Blowing expansion type plate heat exchanger and manufacturing method thereof

The technology of plate heat exchanger and metal plate is applied in the field of inflation plate heat exchanger and heat exchanger for water heater, which can solve the problems of long process flow of condensing system, affecting water quality, poor system operation performance, etc., and achieves convenient manufacturing process. , Improve the efficiency of energy efficiency utilization, the effect of fast and efficient delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

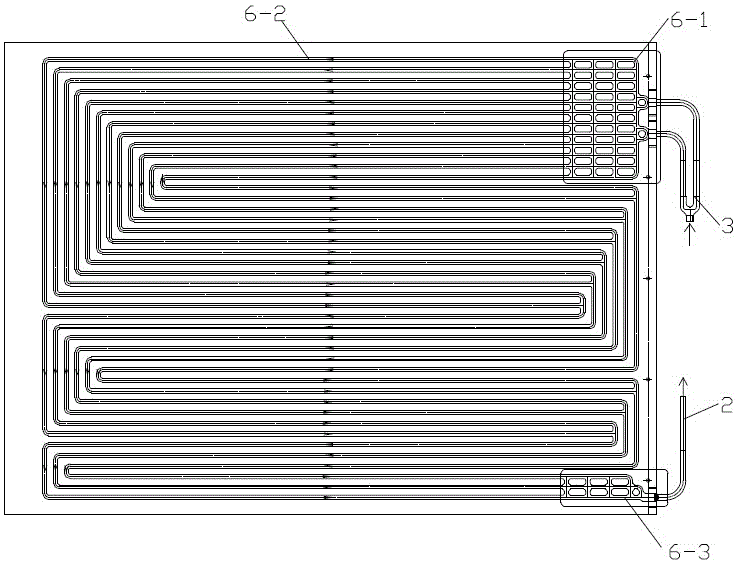

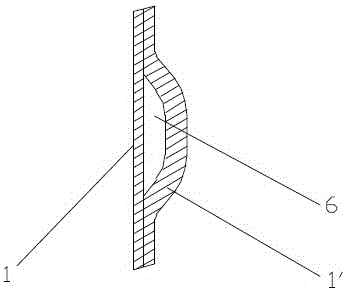

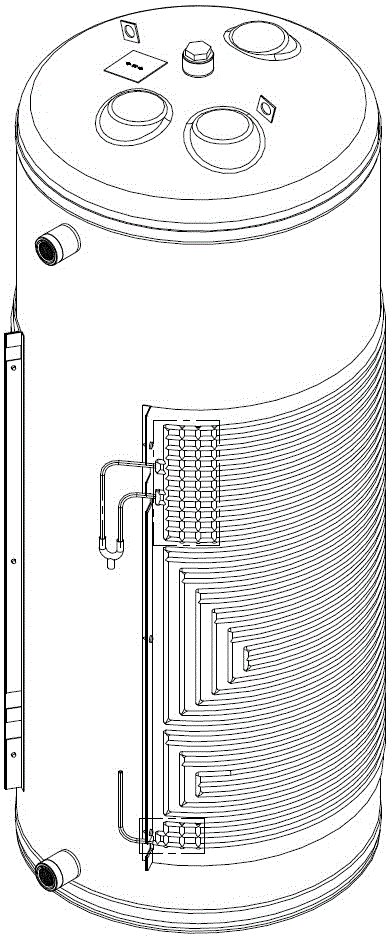

[0024] The blown plate heat exchanger of this embodiment is as figure 1 , figure 2 As shown, it is formed by combining inner and outer two-layer aluminum plates 1, 1', and the outer layer aluminum plate 1' has ribs forming a roundabout flow channel 6. The circuitous channel includes an inlet confluence channel 6-1 connected with the inlet pipe 3 and an outlet confluence channel 6-3 connected with the outlet pipe 2. The end of the inlet confluence channel 6-1 away from the inlet pipe 3 leads to a parallel intermediate flow channel 6- 2. The parallel intermediate flow channel 6-2 forms a roundabout flow channel after several right-angle turns, and finally connects to the outlet pipe 2 through the outlet converging channel 6-3. The parallel intermediate channel 6-2 condenses after each turning, so that the quantity after each turning gradually decreases, so after the original gaseous heat exchange medium gradually changes into a gas-liquid two-phase flow, the flow channel can b...

Embodiment 2

[0034] The basic structure of the blown plate heat exchanger in this embodiment can be seen in Embodiment 1, the main differences are as follows Figure 4 As shown, the channel number of the inlet confluence channel 6-1 increases from the inlet pipe 3 to both sides according to the natural progression; the number of the outlet confluence channel 6-3 decreases toward the lowest outlet pipe 2 according to the natural progression. In addition, each parallel intermediate flow channel 6-2 also has a network structure. Therefore, the gaseous heat exchange medium gradually expands after entering the heat exchanger, which is conducive to the smooth entry of the heat exchange medium into the heat exchanger; and the low outlet structure of the heat exchange medium when it is output has a liquid storage effect, which makes it easy to separate out impurity gases and improve The stability of the system during the change of working conditions; the network structure of the intermediate flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com