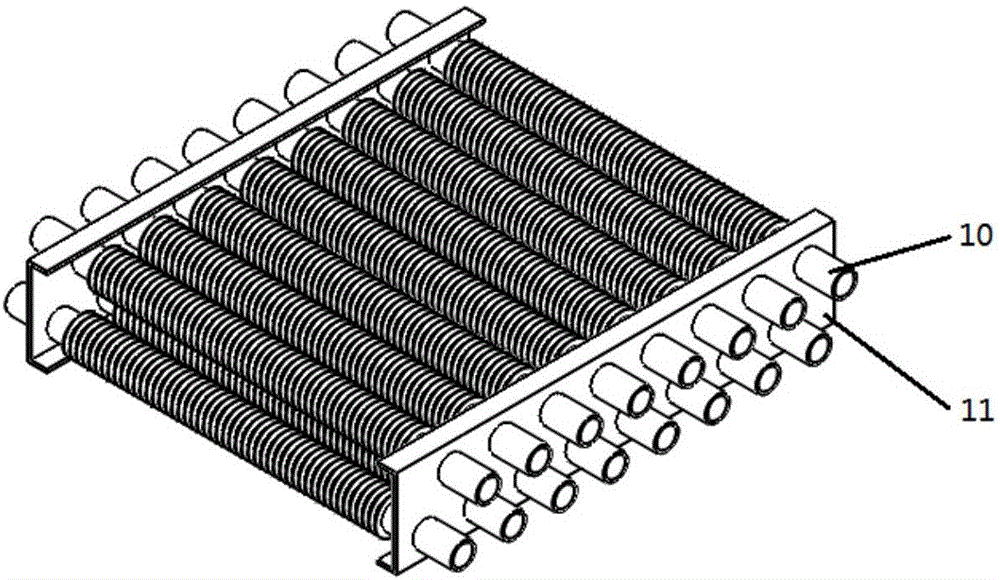

[0022] The st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap